Mold release film and method for manufacturing semiconductor package

A release film, semi-conductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problem of destroying semiconductor components, etc., and achieve excellent anti-static effect and excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

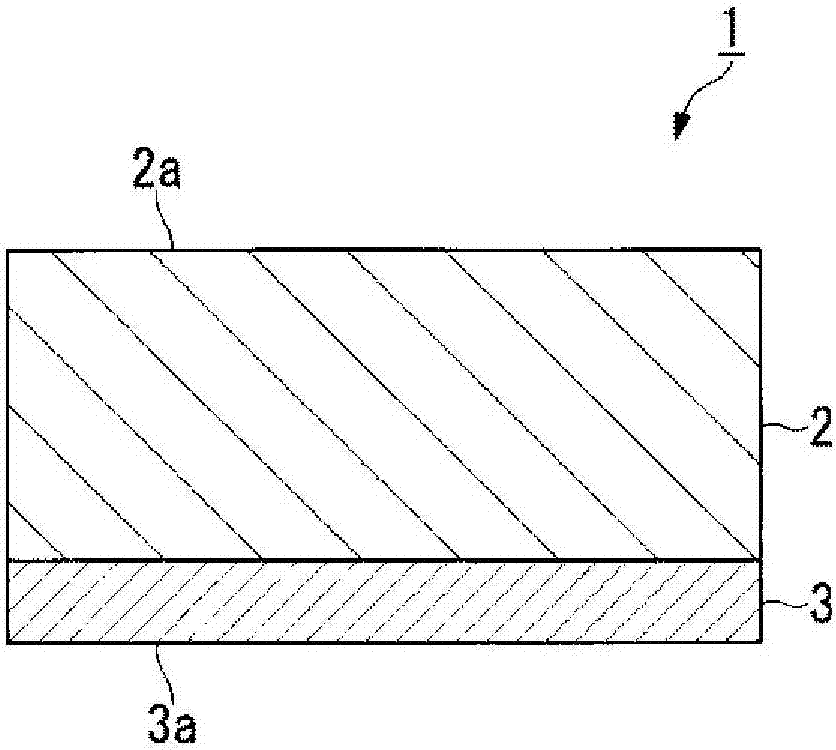

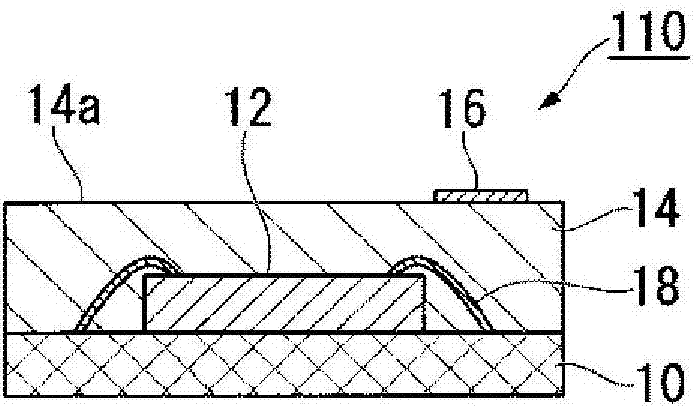

[0224] use Figure 5-7 The first embodiment of the manufacturing method of the semiconductor package of the present invention will be described. In this embodiment, the release film 1 is used as the release film and manufactured by compression molding. image 3 An example of a semiconductor package 110 is shown.

[0225] The manufacturing method of the semiconductor package according to this embodiment includes the following steps (α1) to (α7).

[0226] (α1) The mold release film 1 is arranged in a mold having a fixed upper mold 20, a cavity bottom surface member 22, and a frame-shaped movable lower mold 24 arranged around the periphery of the cavity bottom surface member 22, and the mold release film 1 covers all Describe the cavity 26 of the mould, and the surface 2a of the releasable substrate 2 side of the release film 1 faces the space in the cavity 26 (making the surface 3a on the antistatic layer 3 side contact the cavity surface of the mould) ( Figure 5 ).

[0227...

no. 2 Embodiment approach

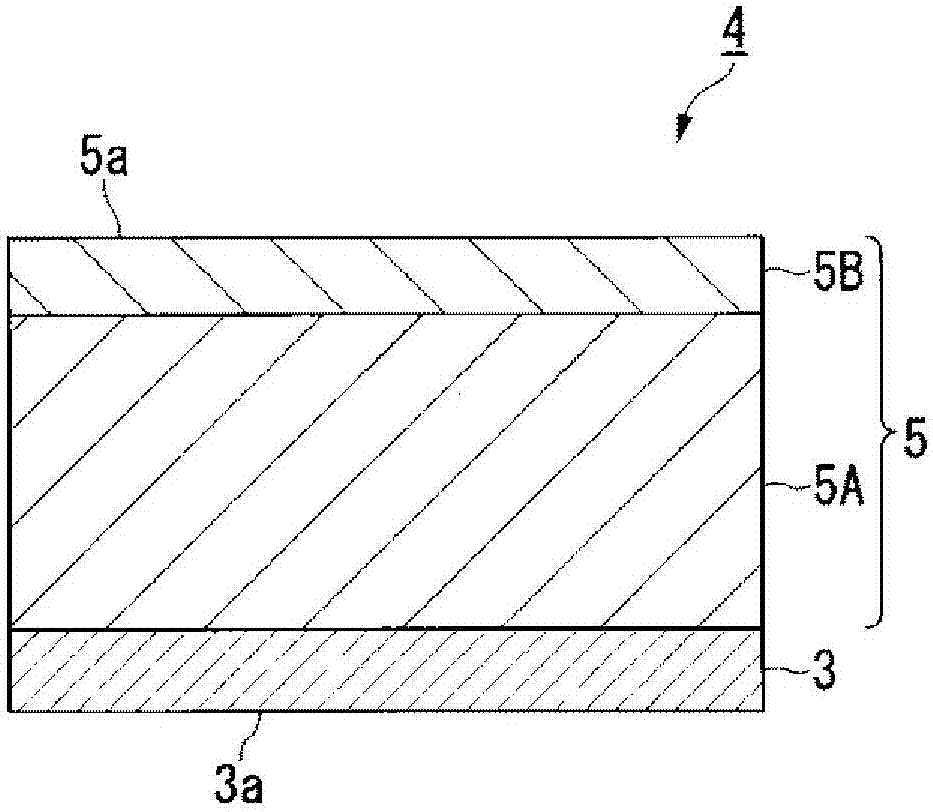

[0234] use Figure 8-11 A second embodiment of the manufacturing method of the semiconductor package of the present invention will be described. In this embodiment, the release film 1 is used as the release film and manufactured by transfer molding. Figure 4 An example of a semiconductor package 120 is shown.

[0235] The manufacturing method of the semiconductor package according to this embodiment includes the following steps (β1) to (β5).

[0236] (β1) The release film 1 is arranged so that the release film 1 covers the cavity 54 of the upper die 50 of the mold having the upper die 50 and the lower die 52 and the surface 2a of the release film 1 on the release base 2 side faces Space in the cavity 54 (making the surface 3a on the antistatic layer 3 side contact with the cavity surface 56 of the upper mold 50) ( Figure 8 ).

[0237] (β2) The process of vacuum-adsorbing the release film 1 on the cavity surface 56 side of the upper mold 50 ( Figure 9 ).

[0238] (β3) ...

Embodiment

[0250] Examples are shown below to describe the present invention in detail. However, the present invention is not limited to the following description.

[0251] Among Examples 1 to 18 described later, Examples 1 to 13 are examples, and Examples 14 to 18 are comparative examples.

[0252] The evaluation methods and materials used in each example are shown below.

[0253] 〔Evaluation method〕

[0254] (thickness)

[0255] The thickness (μm) of the substrate was measured in accordance with ISO 4591:1992 (method B1 of JIS K7130:1999, measuring method of thickness of a sample collected from a plastic film or sheet by mass method).

[0256] The thickness (nm) of the antistatic layer was measured with a transmission type infrared film thickness meter RX-100 (manufactured by Kurabo Industries, Ltd. (Kurabo Industries, Ltd.)).

[0257] (arithmetic mean roughness Ra)

[0258] The arithmetic mean roughness Ra (μm) of the surface was measured in accordance with JIS B 0601:2013 (ISO 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com