Pickup device of suspension type residual film recovering and bundling combined operation machine

A combined operation machine and residual film recovery technology, which is applied in the field of agricultural machinery, can solve the problems of increased production labor costs, easy to be broken, low tensile strength, etc., to improve the picking effect, easy maintenance and replacement, and institutional structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

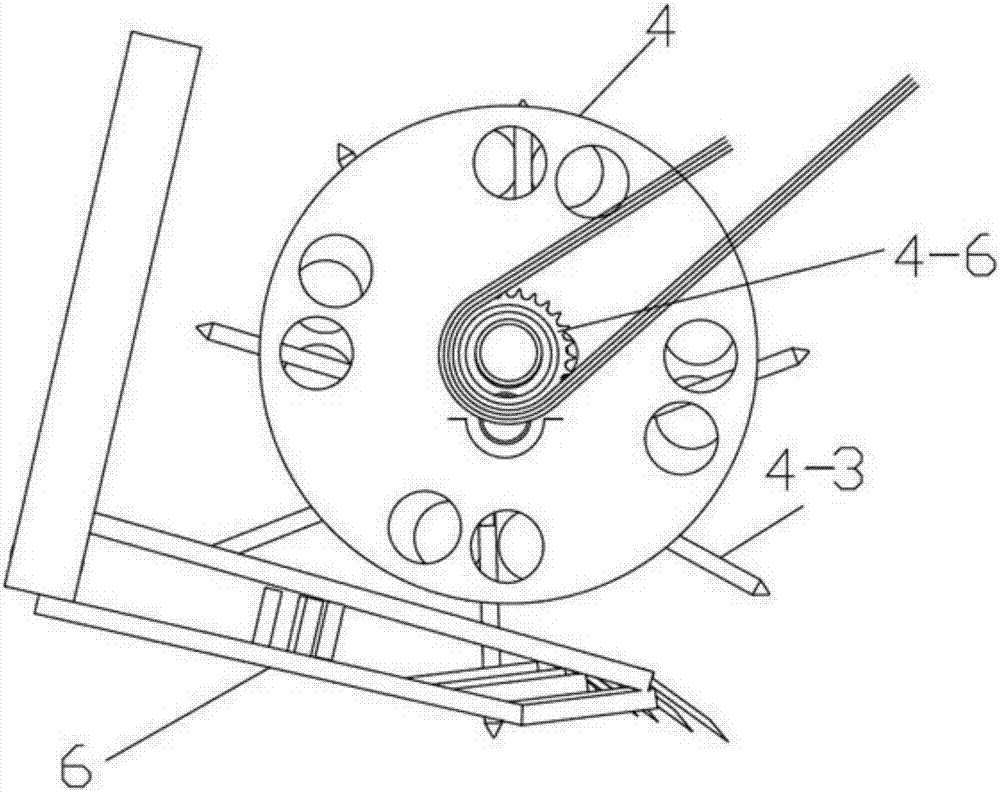

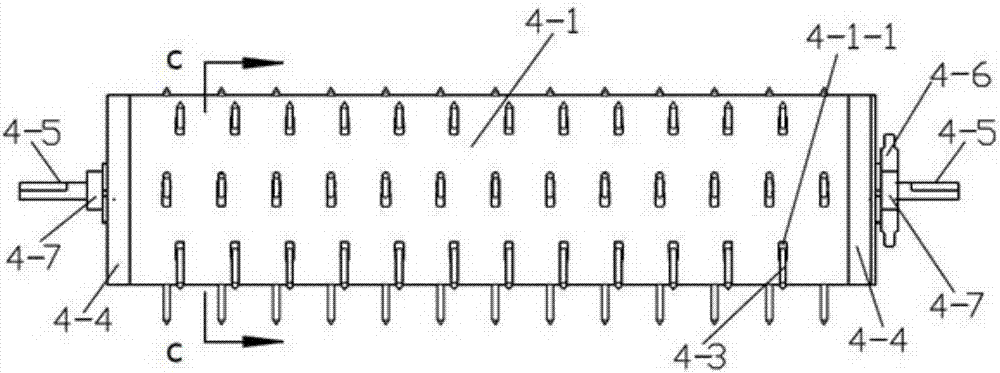

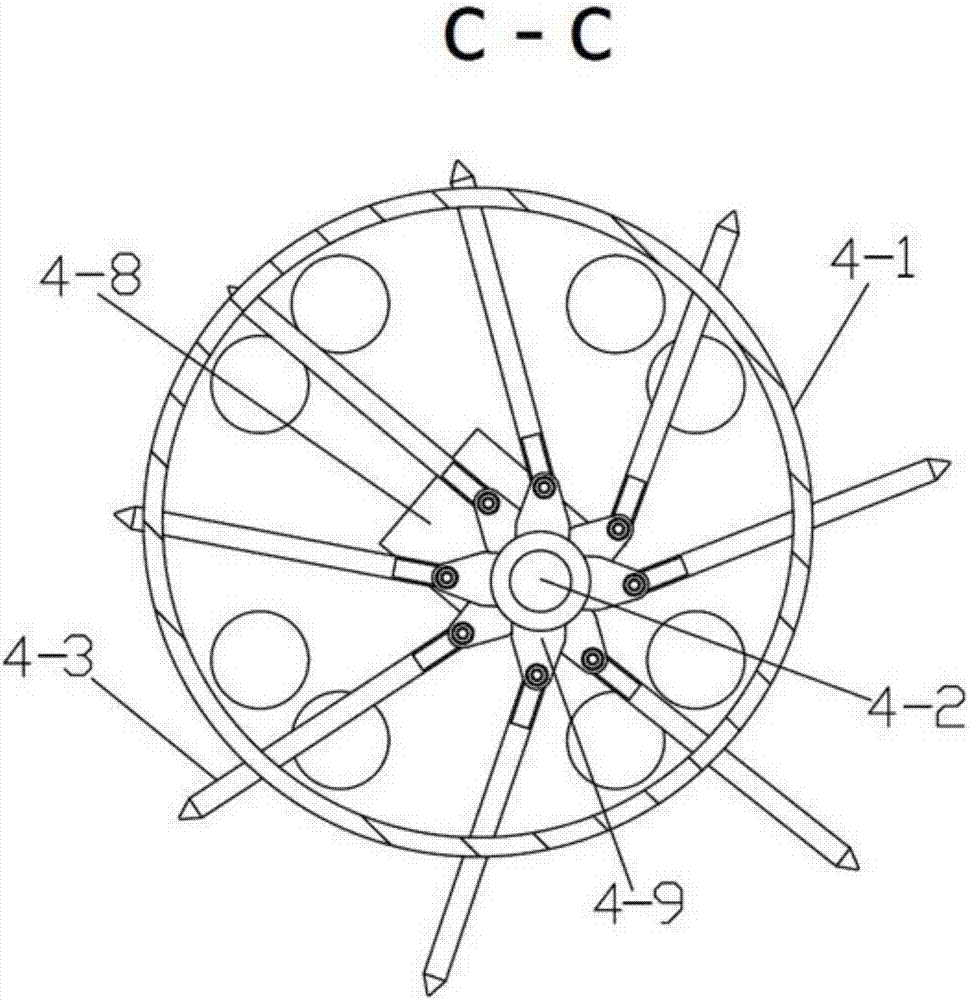

[0018] Depend on Figure 1-5 As can be seen from the shown embodiment, the present embodiment includes a film comb 6 and a rotating pick-up 4 that are arranged on the suspension frame 2; The residual film is picked up, and the rotating pick-up device 4 is located above the film comb 6. The rotating pick-up device 4 includes a drum 4-1 that is rollingly connected with the suspension frame 2, and the drum 4-1 is provided with a transmission connection with the driving device. transmission structure, the rotation direction of the drum is opposite to that of the support wheels of the suspension frame 2, and the body of the drum 4-1 is evenly distributed with the constraint strip holes 4-1-1 and the strip holes 4-1-1 The length direction is consistent with the circumferential direction of the drum 4-1, and corresponds to the gap of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com