Non-woven fabric hot-pressing equipment

A technology of hot pressing equipment and non-woven fabrics, which is applied in the direction of textiles and papermaking, fabric surface trimming, etc., which can solve the problems of non-woven fabric damage, low strength of non-woven fabrics, and excessive hot pressing of non-wrinkled parts, so as to avoid The effect of damaged non-woven fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

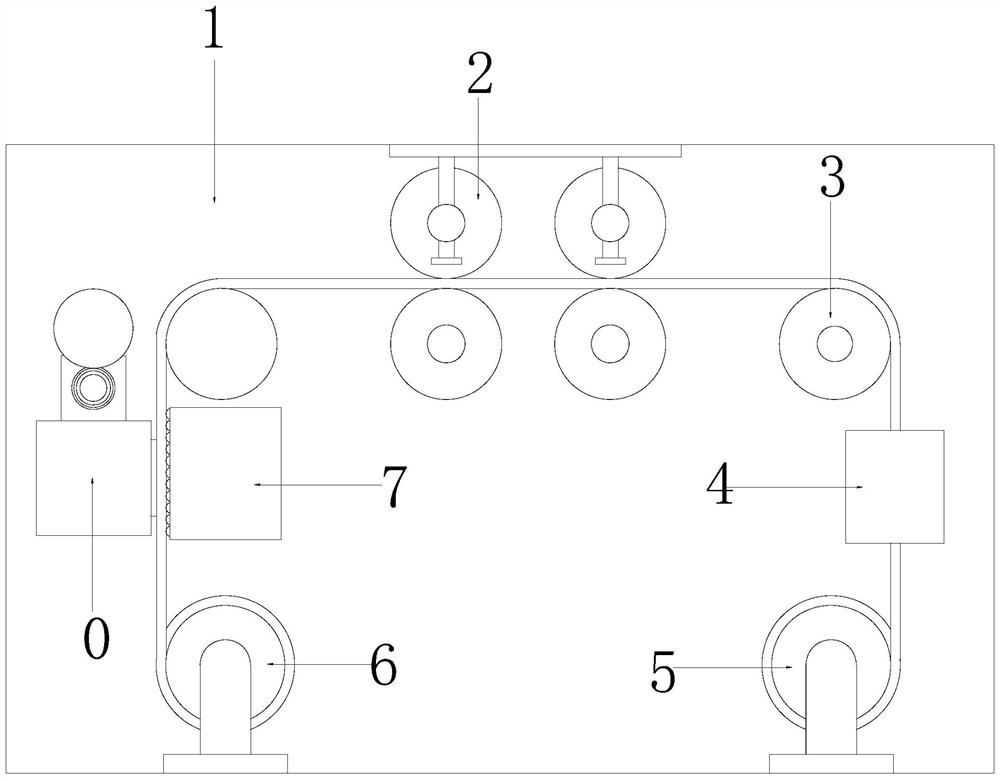

[0033] see Figure 1-4 , the present invention provides a technical solution for non-woven fabric hot-pressing equipment: its structure includes a local wrinkle-removing hot-pressing device 0, a body 1, a lift-type hot-pressing roller device 2, a guide roller 3, a cooling device 4, and a non-woven fabric winding Device 5, non-woven fabric release device 6, support auxiliary wrinkle removal device 7, the body 1 is provided with a non-woven fabric winding device 5, a non-woven fabric release device 6, and the top of the non-woven fabric release device 6 is provided with Support auxiliary wrinkle removal device 7, cooling device 4 is provided above the non-woven fabric winding device 5, guide roller 3 connected to body 1 is provided above the cooling device 4 and support auxiliary wrinkle removal device 7, Described guide roller 3 is provided with two, and between two described guide rollers 3 is provided with the lifting type hot pressing roller device 2 that is connected with b...

Embodiment 2

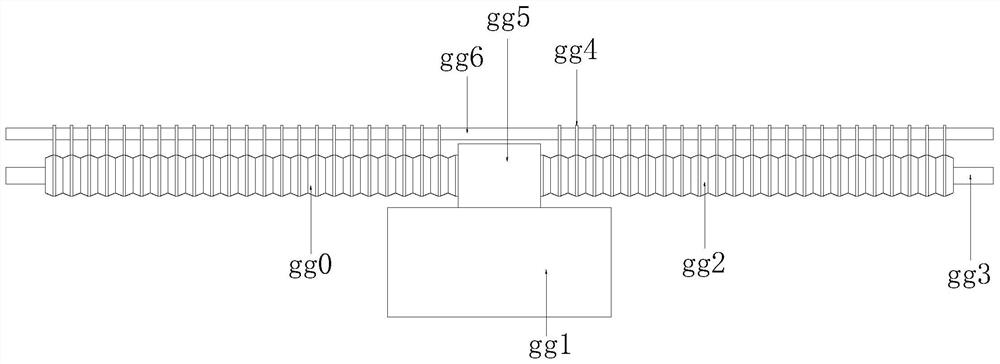

[0044] Please refer to 5, the wrinkle removal device gg1 includes a wind deflector 111, a non-intermittent air guide assembly 222, a casing 333, and a heat-pressing smoothing roller 444, and the non-intermittent air guide assembly 222 is arranged inside the casing 333. One side of the non-intermittent air guide assembly 222 is provided with an air deflector 111, and the other side is provided with a hot-press smoothing roller 444, and two or more of the hot-press smoothing rollers 444 are provided. 444 is in contact with the nonwoven.

[0045] The setting of the above-mentioned heat-press smoothing roller 444 is to longitudinally heat-press the partially creped non-woven fabric.

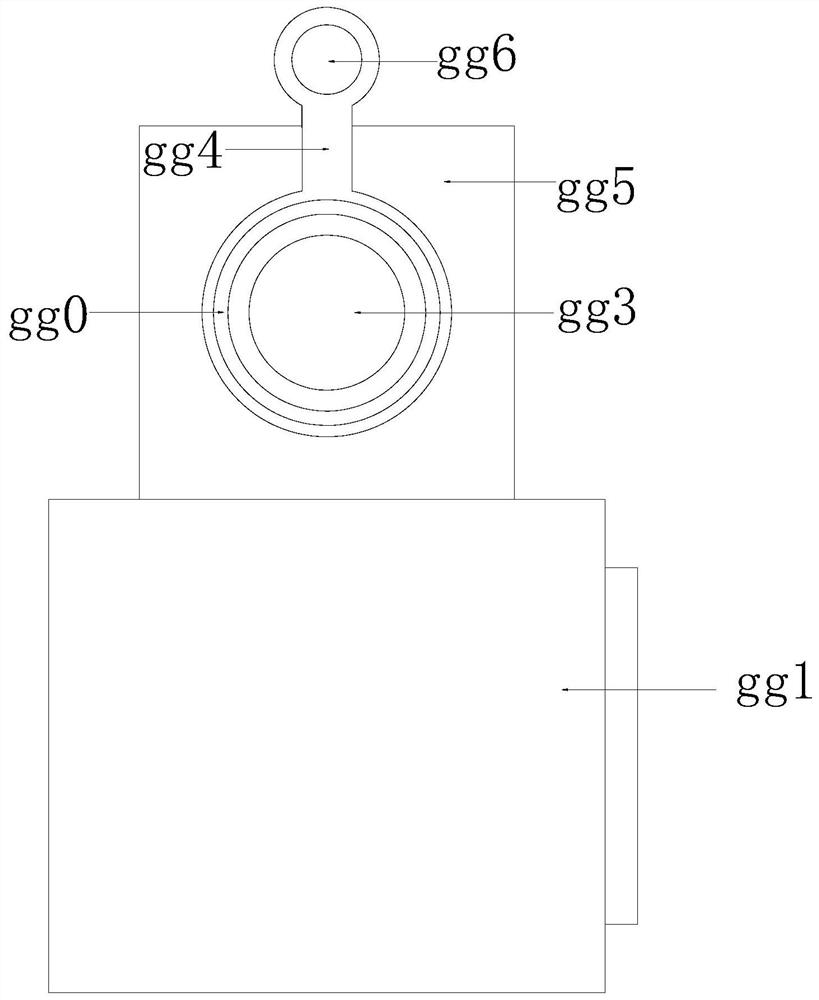

[0046] Please refer to 6. The non-intermittent air guide assembly 222 includes a transmission group R1, a micro-motor R2, an annular disk R3, a driving gear R4, a large arc rod R5, a piston block R6, and an air outlet pipe R7. The top surface of the annular disk R3 and the bottom surface are fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com