Full-automatic material piling operation method

A fully automatic, stacking technology, applied in the direction of transportation and packaging, loading/unloading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

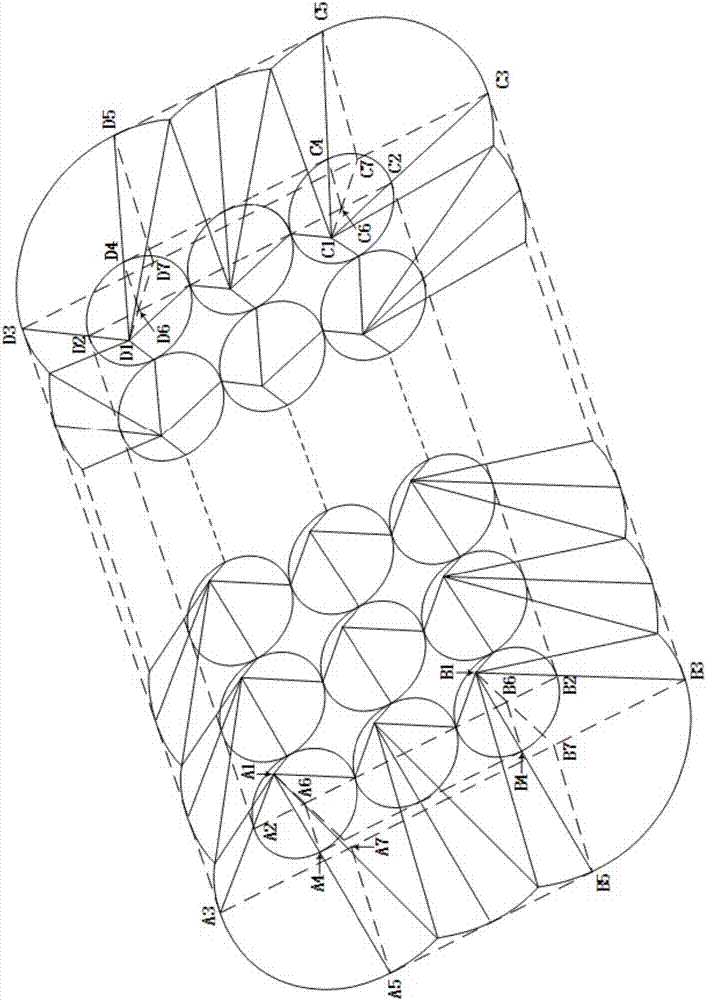

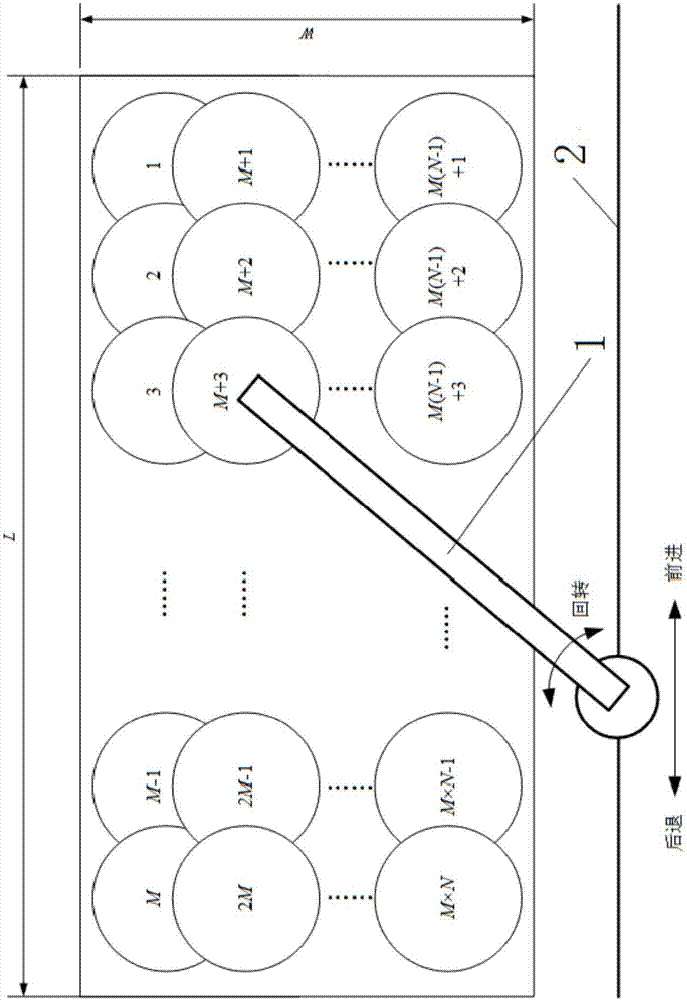

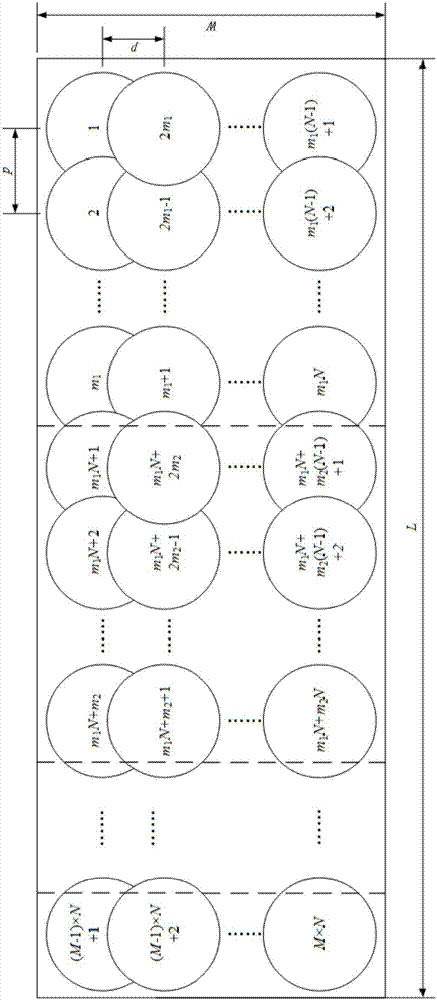

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The present invention proposes a new fully automatic stacking operation method, the core principle of which is:

[0028] 1. In the designated operation area, according to the operation plan parameters, calculate the length of the stockpile, divide the operation area into several blocks, and use a single row of vertical stacking in the last block, so that a regular rectangular stockpile is formed at the end of the operation; through rotation and The linkage of the cart realizes the switching between blocks, avoiding collision with the stockpile, and also avoiding the stockpile from exceeding the boundary.

[0029] 2. The method of walking fixed-point stacking is adopted in each block, and the design of the operation point and operation path is based on following the safety rules, reducing the large-scale movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com