Automatic sampling device

A technology of automatic sampling device and rotating component, which is applied in sampling device, sampling, measuring device and other directions, can solve the problems such as the inability to automatically arrange the plastic case and the long time period of manual operation, and achieve the effect of wide application and improved sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0030] The upper part and the lower part described in the present invention refer to the position of the upper and lower positions of the reactor.

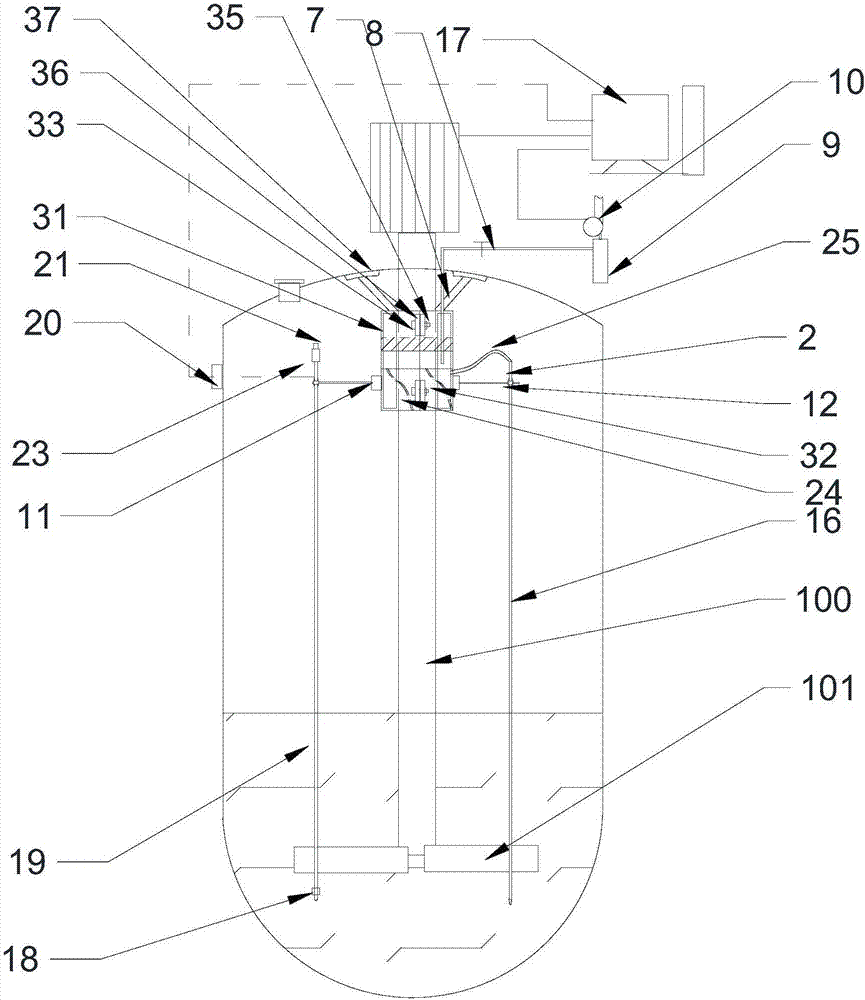

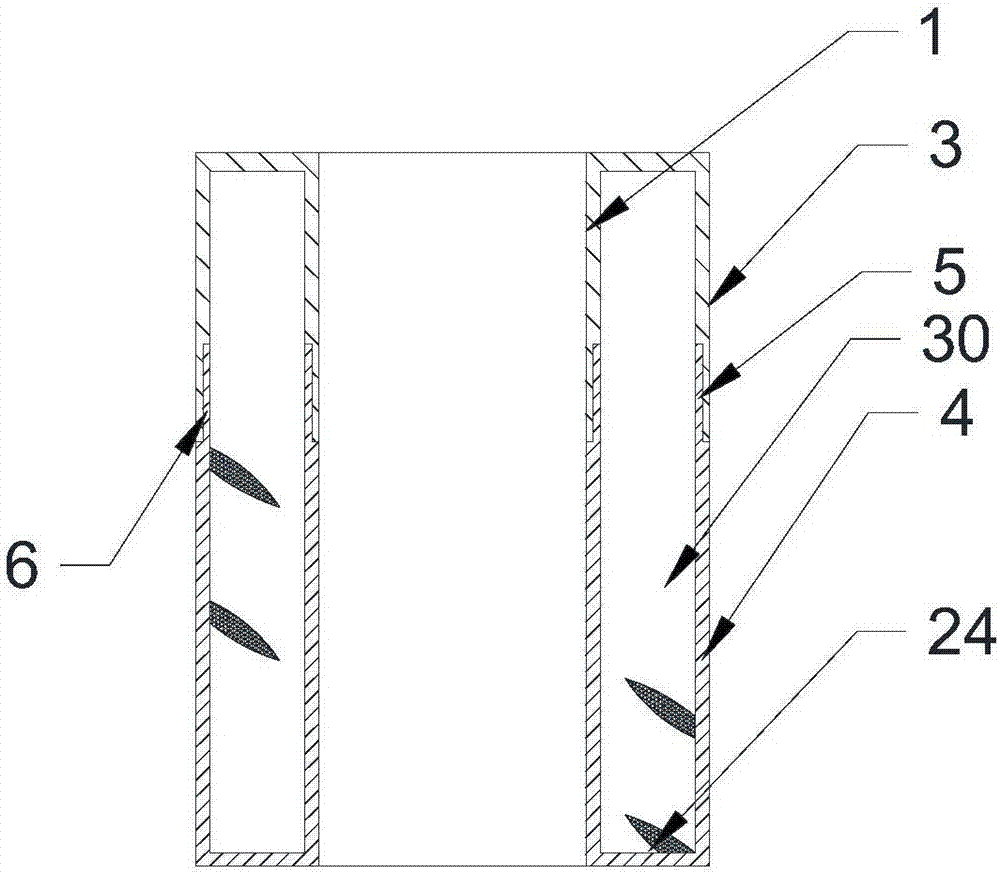

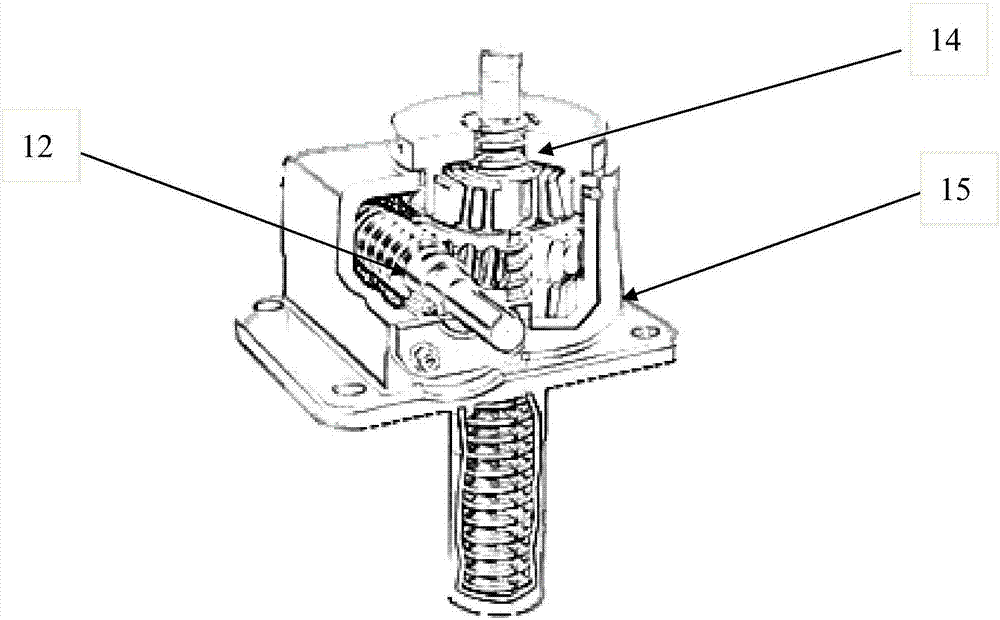

[0031] The invention discloses an automatic sampling device (see attached figure 1 , 2 , 3, 4), for being installed in the reaction kettle, the reaction kettle includes a stirring shaft 100 and a stirring blade 101 installed below the stirring shaft 100; including: a sleeve 1 and a sampling assembly 2 with a liquid storage chamber inside; The sleeve 1 is composed of an annular fixed assembly 3 located at the upper part and an annular rotating assembly 4 located at the lower part;

[0032] The inner wall at the bottom of the annular fixed assembly 3 has an annular inwardly recessed chute 5; the outer wall at the top of the annular rotating assembly 4 has an annular slider 6; the slider 6 is adapted to the chute 5, At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com