Preparation method of composite electrode material

A composite electrode and mixed solution technology, applied in the field of materials, can solve the problems of limited application prospects, high cost of electrode material preparation, high cost of carbon nanotubes and graphene, etc., to achieve simple process flow, improve electrochemical performance, and increase pseudocapacitance effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

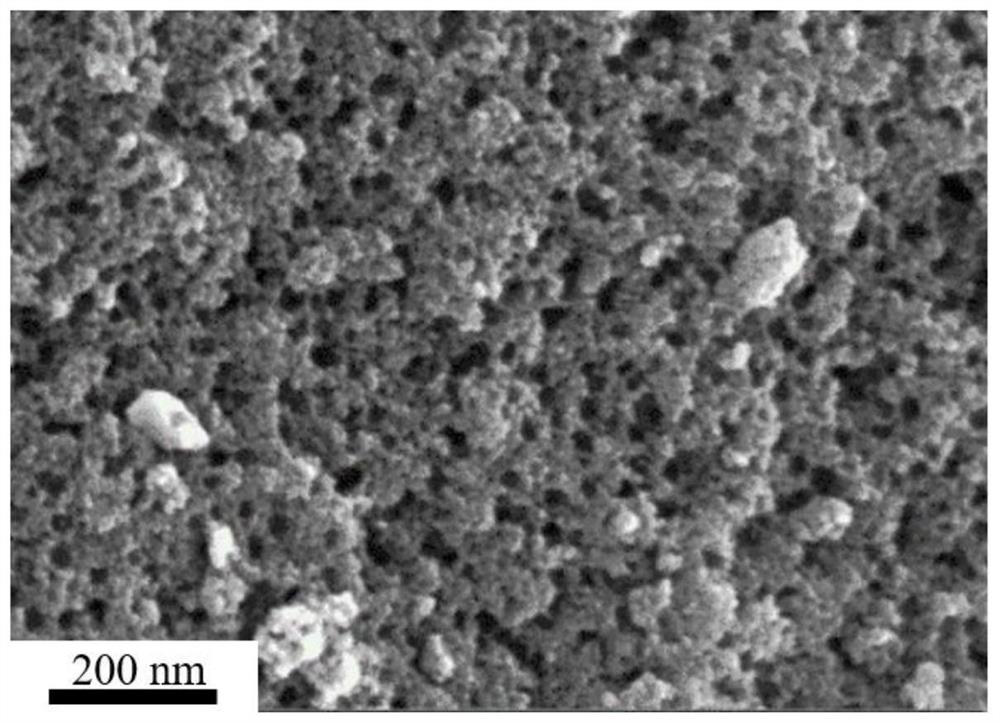

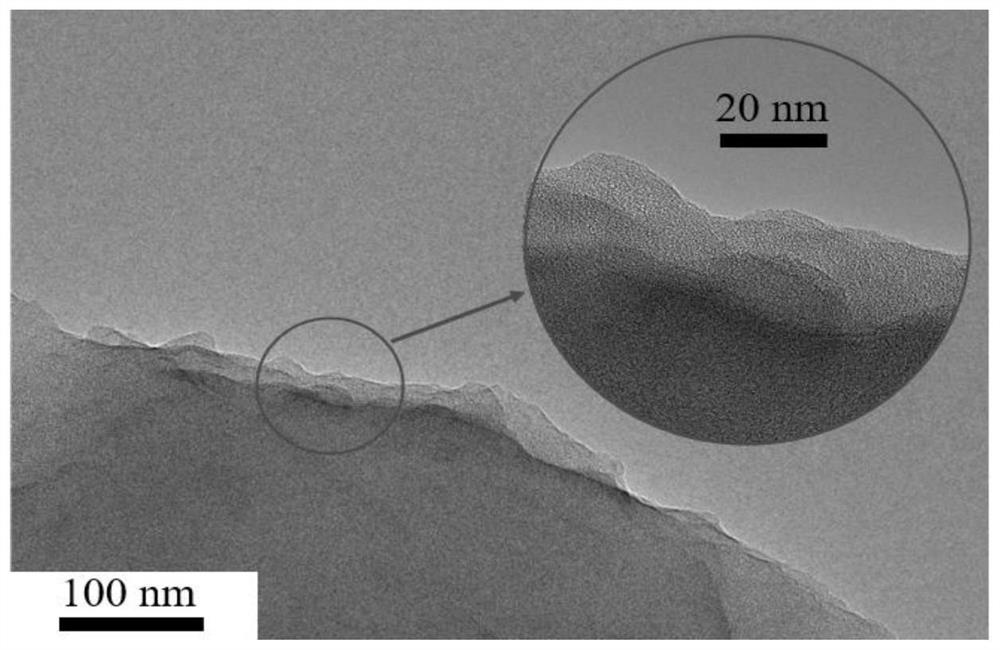

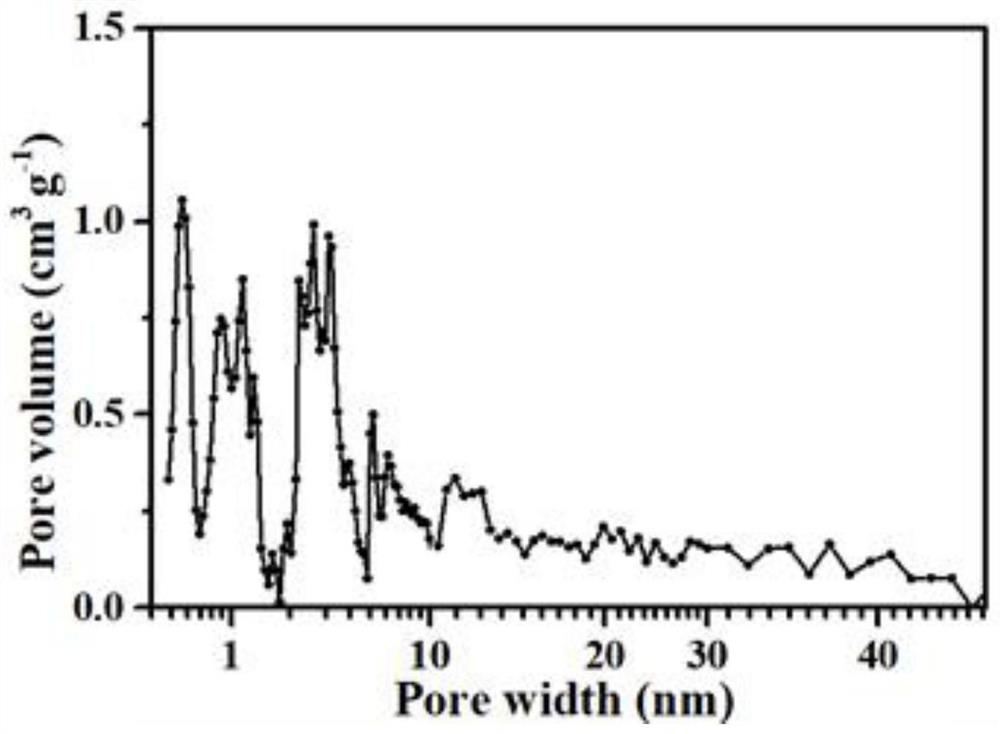

[0034] At an ambient temperature of 25°C, the bulkMoS 2 The powder and the surface dispersant sodium cholate were added into the ball mill tank at a mass ratio of 1:2, and ball milled at a speed of 150r / min for 3h. Then the ball-milled mixture was washed with a small amount of deionized water and centrifuged at 6000r / min for 30min to separate the unexfoliated MoS 2 , take out the supernatant to get MoS 2 nanosheet dispersion. At the same time, take 400mg PAN and add it to 2ml deionized water and 3g ZnCl 2 In a beaker, stir until completely dissolved. Then the resulting MoS 2 Nanosheet dispersion and ZnCl 2 Solution dissolved PAN mixed (MoS 2 The mass ratio to PAN is 3:100), stirred at a speed of 300r / min to make it evenly mixed to obtain PAN / MoS 2nanosheet composites. The composite was heated to 220 °C at a heating rate of 5 °C / min in air atmosphere, and kept for 1 h for pre-oxidation treatment. Subsequently, the product was heated to 800 °C for 2 h at a heating rate ...

Embodiment 2

[0040] At an ambient temperature of 20°C, the bulk MoS 2 The powder and the surface dispersant sodium cholate were added into the ball mill tank at a mass ratio of 1:3, and ball milled at a speed of 150r / min for 3h. Then the ball-milled mixture was washed with a small amount of deionized water and centrifuged at 6000r / min for 30min to separate the unexfoliated MoS 2 , take out the supernatant to get MoS 2 nanosheet dispersion. At the same time, take 400mg PAN and add it to 2ml deionized water and 3g ZnCl 2 In a beaker, stir until completely dissolved. Then the resulting MoS 2 Nanosheet dispersion and ZnCl 2 Solution dissolved PAN mixed (MoS 2 The mass ratio to PAN is 4.5:100), stirred at a speed of 300r / min to make it evenly mixed to obtain PAN / MoS 2 nanosheet composites. The composite was heated to 200°C at a heating rate of 5°C / min in an air atmosphere, and kept for 1h for pre-oxidation treatment. Then the product was heated to 800 °C at a heating rate of 5 °C / min u...

Embodiment 3

[0042] At an ambient temperature of 15°C, the bulk MoS 2 The powder and the surface dispersant sodium cholate were added into the ball mill tank at a mass ratio of 1:2, and ball milled at a speed of 150r / min for 3h. Then the ball-milled mixture was washed with a small amount of deionized water and centrifuged at 6000r / min for 30min to separate the unexfoliated MoS 2 , take out the supernatant to get MoS 2 nanosheet dispersion. At the same time, take 400mg PAN and add it to a mixture containing 2ml deionized water and 4g ZnCl 2 In a beaker, stir until completely dissolved. Then the resulting MoS 2 Nanosheet dispersion and ZnCl 2 Solution dissolved PAN mixed (MoS 2 The mass ratio to PAN is 6:100), stirred at a speed of 300r / min to make it evenly mixed to obtain PAN / MoS 2 nanosheet composites. The composite was pre-oxidized by heating to 220°C at a heating rate of 5°C / min in an air atmosphere and holding it for 1h. Subsequently, the product was heated to 700 °C for 2 h a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com