A kind of preparation method of nitrogen-doped carbon nanotube/porous carbon

A technology of carbon nanotubes and porous carbon, which is applied in the direction of carbon nanotubes, carbon preparation/purification, nano-carbon, etc., can solve the problems of low specific surface area, limit the performance and utilization of carbon material electric double layer capacitance, etc., and achieve the purpose of increasing doping Effects of impurity, reduction of amorphous carbon structure, promotion of uniform dispersion and stable doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

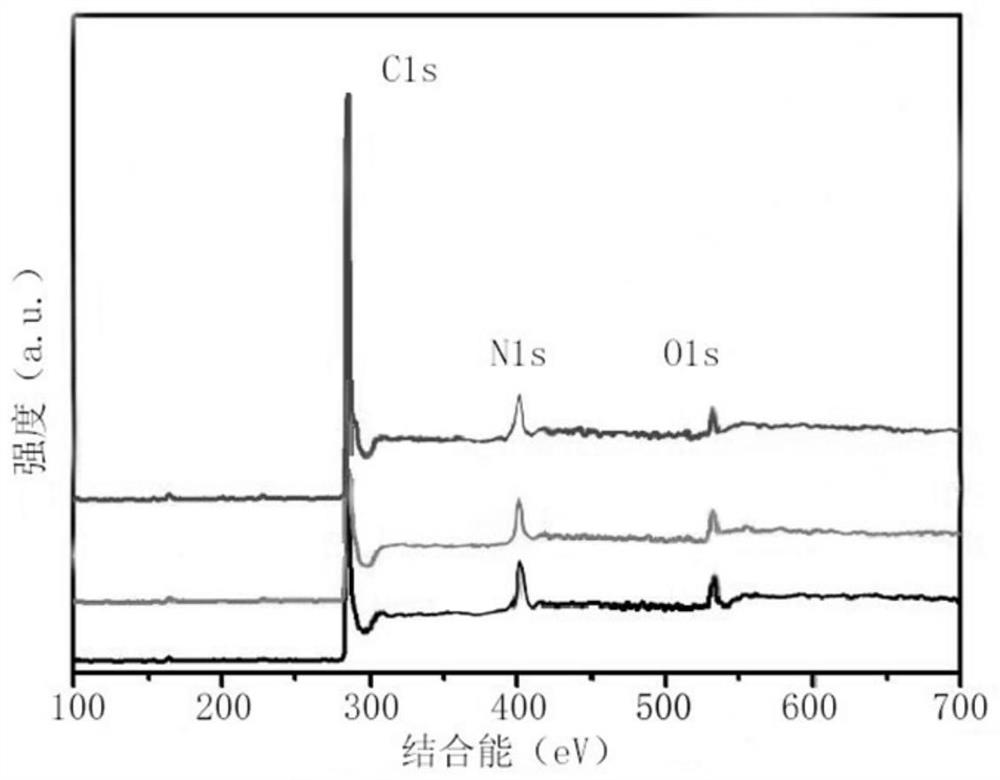

[0036] A method for preparing nitrogen-oxygen-doped carbon nanotubes / porous carbon, comprising: providing aniline monomers to polymerize to form polyaniline particles, performing carburizing treatment on the polyaniline particles to obtain precursor pellets, and pre-oxidizing the precursor pellets treatment and pyrolysis treatment. The nitrogen and oxygen atoms in the composite carbon material introduce electron acceptor characteristics into the structure of the composite carbon material to generate a pseudocapacitive reaction, increase the wettability of the interface between the electrode material and the electrolyte, and have a positive effect on the wetting of the porous carbon pore wall. By further increasing The exposed surface of the composite carbon material further improves the charge storage capacity, enabling the composite carbon material to obtain a large specific capacity, high rate performance and excellent cycle stability.

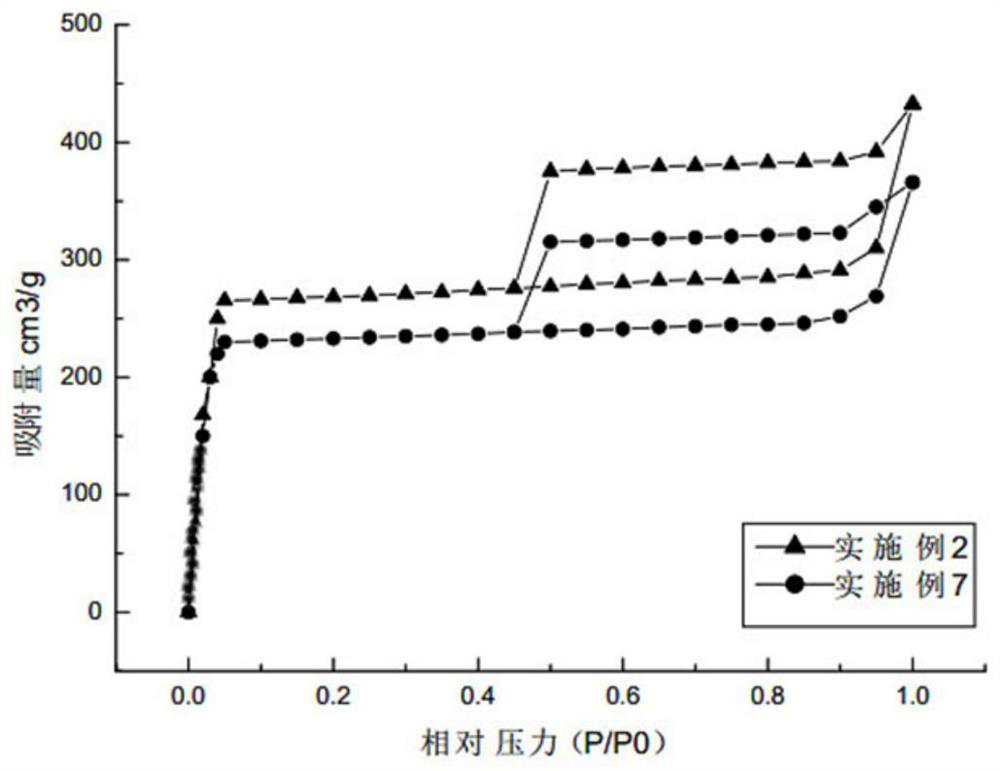

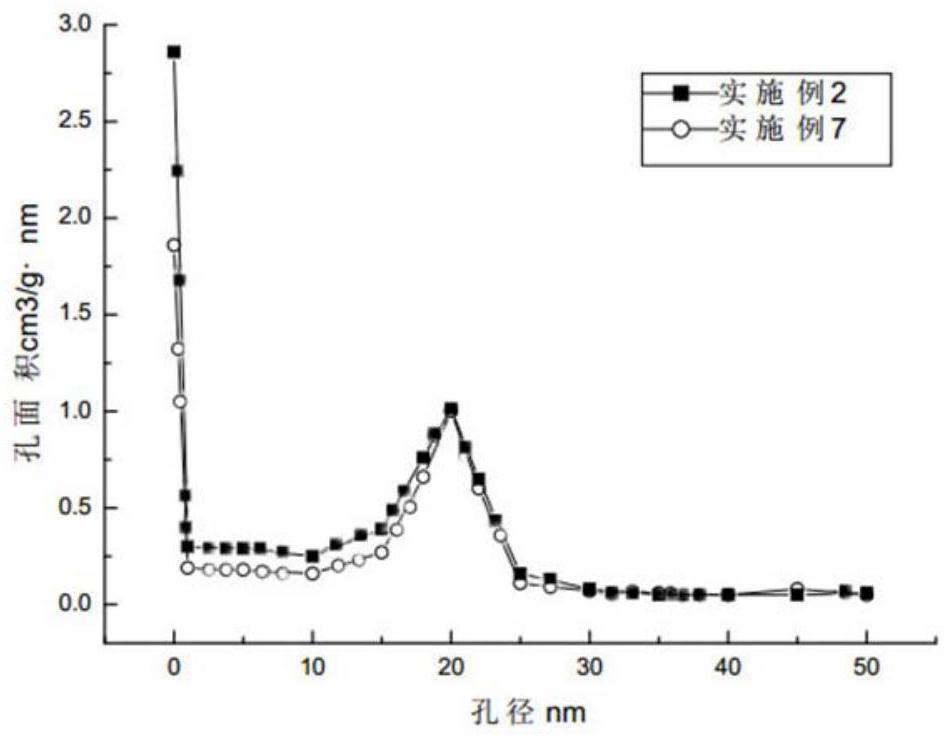

Embodiment 2

[0047] A preparation method of nitrogen-oxygen-doped carbon nanotube / porous carbon, comprising the following specific steps:

[0048] 1) Add 8 times the amount of aniline monomer into a 0.1mol / L dilute hydrochloric acid solution, stir and dissolve to obtain a mixed solution A, then stir and dissolve ammonium persulfate in 5 times the amount, 0.1mol / L dilute hydrochloric acid solution to obtain a mixed solution B. After cooling the two to 0°C respectively, pour the mixed solution B into the mixed solution A and stir for 3 minutes, then magnetically stir in an ice bath at 0°C for 8.5 hours, then centrifuge the resulting dark green precipitate, and then use 0.1mol / L Aqueous ammonia solution and deionized water were washed to neutrality, and after the filtrate was colorless, it was dried at 80°C to obtain polyaniline particles, and the molar ratio of the above-mentioned aniline to ammonium persulfate was 1.25:1;

[0049] 2) After mixing the obtained polyaniline particles with the ...

Embodiment 3

[0054] The differences between this embodiment and embodiment 2 are:

[0055] Step 5) Mix the quartz plate product and the quartz boat product evenly to obtain a mixed powder, then add 2mol / L dilute nitric acid solution, and after ultrasonic stirring at a temperature of 90°C for 20min, centrifuge, and the resulting precipitate is washed with deionized water until Neutral, the filtrate is colorless and then dried at 130°C to obtain a nitrogen-oxygen-doped carbon nanotube / porous carbon composite carbon material. The above dilute nitric acid solution contains 0.05mM citric acid and 0.03mM pentaerythritol, and the mixed powder Under the action of ultrasonic waves, the carbon nanotubes are easy to bombard the carbon nanotubes to knock out carbon atoms, and the carbon atoms stay in the interstitial positions of the lattice to generate interstitial atoms. The interstitial atoms will cause further defects in the carbon structure lattice and form on the composite carbon material. A sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com