Low-frequency disturbance and high-speed impact type high-pressure true triaxial test device and low-frequency disturbance and high-speed impact type high-pressure true triaxial test method

A technology of high-speed impact and test equipment, which is applied in the direction of measuring equipment, testing material strength by applying repetitive force/pulsation force, and testing material strength by applying stable tension/compression, which can solve the problem of being unable to simulate three-dimensional high ground stress state, unable to Further expand the range of disturbance frequency, no reports and other issues, to achieve the effect of reducing self-weight, reducing friction, and expanding the scope of research

Active Publication Date: 2017-08-04

NORTHEASTERN UNIV

View PDF6 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in the current laboratory rock mechanics tests aimed at the critical fracture and dynamic instability of deep rock mass, the low-frequency perturbation tests of rocks are mostly concentrated on uniaxial or conventional triaxial foundations, which cannot simulate the three-dimensional high ground stress state in the real environment

At the same time, restricted by the attenuation of the actuator and the friction factor, the applied disturbance frequency can only reach a maximum of about 10 Hz, and the r

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

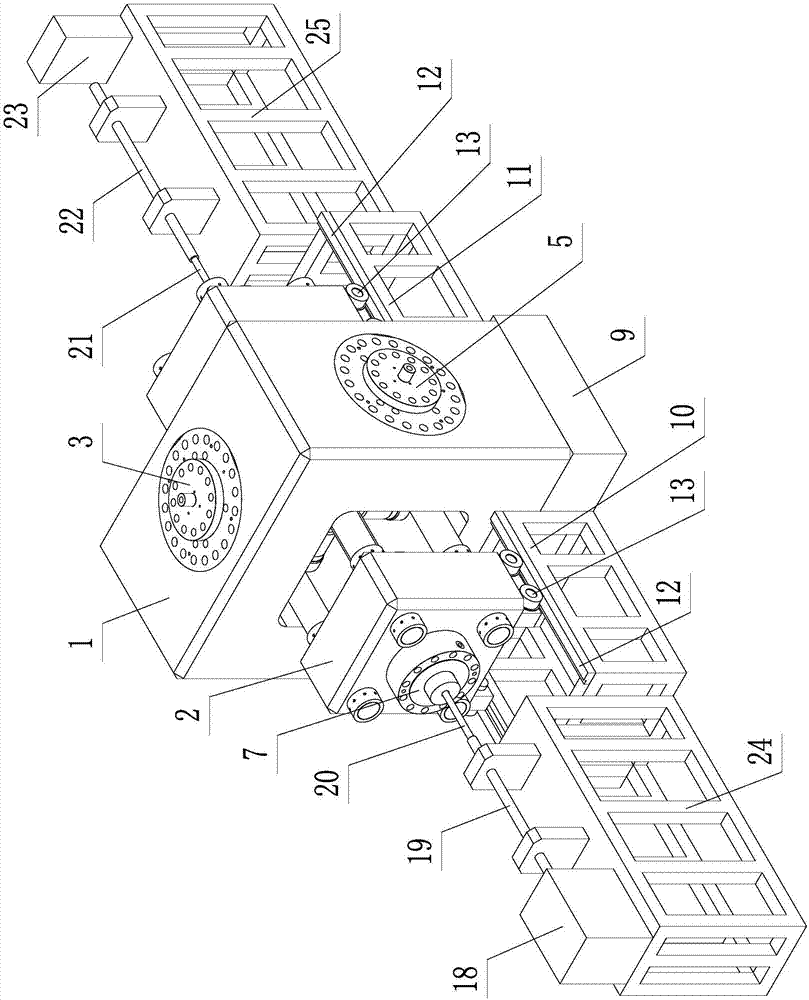

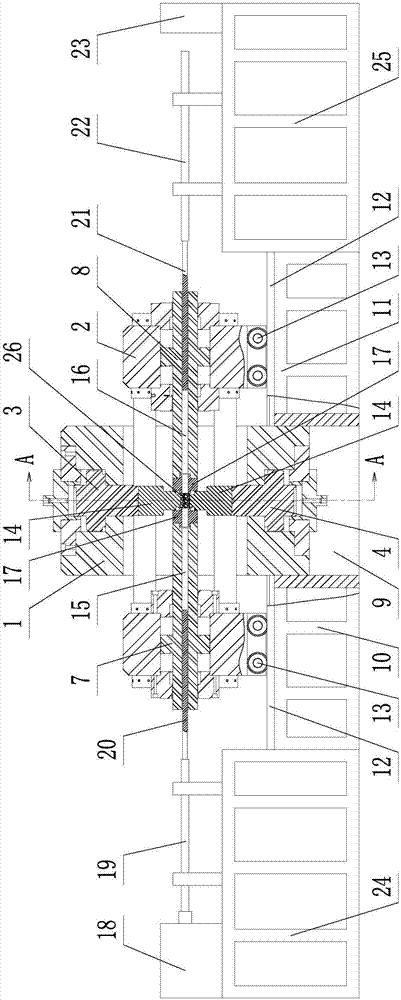

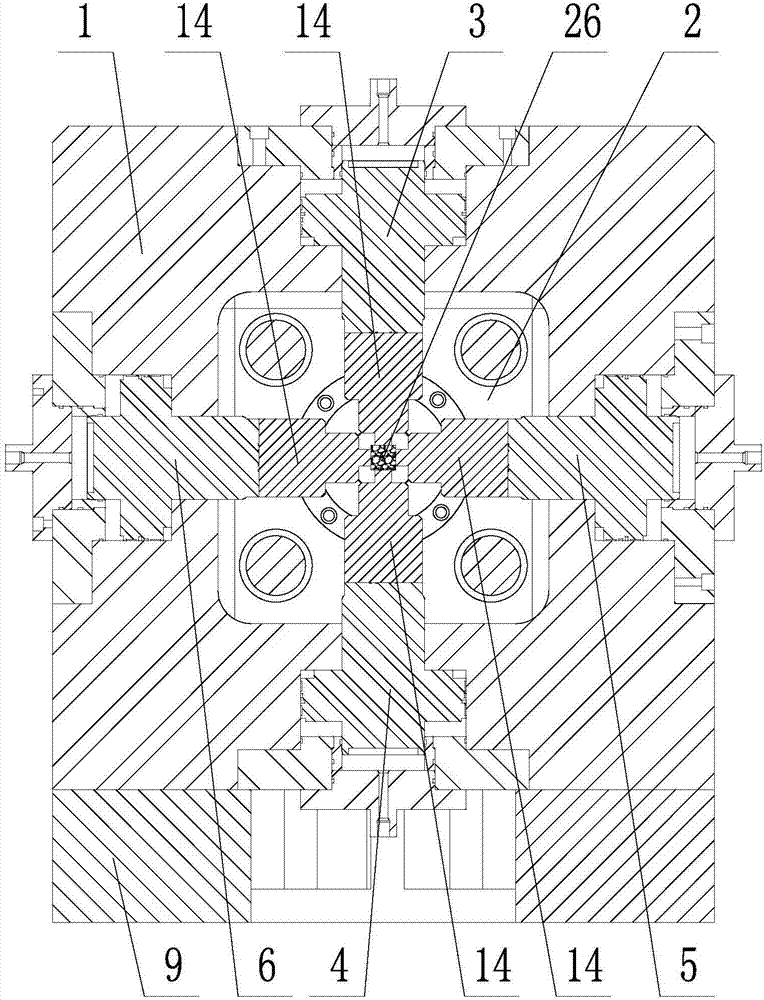

The invention relates to a low-frequency disturbance and high-speed impact type high-pressure true triaxial test device and a low-frequency disturbance and high-speed impact type high-pressure true triaxial test method. The device comprises a dead load loading framework, a dynamic load loading framework, four dead load loading actuators, two dynamic load loading actuators and a split Hopkinson press bar mechanism, wherein all the actuators are connected with an oil source system; hollow ducts are formed in axial centers of piston shafts of the dynamic load loading actuators, dynamic pressure sensors in a hollow annular structure are mounted at the end parts of the piston shafts, and the split Hopkinson press bar mechanism respectively applies high-speed impact loads to a rock sample by virtue of the hollow ducts and the dynamic pressure sensors; the two dynamic load loading actuators adopts a static pressure oil path balancing-supporting sealing manner and are connected with the oil source system through servo valves, energy accumulators are assembled to oil paths, the flow is increased by virtue of the servo valves to drive dynamic response of pistons, and the system pressure during low-frequency disturbance loading is balanced by virtue of the energy accumulators. According to the device and the method, low-frequency disturbance loads and high-speed impact loads are freely applied to the same equipment for the first time.

Description

technical field [0001] The invention belongs to the technical field of indoor rock mechanics tests, in particular to a low-frequency disturbance and high-speed impact high-pressure true triaxial test device and method. Background technique [0002] Deep rock mass is the carrier of deep water conservancy and hydropower projects, deep metal mining, and high-level radioactive nuclear waste disposal. When deep rock mass is excavated, it will be disturbed by blasting and destructive impact, which will often induce a series of damage. Instability or even geological disasters, such as zonal cracking, time-delayed rockburst, impact-type rock pressure and impact-type rockburst, etc., are essentially deep rock masses damaged by excavation and unloading in a state of three-dimensional high ground stress. The phenomenon of critical rupture and dynamic instability occurs under the action of different characteristic dynamic and static loads such as blasting damage, blasting vibration and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12G01N3/36

CPCG01N3/12G01N3/36G01N2203/0026G01N2203/0048G01N2203/0075G01N2203/0256

Inventor 冯夏庭张希巍孔瑞杨成祥彭帅石磊姚志宾田军

Owner NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com