Nitrogen-containing hierarchical porous carbon/graphene composite material, preparation method and application thereof

A composite material, graphene technology, applied in the field of materials, can solve the problems of increasing electrolyte ion transport resistance, supercapacitor capacitance performance impact, low specific surface area utilization, etc., to enhance the pseudocapacitance effect, avoid stacking and agglomeration, high Effect of magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

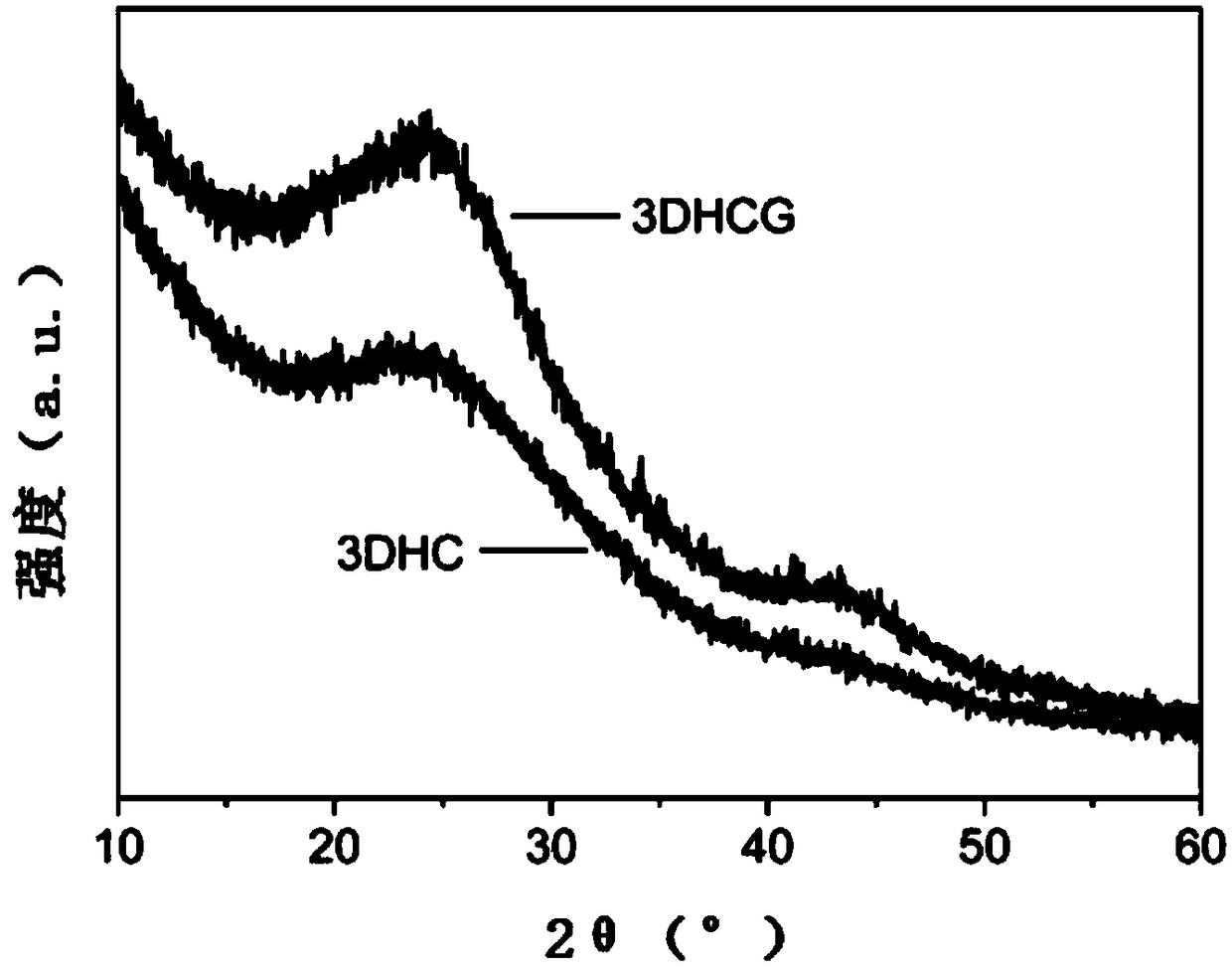

Embodiment 1

[0033] Disperse 2mg of graphene oxide powder in 20mL of deionized water and ultrasonicate for 1h to obtain a stably dispersed graphene oxide dispersion with a concentration of 0.1mg / mL; then add 0.5g of chitosan and 20mL of acetic acid to the graphene oxide dispersion solution (0.5vol.%), stirred at room temperature for 1 h to form a uniformly dispersed mixed solution. Add 0.4 mL of glutaraldehyde solution (25wt.%) to the above mixed solution under stirring as a cross-linking agent. After uniform dispersion, leave the mixed solution at room temperature to allow the solution to undergo a cross-linking reaction until it is completely cross-linked. A clear hydrogel was obtained. The fully cross-linked hydrogels were subjected to hierarchical freezing at 4°C, 0°C, and -20°C in sequence, and then freeze-dried in a freeze dryer to obtain chitosan / graphene airgel materials with a multi-level pore structure. ; Move the chitosan / graphene airgel material to a tube furnace, raise the te...

Embodiment 2

[0037]Disperse 4mg of graphene oxide powder in 20mL of deionized water, and ultrasonicate for 1h to obtain a stably dispersed graphene oxide dispersion with a concentration of 0.2mg / mL; then add 0.5g of chitosan and 20mL of acetic acid to the graphene oxide dispersion solution (0.5vol.%), stirred at room temperature for 1 h to obtain a uniformly dispersed mixed solution; under stirring conditions, 0.4 mL of glutaraldehyde solution (25 wt.%) was added to the mixed solution as a cross-linking agent, and after uniform dispersion, the Put it down to make the mixed solution undergo cross-linking reaction until it is completely cross-linked to obtain a transparent hydrogel; the fully cross-linked hydrogel is first subjected to graded freezing at 4°C, 0°C, and -20°C, and then freeze-dried Freeze-dry in the machine to obtain the chitosan / graphene airgel material with multi-level pore structure; move the chitosan / graphene airgel material to a tube furnace, and heat it at a temperature o...

Embodiment 3

[0041] Disperse 10mg of graphene oxide powder in 20mL of deionized water, and ultrasonicate for 1h to obtain a stably dispersed graphene oxide dispersion with a concentration of 0.5mg / mL; then add 0.5g of chitosan and 20mL of acetic acid to the graphene oxide dispersion solution (0.5vol.%), stirred at room temperature for 1h to form a uniformly dispersed mixed solution; continue to stir and add 0.4mL glutaraldehyde solution (25wt.%) to this mixed solution as a cross-linking agent, after the dispersion is uniform, the The mixed solution was left standing at room temperature to allow the solution to undergo a cross-linking reaction until it was completely cross-linked to obtain a transparent hydrogel; the fully cross-linked hydrogel was first graded and frozen at 4°C, 0°C, and -20°C. Then freeze-dry in freeze dryer, obtain the chitosan / graphene airgel material of multi-level hole structure, then chitosan / graphene airgel is moved in the tube furnace, the tube furnace temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com