Method for producing a shim with an adjustable thickness, which can withstand high temperatures, and said shim

A technology of pads, manufacturing methods, applied in the directions of non-polymer adhesive additives, adhesive types, polyurea/polyurethane adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

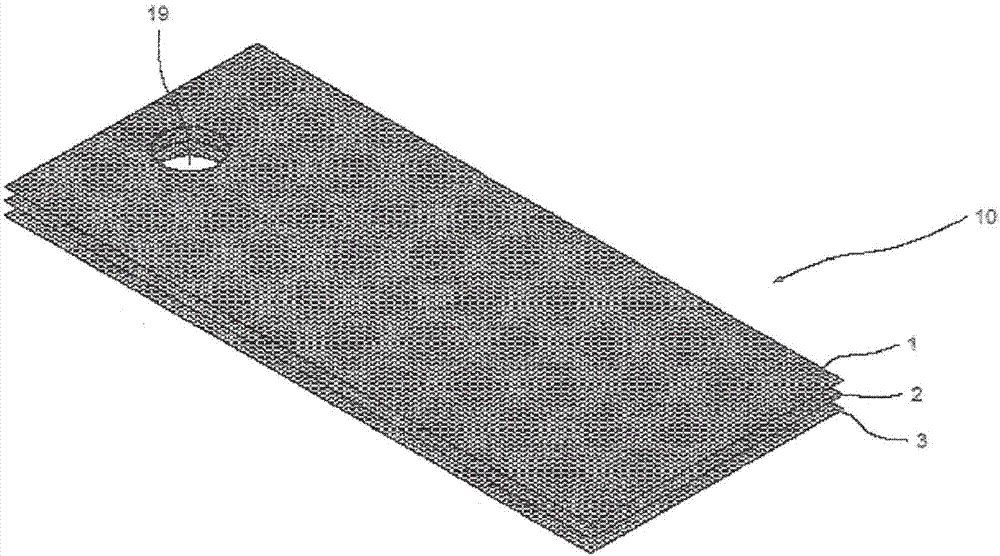

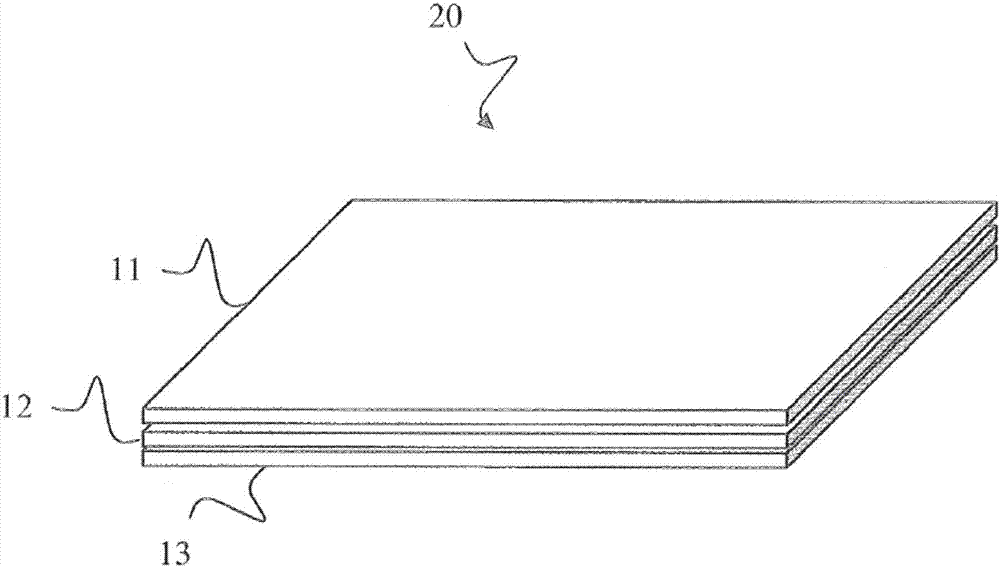

[0037] figure 1 A layered product is shown, more precisely a thickness block 10 consisting of a stack of sheets 1, 2, 3 of fibrous material. figure 2 A layered product is shown, more precisely a thickness block 20 consisting of a stack of metal sheets 11 , 12 , 13 . The method which will now be described in its various variants makes possible a layered product which can be used as desired, for example, for cutting into a shape suitable for its application, such as a drill with a precision comparable to that obtained in metals. Hole 19 is shown.

[0038] The process to be described also leads to layered products having high thermomechanical strength, in other words products which retain good mechanical properties when subjected to high temperatures, including in the presence of severe impacts.

[0039] That is to say, the layered product can be used as a thickness block until it may exceed 200°C and reach 280°C, 370°C, 380°C, or even 400°C or higher, at least and preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com