Environmental-friendly plastic granulator filter screen processing equipment

A technology of processing equipment and granulator, which is applied in the field of environmentally friendly plastic granulator filter screen processing equipment, can solve the problems of inability to meet the needs of plastic recycling, affecting the smooth progress of filtration, and low efficiency of manual removal, and achieves ideal removal effect. , The effect of low labor intensity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The environmental-friendly plastic granulator filter screen processing equipment of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

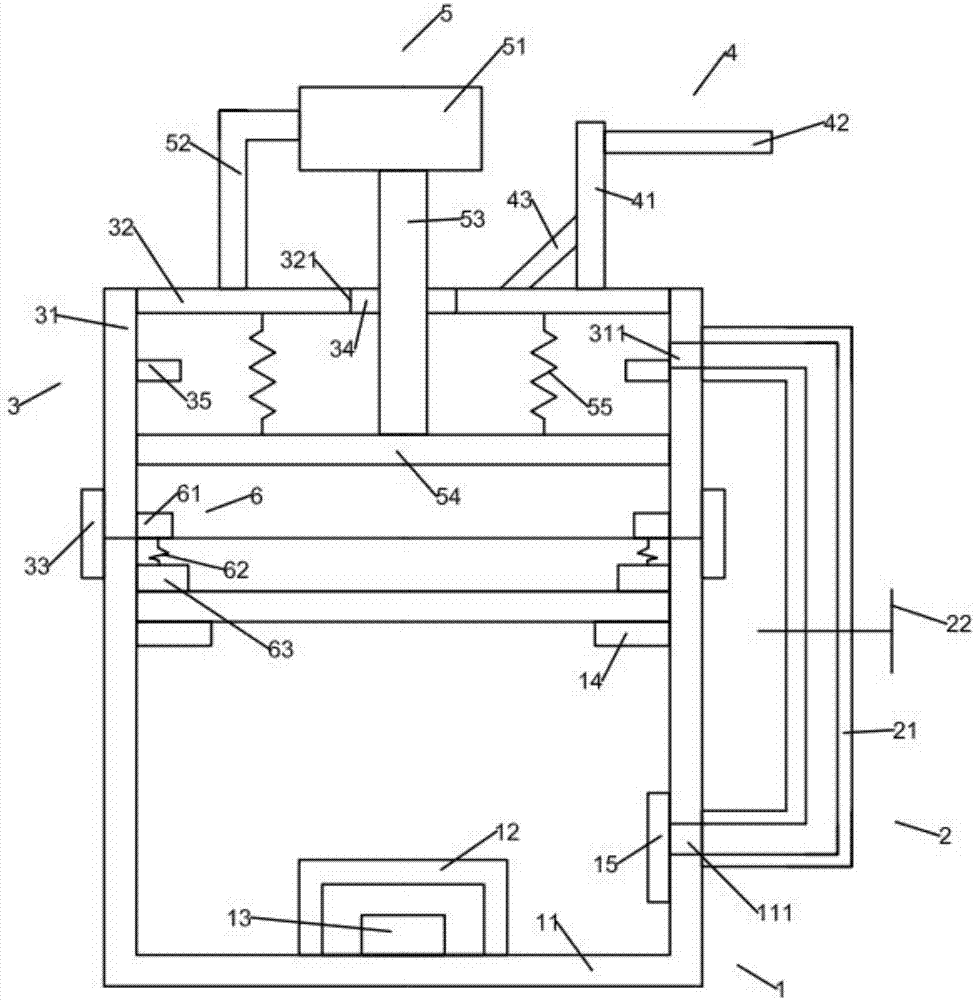

[0016] like figure 1 As shown, the environmentally friendly plastic granulator filter screen processing equipment of the present invention includes a first housing device 1, a pipeline device 2 located on the right side of the first housing device 1, and a pipe device 2 located above the first housing device 1. The second housing device 3, the holding device 4 positioned above the second housing device 3, the piston device 5 arranged on the second housing device 3, and the piston device 5 arranged in the second housing device 3 The abutting device 6 on the left and right sides.

[0017] like figure 1 As shown, the first casing device 1 includes a first casing 11, a heat dissipation frame 12 accommodated in the first casing 11, a heating rod 13 accommodated in the heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com