Precise Measuring Device for Conductive Slip Ring Friction Torque

A conductive slip ring and friction torque technology, applied in measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of affecting test results, different data, easy dragging to the ground or table, etc., to achieve accurate measurement , reduce the influence of subjective factors, and broaden the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

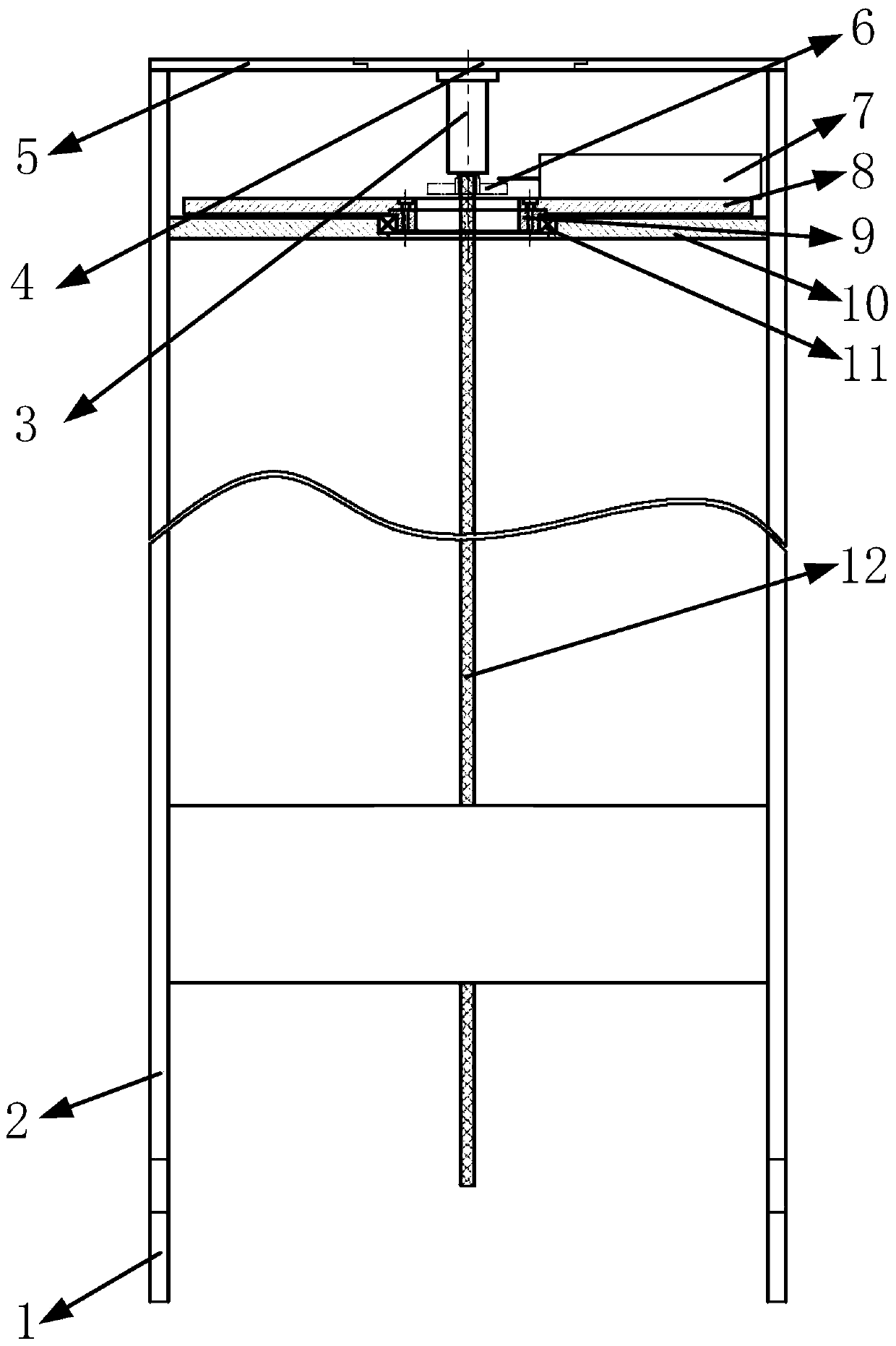

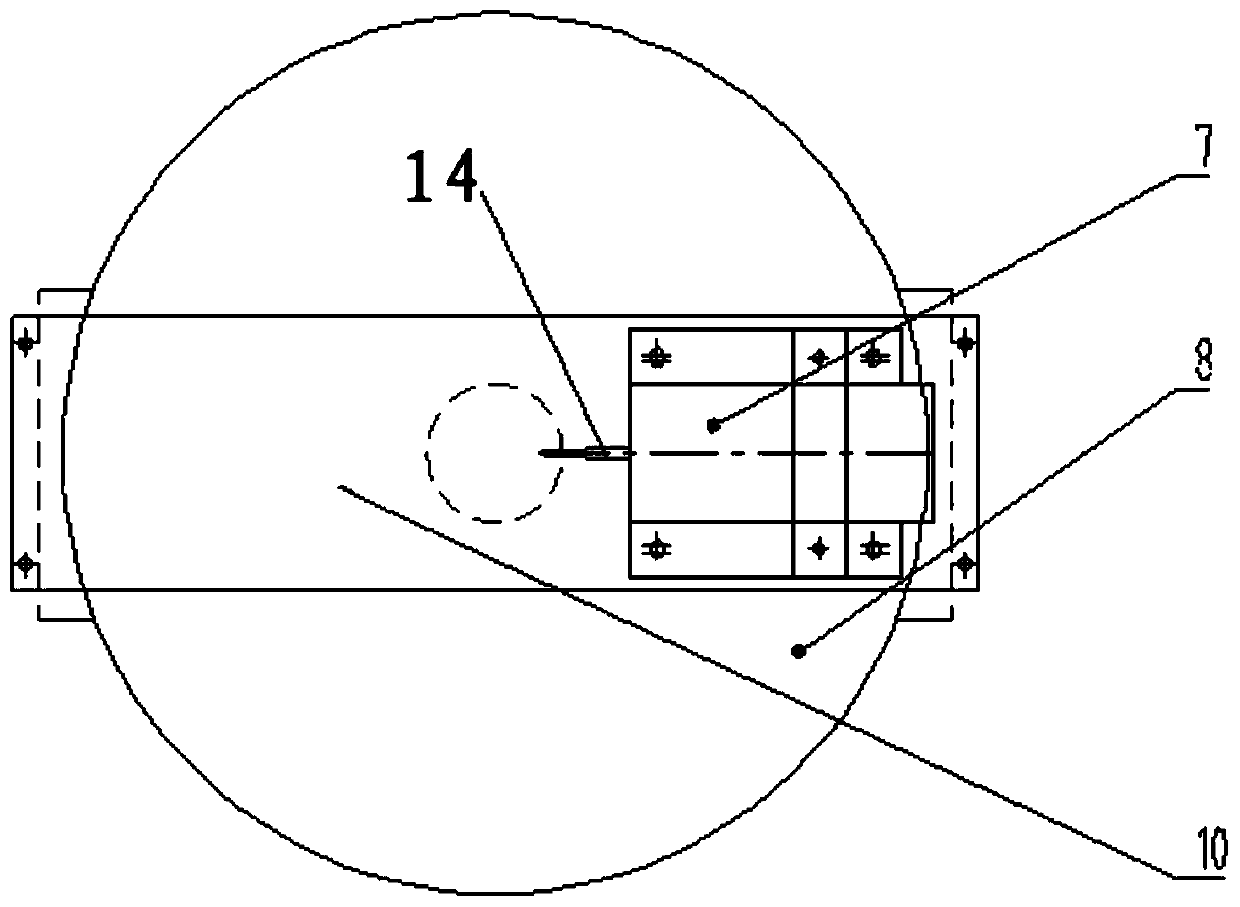

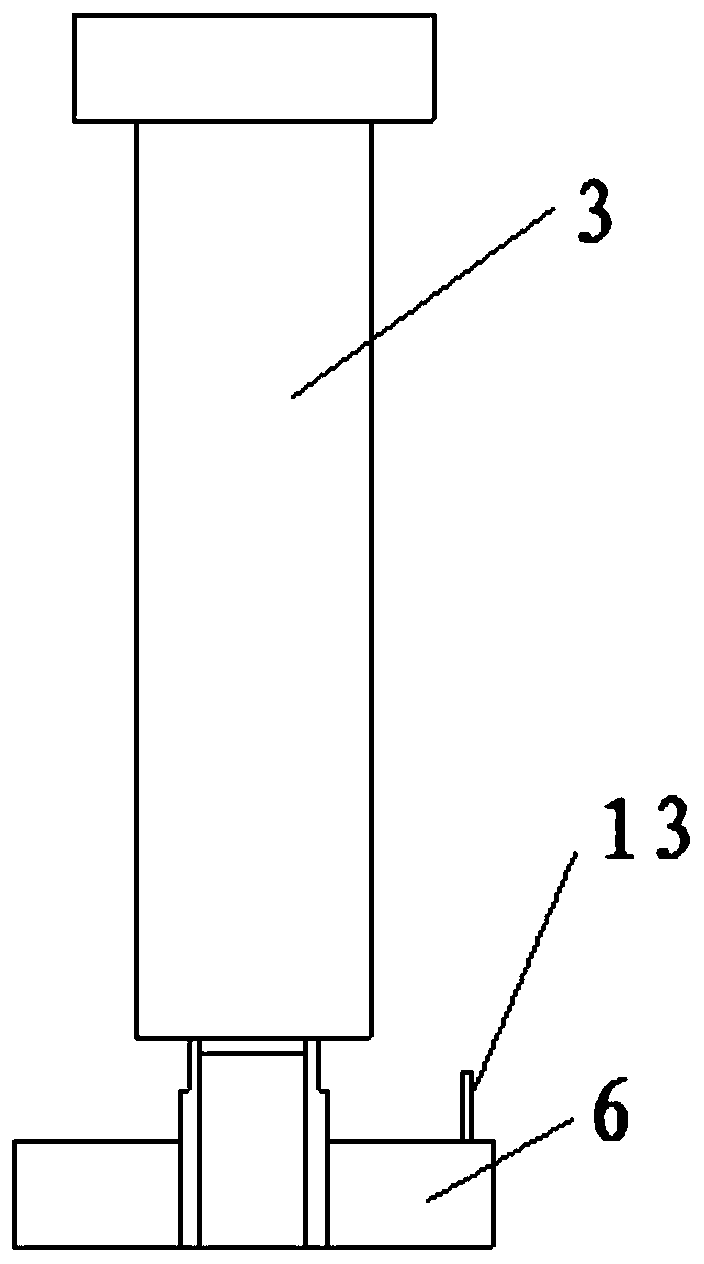

[0023] Such as figure 1 Shown is the front view of the precise measurement device for the friction torque of the conductive slip ring. It can be seen from the figure that the precise measurement device for the friction torque of the conductive slip ring includes a base plate 1, a vertical plate 2, a conductive slip ring 3, a top plate 5, and a slip ring rotor. Ring 6, dynamometer 7, test disc 8, fixed plate 10, and lead wire 12 at the rotor end of the slip ring; among them, the base plate 1 is a rectangular plate structure and is vertically fixed at the bottom end; the vertical plate 2 is a rectangular plate The vertical plate 2 is vertically and fixedly installed on the top of the base plate 1; the top plate 5 is a rectangular plate-shaped structure, and is fixed and installed horizontally on the top of the vertical plate 2 to realize top seali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com