Fault-tolerant control method for position sensor fault of brushless direct current motor rotor

A sensor failure, brushed DC motor technology, applied in the direction of motor control, electronic commutation motor control, control system, etc., can solve problems such as motor failure, achieve the effect of reducing impact, improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

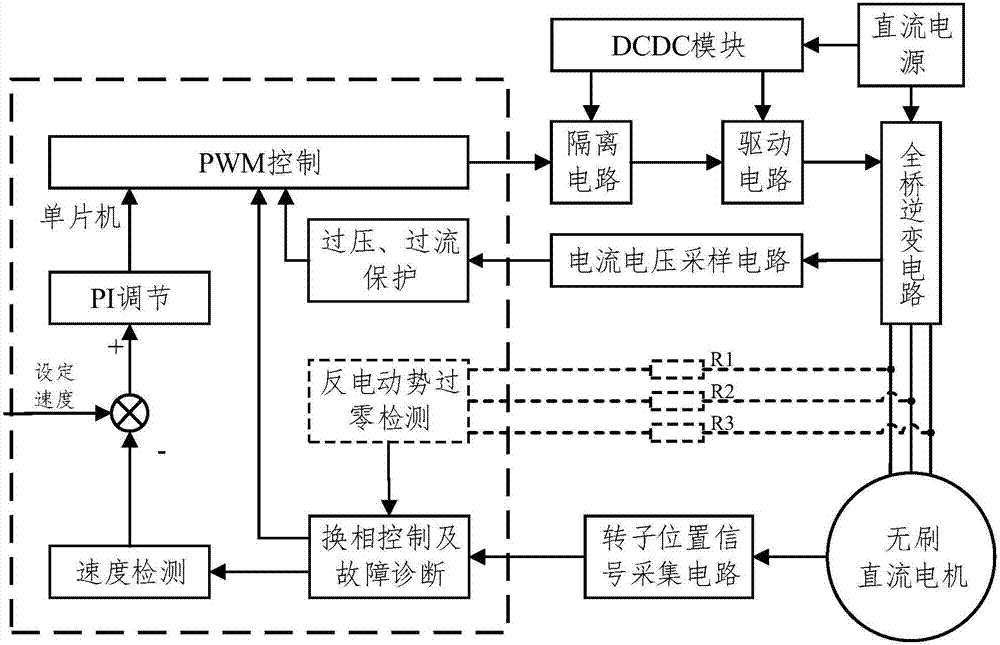

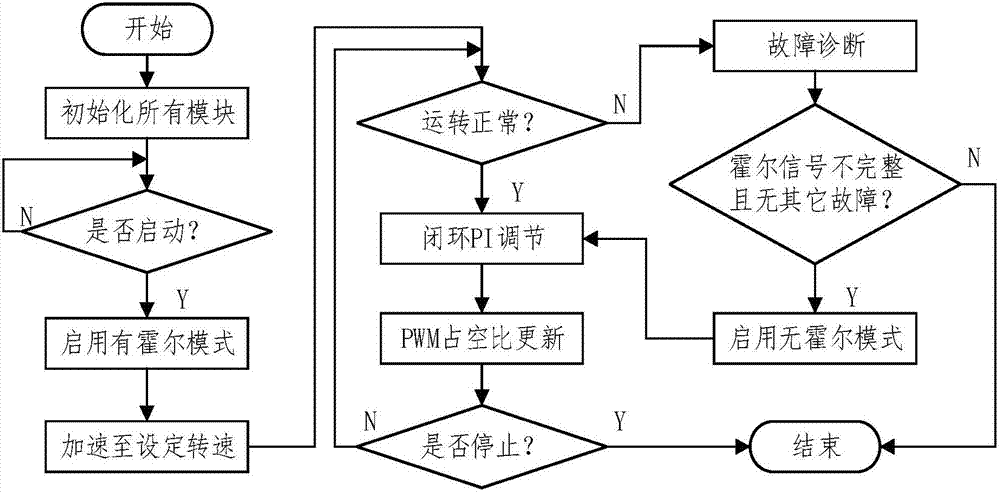

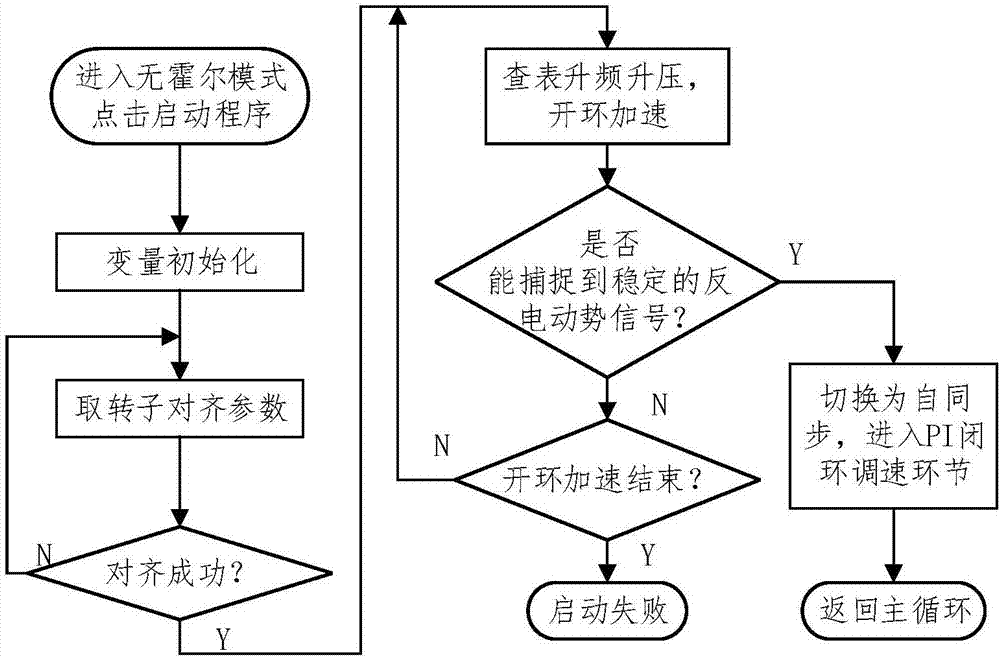

[0016] The control system integrates Hall control and Hallless control. The Hall signal is used as the basis for commutation with Hall control, and the counter electromotive force signal is used as the basis for commutation without Hall control. The current motor speed determines the current control mode.

[0017] When the motor control system is powered on and detects that the Hall sensor is working normally, it will start in the Hall control mode and drive the motor to run.

[0018] When the motor control system detects that the Hall sensor fails and cannot work normally after it is powered on, it will automatically switch to the non-Hall control mode to start and drive the motor to run.

[0019] When the motor is running in the Hall control mode and the Hall sensor fails, if the current speed meets the condition that the back electromotive force signal is used as the basis for motor commutation, it will automatically switch to the non-Hall control mode and continue to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com