Lifting vehicle body, wheels and crawler belt combined type stair climbing vehicle

A crawler composite, crawler-type technology, applied in the direction of trolleys, motor vehicles, trolley accessories, etc., to prevent overturning, ensure safety, and increase the lifting height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

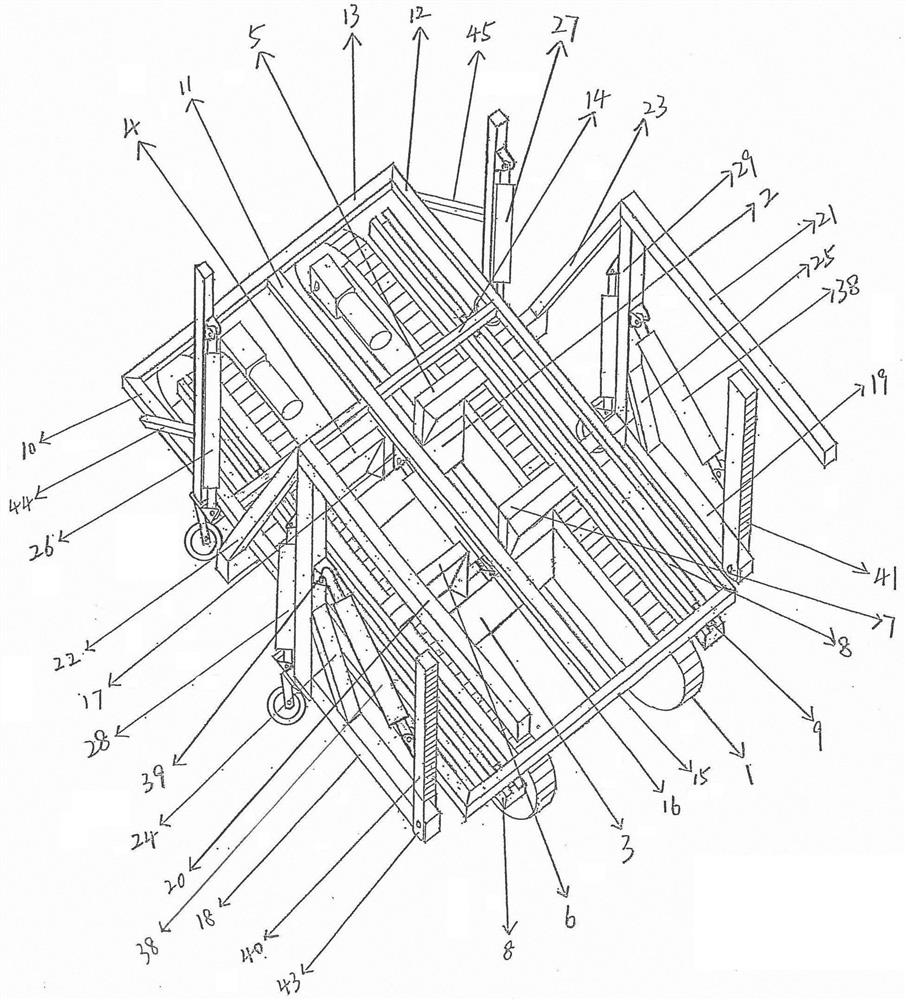

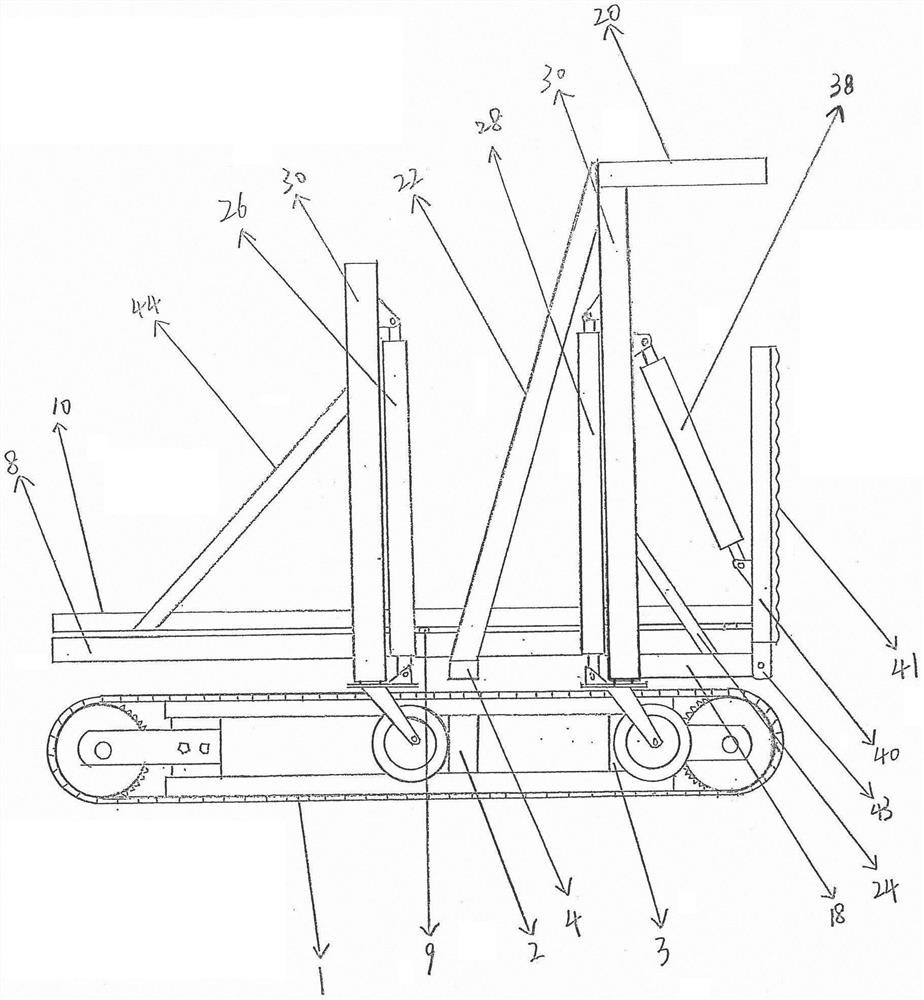

[0026]Embodiment 1: Two-stage four-point car body (commonly known as: heavy-duty)

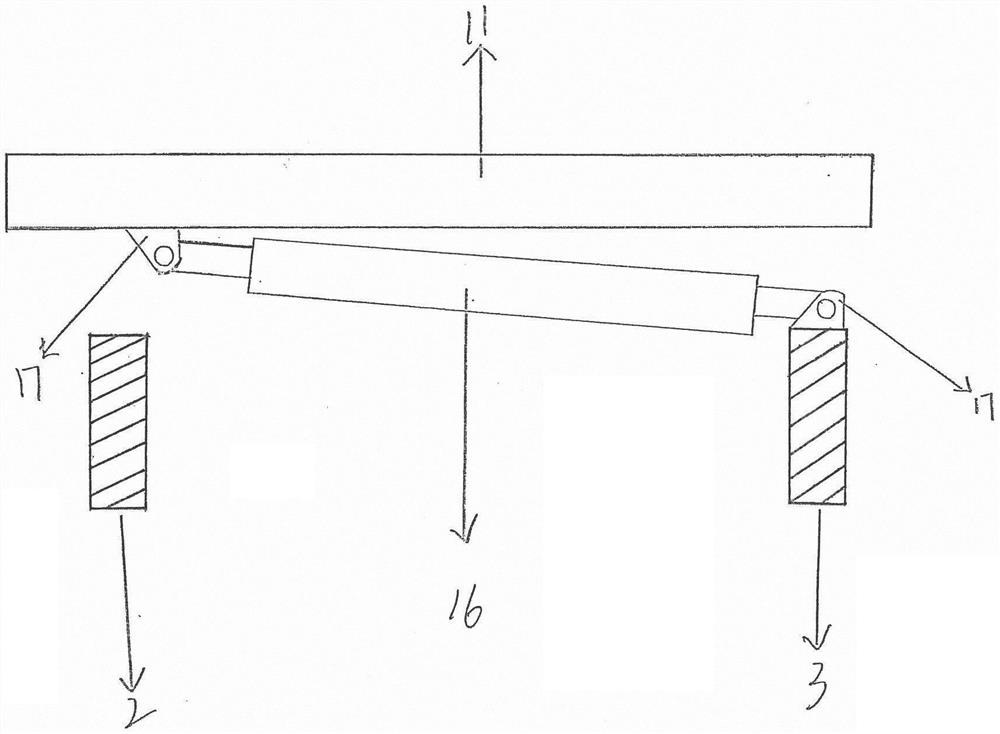

[0027] Its implementation is as follows: figure 1 As shown, the left front connecting frame (4) and the right front connecting frame (5) are respectively welded on the left and right sides of the front base beam (2), and the left rear connecting frame (6) and the right rear connecting frame are respectively welded on the left and right sides of the rear base beam (3). frame (7), the four connecting frames need to be higher than the upper surface of the track (such as figure 2 shown), and extend a certain distance to the left and right sides. Weld a "C" shaped track (8) on the left front connecting frame (4) and the left rear connecting frame (6) (such as figure 2 As shown), another "C" shaped track is welded on the right front connecting frame (5) and the right rear connecting frame (7), and the two "C" shaped tracks (8) are kept at an appropriate distance, and are connected to the car body...

Embodiment 2

[0031] Embodiment 2: Two-stage three-point car body (commonly known as: medium-sized)

[0032] Its implementation method is: in embodiment 2, only the structure of the armrest system and the position of the rear stage lifting system are different from embodiment 1, and the implementation methods of other systems are the same, and will not be described in detail here.

[0033] Such as Figure 9 As shown, the front end of the left longitudinal frame (50) is welded with the left front connecting frame (4), the middle part is welded with the left rear connecting frame (6), the rear end is welded with the left vertical frame (52), and the left reinforcing bracket (51) is respectively Be welded on the left longitudinal frame (50) and the left vertical frame (52), to strengthen its structural strength, the implementation mode of the right part is identical with the left side; ) and the top of the right vertical frame (55) are welded, the rear stage lifting system (59) is arranged in...

Embodiment 3

[0034] Embodiment 3: One-level two-point car body (commonly known as: light)

[0035] Its implementation is as follows: Figure 10 As shown, weld the left front connecting frame (4) and the right front connecting frame (5) on the front base beam (2), weld the left rear connecting bracket (6) and the right rear connecting bracket (7) on the rear base beam (3) , a lower cross frame (71) is welded on the left front connecting frame (4) and the right front connecting frame (5), and a lower horizontal frame is also welded on the left rear connecting bracket (6) and the right rear connecting bracket (7) (71), weld two lower longitudinal frames (70) respectively at the two ends of these two lower horizontal frames (71), and weld two lower horizontal frames ( 71), forming a shelf. Three vertical frames (72) are respectively welded at the welds of the lower vertical frame (70) on the left side and the three lower horizontal frames (71) at the rear, and an upper vertical frame (75) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com