Rapid assembling and disassembling combination fixture for removing burrs on inner walls of slender rods through ultrasonic compositing of abrasive flows

A combination fixture and slender rod technology, applied in the direction of grinding workpiece support, etc., can solve the problems of inconvenient clamping and low efficiency, and achieve the effect of convenient clamping and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

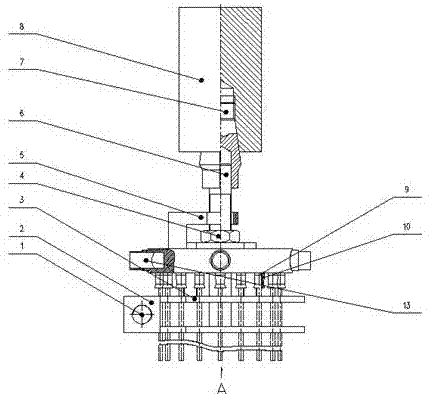

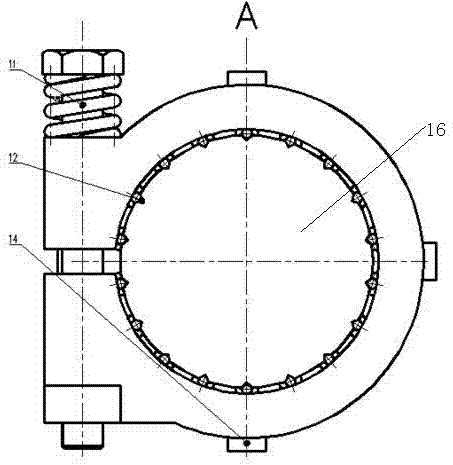

[0023] Such as Figure 1-3 shown.

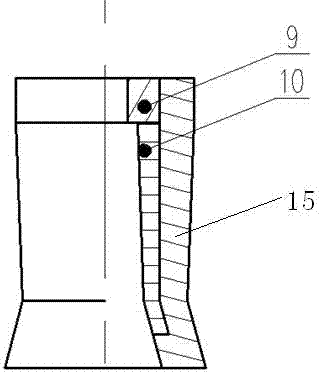

[0024] A quick-installation and quick-disassembly combined fixture for abrasive flow ultrasonic compound removal of burrs on the inner wall of a slender rod, which includes: a fixture upper body 5, a fixture lower body 6, a tool head connector 7 and an ultrasonic vibration tool head 8, such as figure 1 As shown, the ultrasonic vibration tool head 8 is connected to the upper end of the lower main body 6 of the clamp through the tool head connector 7, the ultrasonic vibration tool head 8 is connected to the tool head connector 7 through threads, and the extension of the lower main body 6 of the clamp The upper end of the cylinder is placed in the inner hole of the tool head connector 7, the slope of the tool head connector 7 is greater than the inclination of the inner hole at the lower end of the ultrasonic vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com