crts type I ballastless track retest rail transport vehicle

A technology of rail transport vehicle and ballastless track, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of bruising, labor consumption, labor consumption, physical strength, etc., achieve strong reproducibility, improve efficiency, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

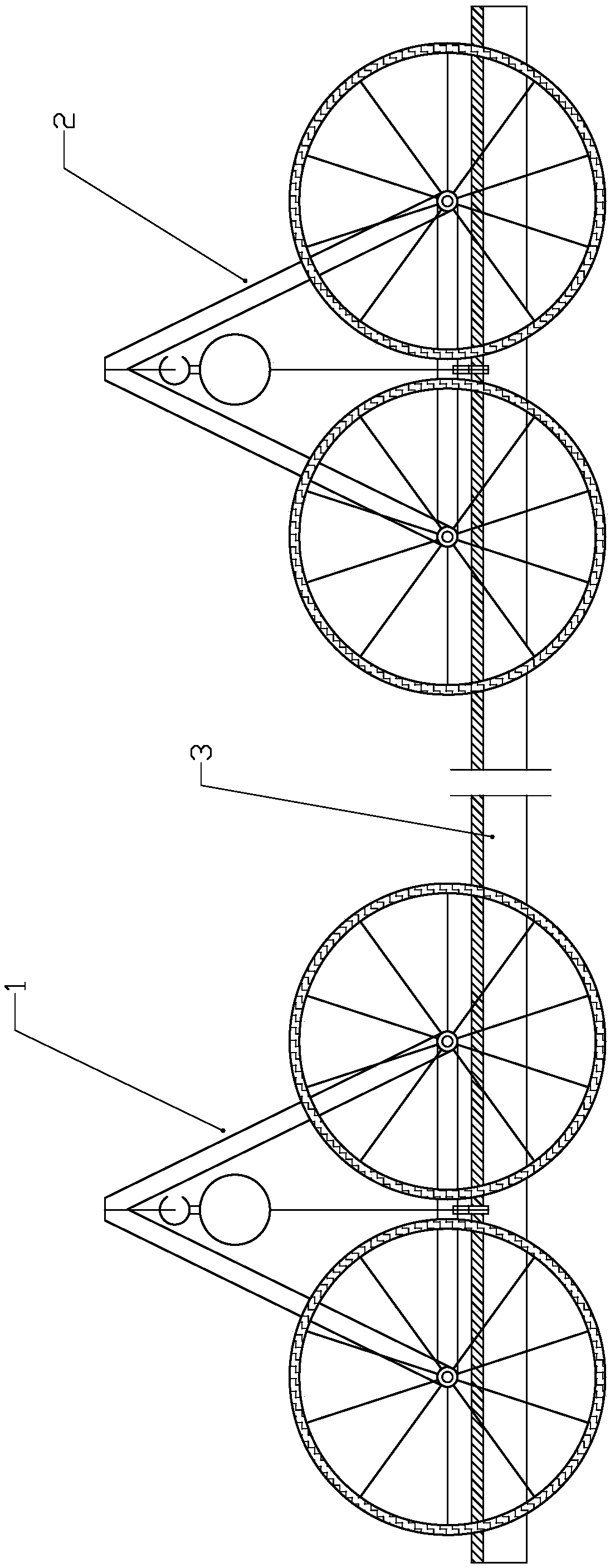

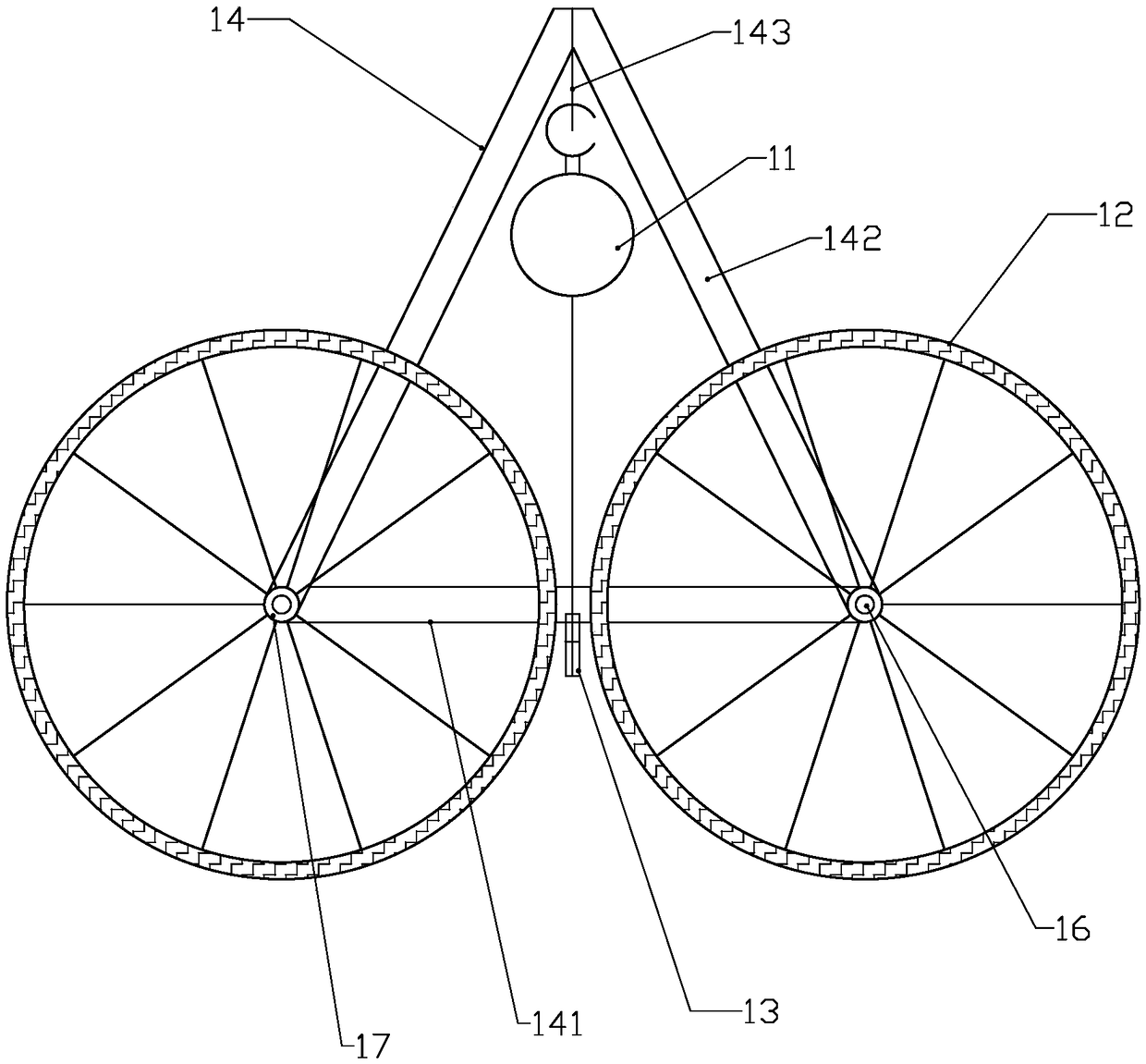

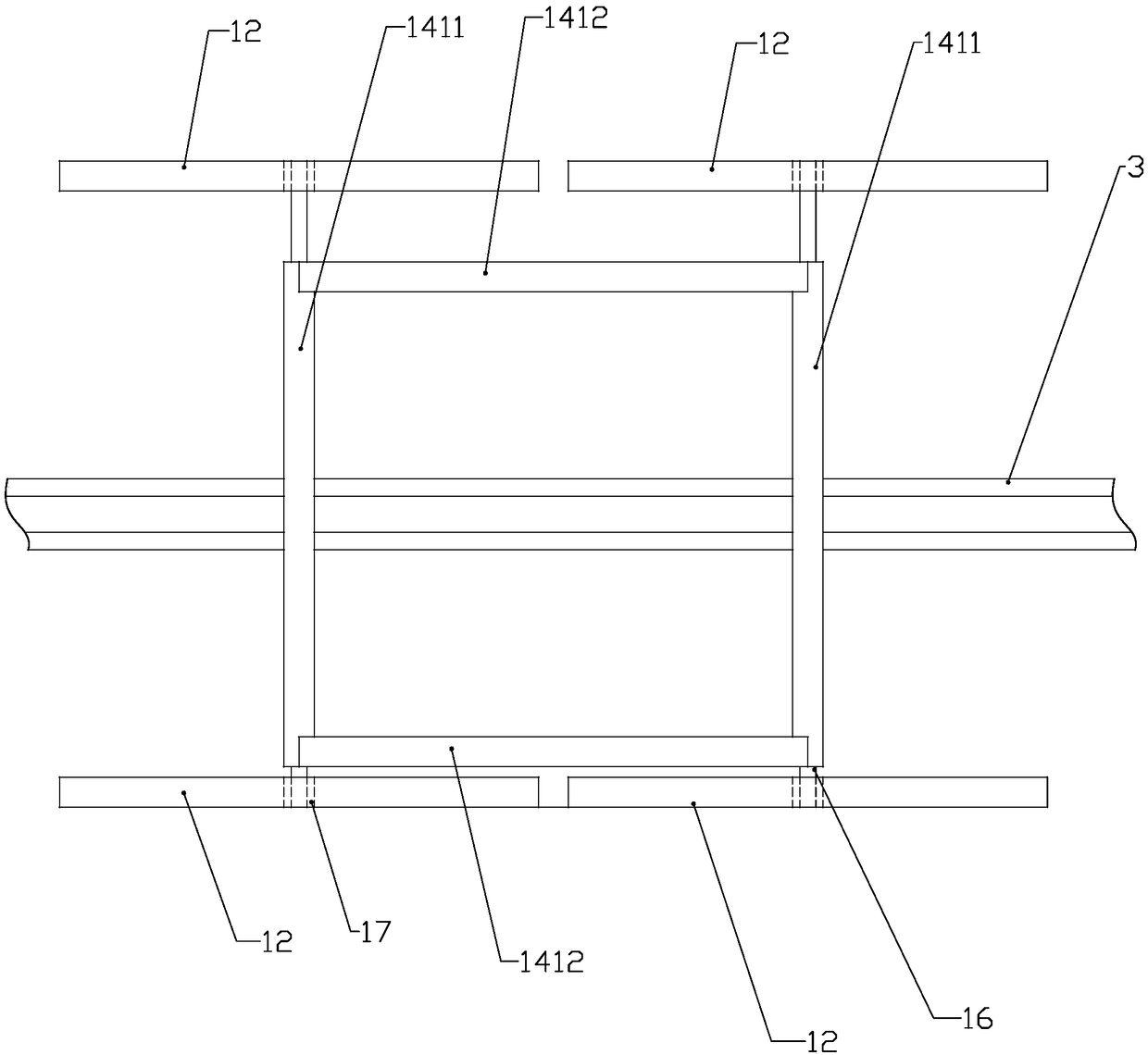

[0019] Refer to the attached figure 1 to attach Figure 5 The CRTS I type ballastless track retesting rail transport vehicle of the present invention is described in detail below.

[0020] The CRTS I type ballastless track retesting rail transport vehicle of the present invention has a structure comprising a front transport vehicle body 1 and a rear transport vehicle body 2, and the front transport vehicle body 1 and the rear transport vehicle body 2 are respectively Including chain hoists 11, wheels 12, rail grabbing hooks 13, support frames 14 and connecting ropes 15, the wheels 12 include four, which are symmetrically arranged on the left and right sides of the rail 3 in pairs, and between the left and right symmetrical wheels 12 Axles 16 are arranged between them, and bearings 17 are arranged between the axles 16 and the wheels 12. A support frame 14 is arranged on the top of the two axles 16, and a chain hoist 11 is arranged on the top of the support frame 14. The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com