Micro-electromechanical double-layer thin-film cell out-of-plane bending curvature test structure

A technology of double-layer film and test structure, which is applied in the direction of mechanical counter/curvature measurement, etc., can solve problems such as stress difference, achieve stable test process, low test equipment requirements, and stable test parameter values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

[0029] Attached below Figure 1~4 The present invention will be further described.

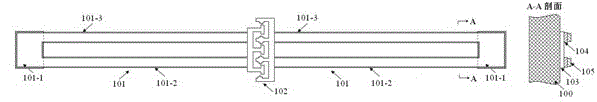

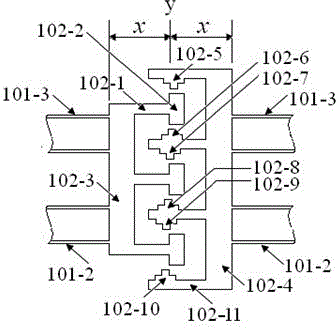

[0030] The invention proposes a testing structure for the off-plane bending curvature of a micro-electromechanical double-layer film unit. Such as figure 1 As shown, the test structure is composed of two double-layer membrane gate structures 101 and a difference measuring vernier 102 placed oppositely on the left and right.

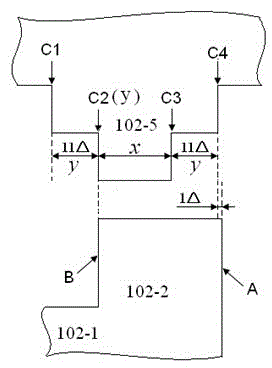

[0031] The difference measuring vernier 102 is composed of left and right parts. The core structure of the left half of the difference measuring vernier is a "T" structure, and the core structure of the right half is a "convex" structure. Each "T"-shaped head is in a certain alignment relationship with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com