Nucleic acid gel fibers and preparing method thereof

A technology of gel fiber and nucleic acid, which is applied in the fields of fiber chemical characteristics, stretch spinning, rayon manufacturing, etc., can solve the problems of lack of internal structure, hindering practical application, poor mechanical properties, etc., and achieves simple preparation process and regular structure. , the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

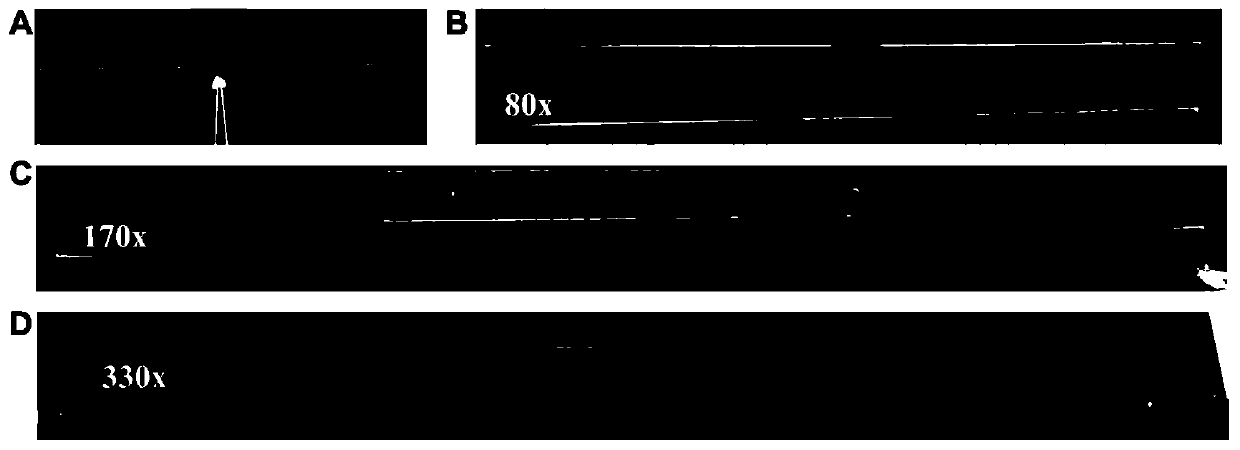

[0035] Take 210 μL of 5.4mM 22bp (22 base pairs) DNA solution and 5mL of 50mM didodecyldimethylammonium bromide into a centrifuge tube, shake and stir for 1 minute to form a white suspension. Then put it into a centrifuge, centrifuge at a centrifugal speed of 10000rpm for 30 minutes, remove the supernatant, add deionized water to wash and centrifuge, remove the supernatant after repeated washing three times, and put the centrifuged complex into the liquid Freeze in nitrogen and freeze dry in a lyophilizer for two hours. Then, 100 μL of toluene was added to the freeze-dried sample, and left at room temperature for 30 minutes to obtain a nucleic acid gel, and the nucleic acid gel was drawn to obtain a nucleic acid gel fiber. figure 1 The nucleic acid gel prepared for this example shows that the nucleic acid gel of the present invention has a liquid crystal structure.

Embodiment 2

[0037] Take 210 μL of 5.4mM DNA solution (200 base pairs) and 5mL of 50mM didodecyldimethylammonium bromide into a centrifuge tube, shake and stir for 1 minute to form a white suspension. Then put it into a centrifuge, centrifuge at a centrifugal speed of 10000rpm for 30 minutes, remove the supernatant, add deionized water to wash and centrifuge, remove the supernatant after repeated washing three times, and put the centrifuged complex into the liquid Freeze in nitrogen and freeze dry in a lyophilizer for two hours. Then, 100 μL of toluene was added to the freeze-dried sample, and left at room temperature for 30 minutes to obtain a nucleic acid gel, and the nucleic acid gel was drawn to obtain a nucleic acid gel fiber. figure 1 The nucleic acid gel prepared for this example shows that the nucleic acid gel of the present invention has a liquid crystal structure.

Embodiment 3

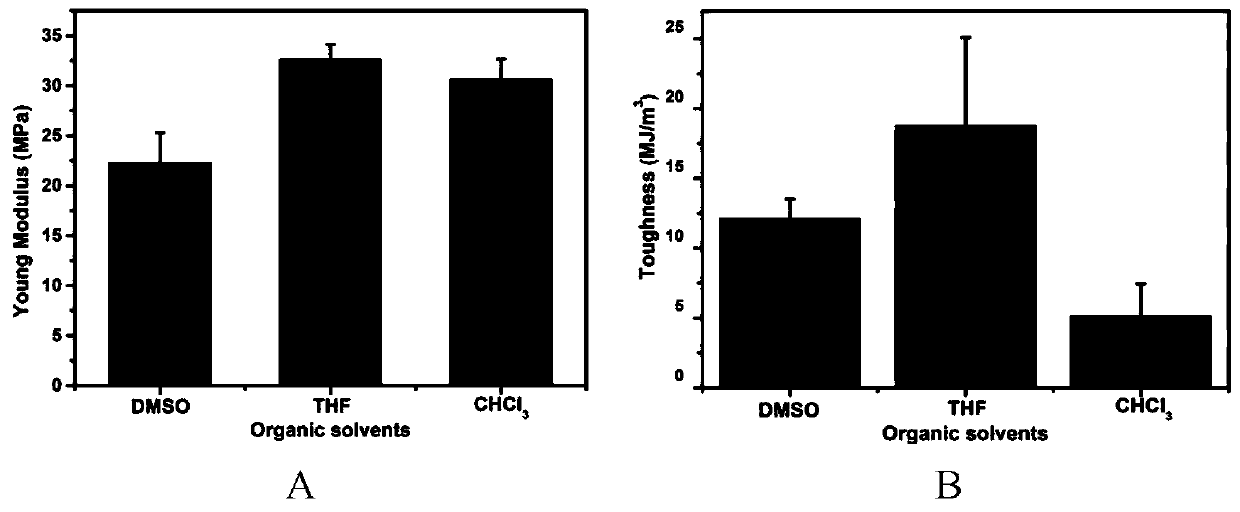

[0039] Take 210 μL of 5.4mM DNA solution (1000 base pairs) and 5mL of 50mM didodecyldimethylammonium bromide into a centrifuge tube, shake and stir for 1 minute to form a white suspension. Then put it into a centrifuge, centrifuge at a centrifugal speed of 10000rpm for 30 minutes, remove the supernatant, add deionized water to wash and centrifuge, remove the supernatant after repeated washing three times, and put the centrifuged complex into the liquid Freeze in nitrogen and freeze dry in a lyophilizer for two hours. Then, 100 μL of toluene was added to the freeze-dried sample, and left at room temperature for 30 minutes to obtain a nucleic acid gel, and the nucleic acid gel was drawn to obtain a nucleic acid gel fiber. figure 2 The nucleic acid gel extensibility experiment prepared for this embodiment shows that the nucleic acid liquid crystal gel has a large elongation at break.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com