Arc-shaped spray dyeing device

A kind of equipment and arc-shaped technology, applied in the direction of spraying/jetting textile material processing, processing textile material carriers, etc., can solve the problems of uneven spray dyeing, difficulty in keeping the cloth flat, and color difference between the front and back sides, so as to improve the penetration effect and ensure the removal of The effect of maintaining the wrinkle effect and improving the absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

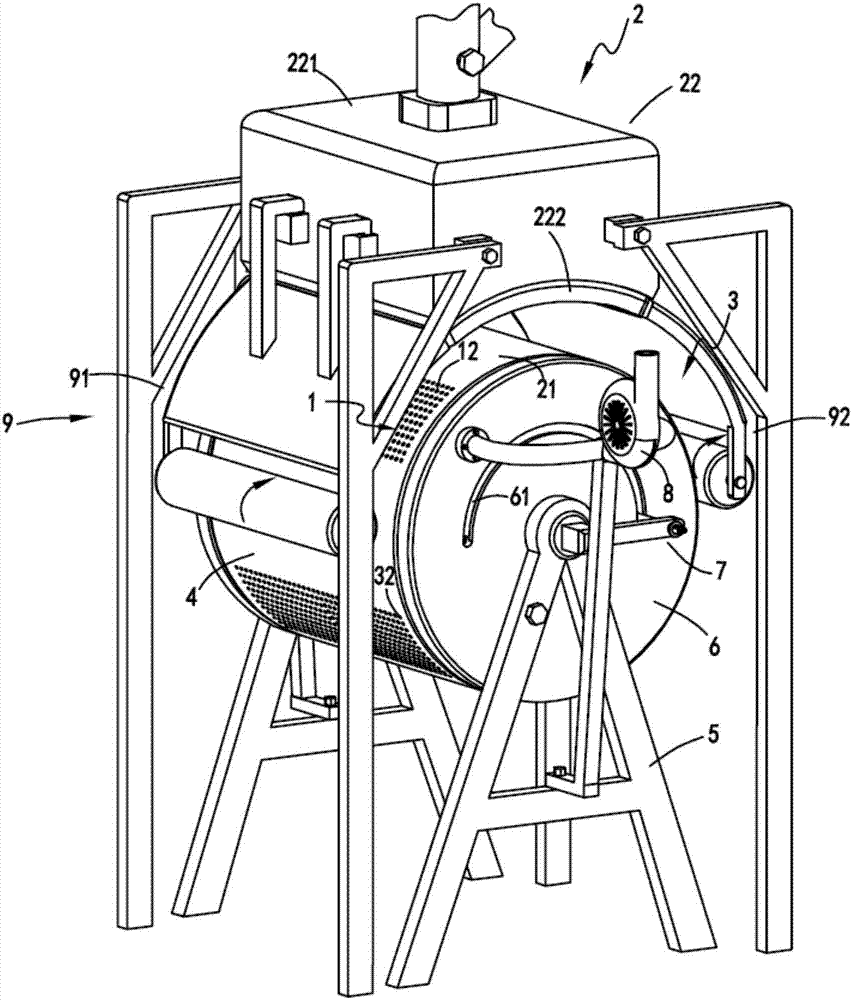

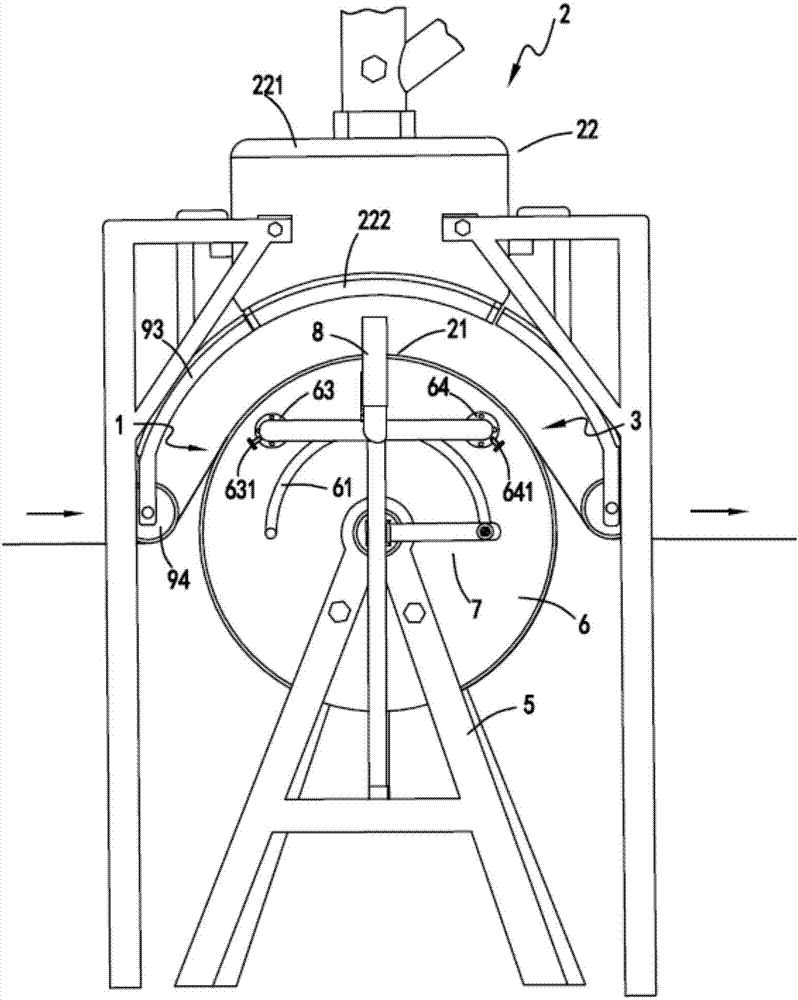

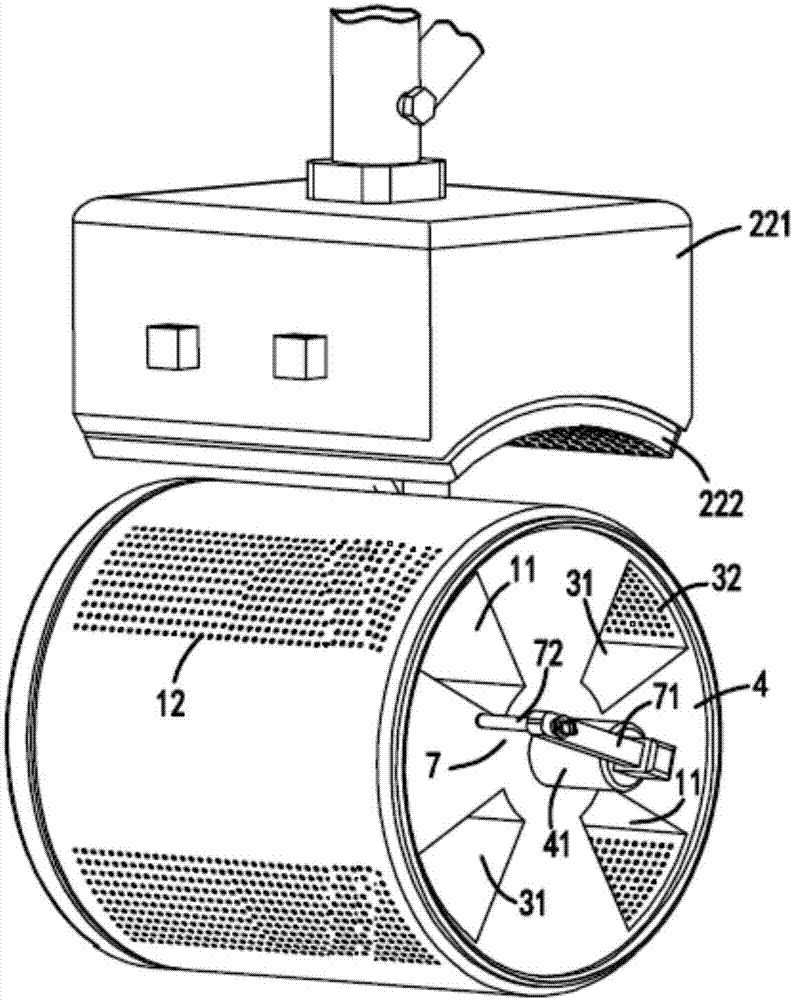

[0037] figure 1 It is a schematic diagram of the structure of the arc-shaped spraying equipment, figure 2 It is a schematic diagram of the front view of the arc-shaped spraying equipment, image 3 It is a schematic diagram of the structure of the spraying mechanism and the roller, Figure 4 It is a schematic diagram of the structure of the sealing cover and the transposition device, Figure 5 is a partial cutaway diagram of the roller, Figure 6 It is a schematic diagram of the enlarged cross-section of the smoothing hole, Figure 7 Schematic diagram of the transposition device. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, an arc-shaped spraying equipment includes a smoothing part 1, which is used to absorb and smooth the cloth to be sprayed; a spraying part 2, and the spraying part 2 is set At the rear end of the smoothing part 1, the spraying and dyeing part 2 includes a supporting area 21 for supporting the c...

Embodiment 2

[0049] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the sealing cover 6 is also provided with a suction port a63 and a suction port b64, and the suction port a63 and the suction port b64 respectively correspond to when they are in the working position. The negative pressure chamber a11 and the negative pressure chamber b31, the suction port a63 and the suction port b64 are connected to the same suction device 8 through pipelines; the suction port a63 is provided with a device for controlling the pressure in the negative pressure chamber a11 A pressure regulating valve a631, the suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com