POS machine safety contact pressure test device and test method

A technology of safety contacts and POS machines, applied in the field of testing, can solve the problems of inability to accurately measure the critical pressure value of safety contacts triggering, affecting the preload and tolerance of silicone pads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Please refer to Figure 1-2 , Embodiment 1 of the present invention is:

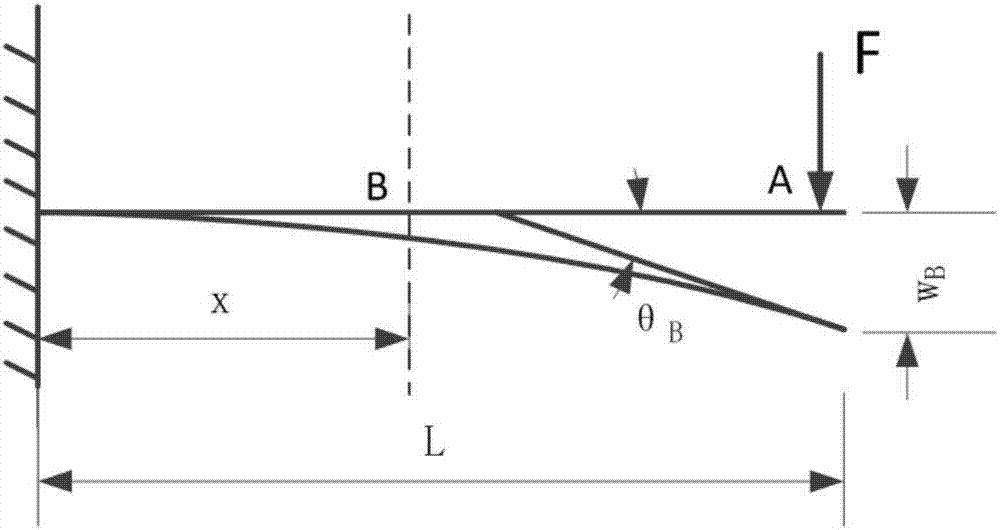

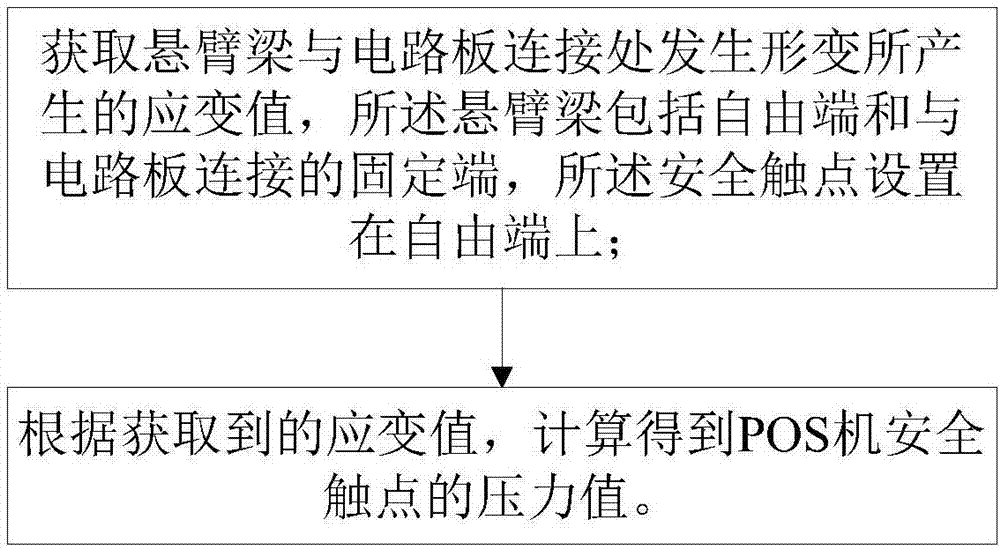

[0042] A POS machine safety contact pressure testing device provided by the present invention includes a circuit board, on which a safety contact is provided, on which a cantilever beam is provided, and the cantilever beam includes a free end and a circuit The fixed end of the board connection, the safety contact is set on the free end, and the fixed end is provided with a strain gauge used to obtain the strain value generated by the deformation of the connection between the cantilever beam and the circuit board, and the strain gauge and the processing The processor is used to calculate the pressure value of the safety contact of the POS machine according to the acquired strain value.

[0043] The cantilever beam is a cantilever beam cut from the original circuit board, the surrounding groove of the cantilever beam is open, and the safety contact is set at the free end of the cantilever arm, whic...

Embodiment 2

[0053] Please refer to Figure 1-2 , the second embodiment of the present invention is:

[0054] On the basis of the first embodiment above, the strain gauge is further limited, specifically: the strain gauge is located in the middle of the safety contact and the end of the fixed end. Setting the strain gauge in the middle of the safety contact and the end of the fixed end can improve the sensitivity of the strain gauge, and then can accurately obtain the strain value generated by the deformation of the connection between the cantilever beam and the circuit board, and calculate the POS based on the strain value The pressure value of the machine safety contact, the pressure value at this time is the most accurate. The strain gauges are wired to the processor. The above-mentioned strain gauges are connected by wires, and the collected strain values are transmitted to the processor (the processor is a peripheral strain tester) by wire, which can improve the transmission effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com