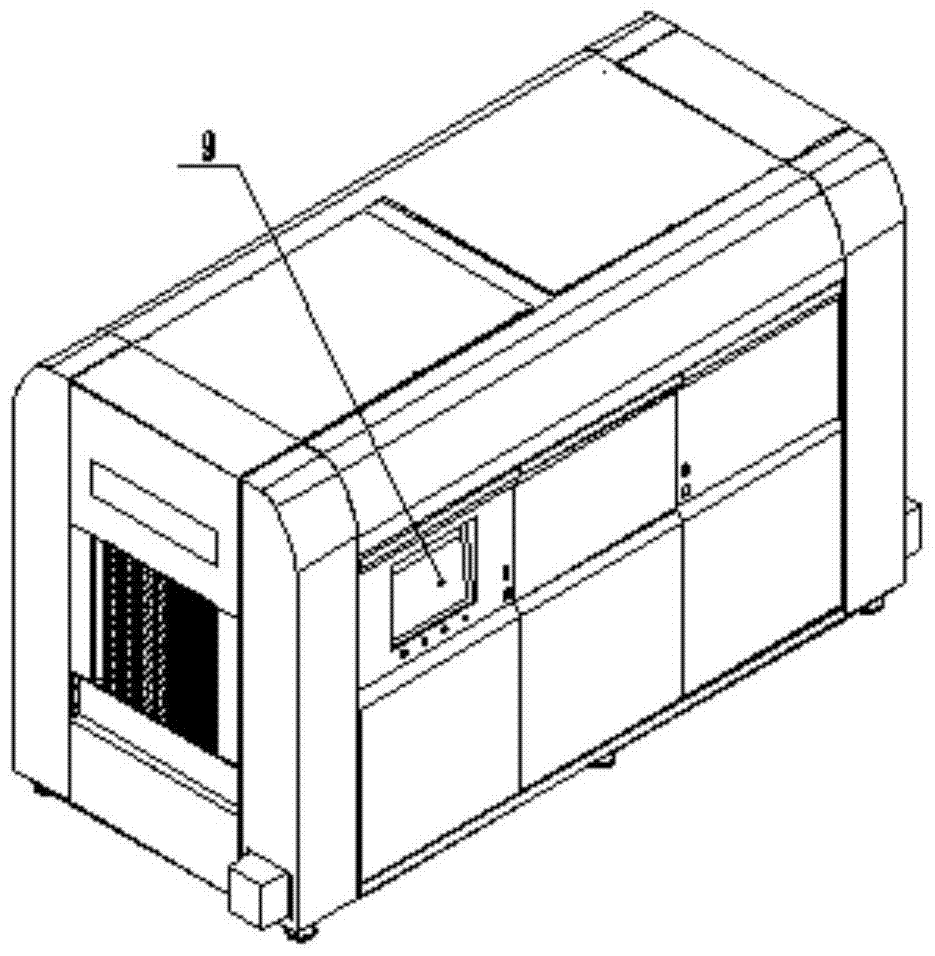

RFID detection channel for warehousing logistics

A detection channel and warehousing logistics technology, which is applied in the field of RFID detection channel in warehousing logistics management, can solve the problems of inventory detection data confusion, difficulty in ensuring accuracy, and low work efficiency, so as to prevent information cross-reading accidents, protect internal structures, The effect of increasing the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

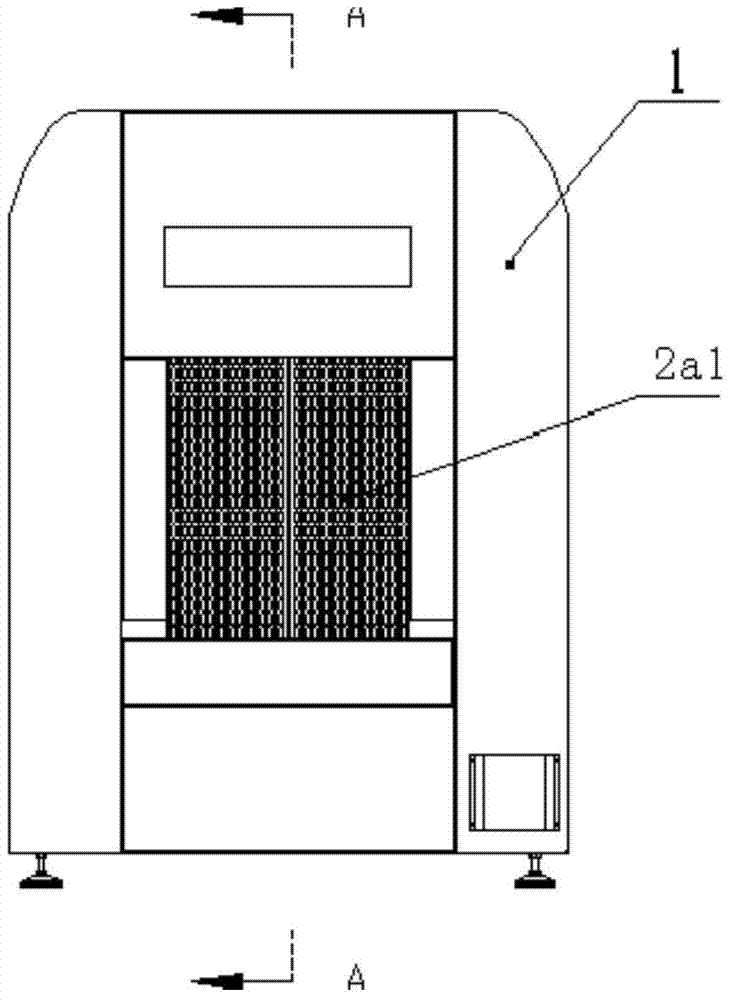

[0021] Example 1: Combination structure of side door and box frame, see Figure 4 and zoom in Figure 6 , the inner layer shielding structure door frame position is that the accessory metal plate is continuously bent at right angles and reversely bent, and its side plane is welded parallel to the frame, so that it is fixed on the frame and becomes a groove for receiving automatic side-by-side doors 2a1, 2a2. The door frame of the outer shielding structure: the metal plate is continuously folded at right angles and reversed to form a bent veneer 12, and then welded with the plane of one side and the edge of the door and embedded in the door frame of the outer shielding structure.

example 2

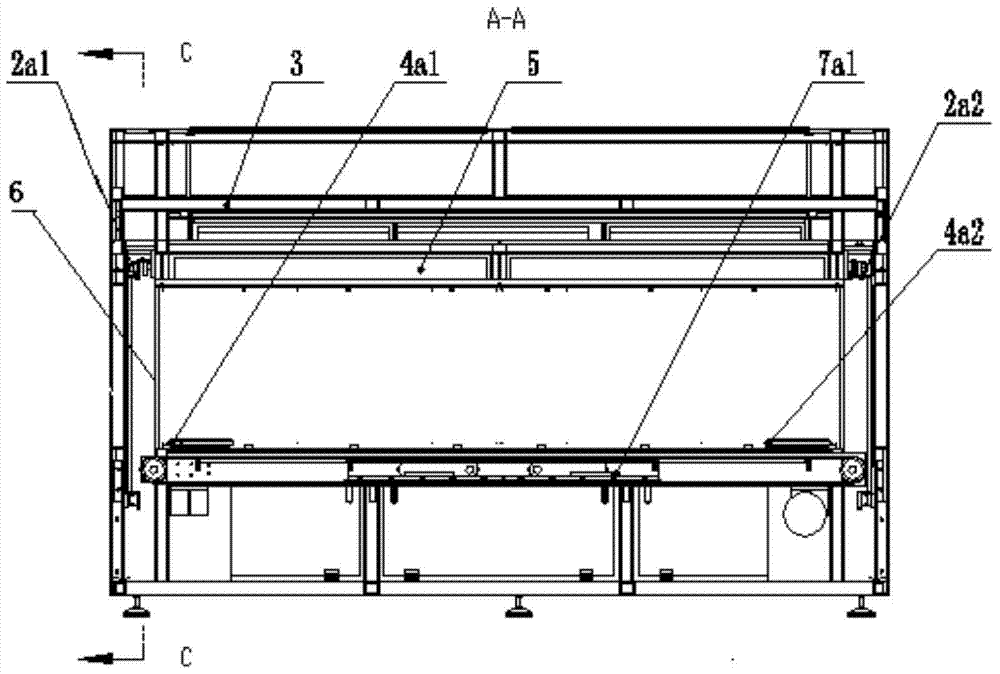

[0022] Example 2: Double screen door with upper lift cover and inner roller shutter:

[0023] The box set in the detection channel is opened with a flip-up cover, and the metal frame 3 is covered with iron sheets on both sides as described above, and the edges are all Figure 6 As shown in the bending covering, the width of the upper cover should cover the upper opening and the surrounding gaps; lift the inner opening of the box, set two parallel tracks, and set the reel at one end perpendicular to the two tracks, the roller shutter is a metal mesh, The reel motor switch is connected to the pivot of the upper flip cover. Antennas / electrical devices are arranged between the covering layers of each surface of the box body, and are electrically connected with the detection and reading device.

example 3

[0024] Example 3: The outer shielding layer is bent and covered with an iron plate, and combined with the frame according to the above-mentioned edge bending. For the gap where the joint space of the above-mentioned frame structure is smaller than the thickness of the bent laminate 12, use tin foil foam tape to stick to the gap between the two joints. The tin foil conducts electricity and also blocks electrical signals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com