Resonant frequency based composite cantilever beam mechanical parameter measurement method and device

A composite cantilever beam and resonant frequency technology, which is applied in the field of composite cantilever beam mechanical parameter measurement and composite cantilever beam mechanical parameter measurement based on resonant frequency, can solve the problem that the mechanical parameters of single-layer film materials cannot be directly applied to multi-layer films, etc. The effect of solving the problem of mechanical parameter measurement, low test equipment requirements, and stable test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

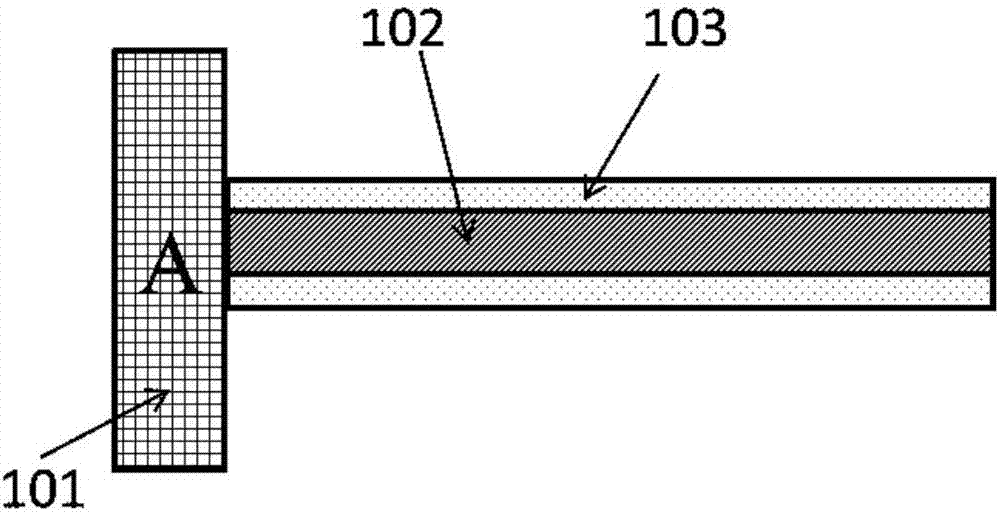

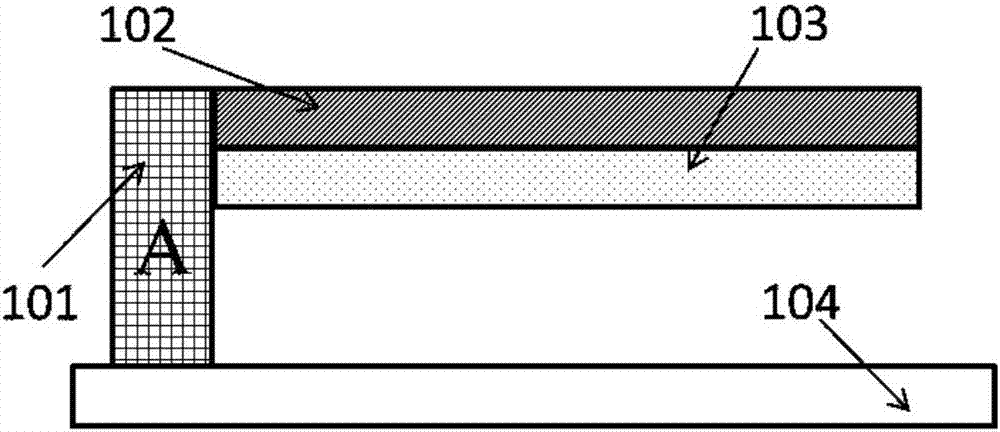

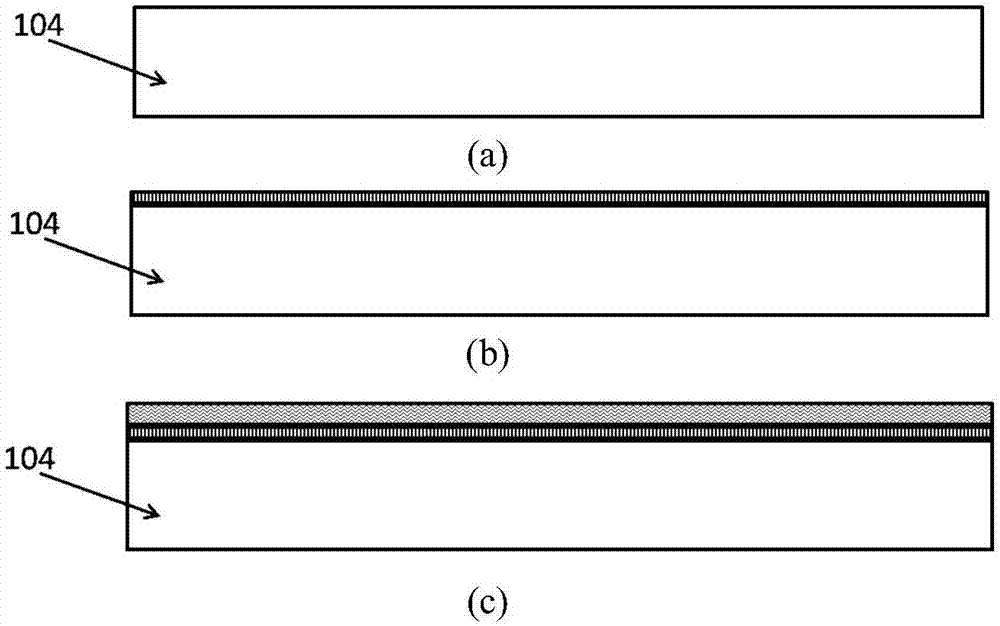

[0028] Aiming at the online measurement of the mechanical parameters of the multilayer composite thin film structure, the idea of the present invention is to obtain the relationship between the first-order resonance frequency of the multilayer composite cantilever and parameters such as material properties and structural dimensions by constructing a resonance model of the multilayer composite cantilever beam. relationship, and use the form of solving equations to obtain the equivalent Young's modulus of each layer of the multi-layer composite cantilever beam at one time.

[0029] In order to facilitate the public's understanding of the technical solution of the present invention, the theoretical principles of the technical solution of the present invention are first described in detail.

[0030] For a multilayer composite cantilever beam composed of at least two film structures, when the film width and thickness satisfy w i i , that is, when the cantilever beam is a narrow b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com