Pipelined water heating heater

A heater and pipeline technology, applied in the field of heating, can solve the problems of long preheating time, difficulty in timely heating supply, and space occupied by the water tank.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

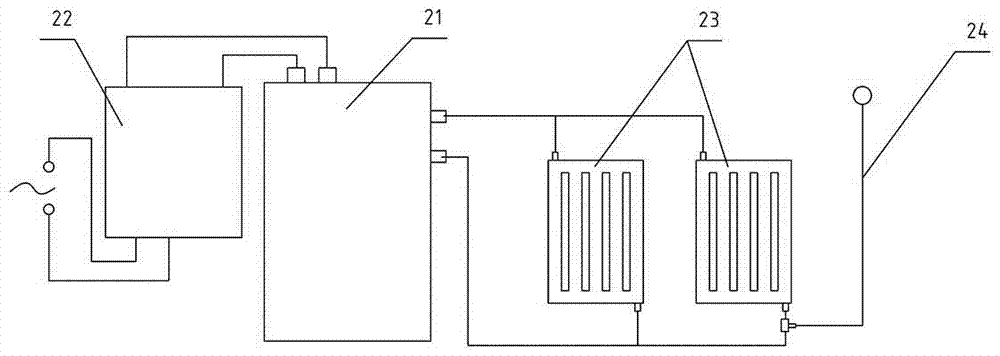

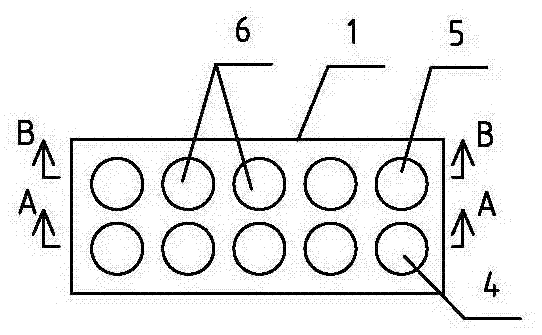

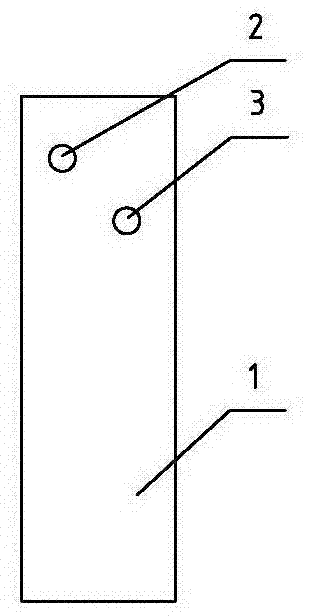

[0016] like figure 1 As shown, the pipeline water heating heater of the present invention includes an electric heating module 21 , a control circuit 22 and a radiator 23 . like figure 2 — Figure 5 As shown, the electric heating module 21 includes a module body 1 with a rectangular block structure and an electric heating pipe 7 mounted on the module body 1. The module body 1 is integrally cast with cast iron or cast aluminum and cast copper materials with good thermal conductivity. After molding, the module body 1 is an integrated monolithic structure. The side wall of the module body 1 is provided with a water inlet 2 and a water outlet 3. The module body 1 is provided with a plurality of longitudinally arranged blind holes. The blind holes extend straight down from the upper surface of the module body 1. The blind holes are arranged in a single row and are equidistantly distributed, the water inlet 2 is opened on the outer wall of the first blind hole 4 located at the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com