Automatic classifying tangerine picking machine

An automatic grading and picking machine technology, applied to picking machines, grading, harvesters, etc., can solve the problems of low work efficiency, heavy operator workload, and inability to adapt to a large number of picking in a short time, and achieve fast positioning and fast picking stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

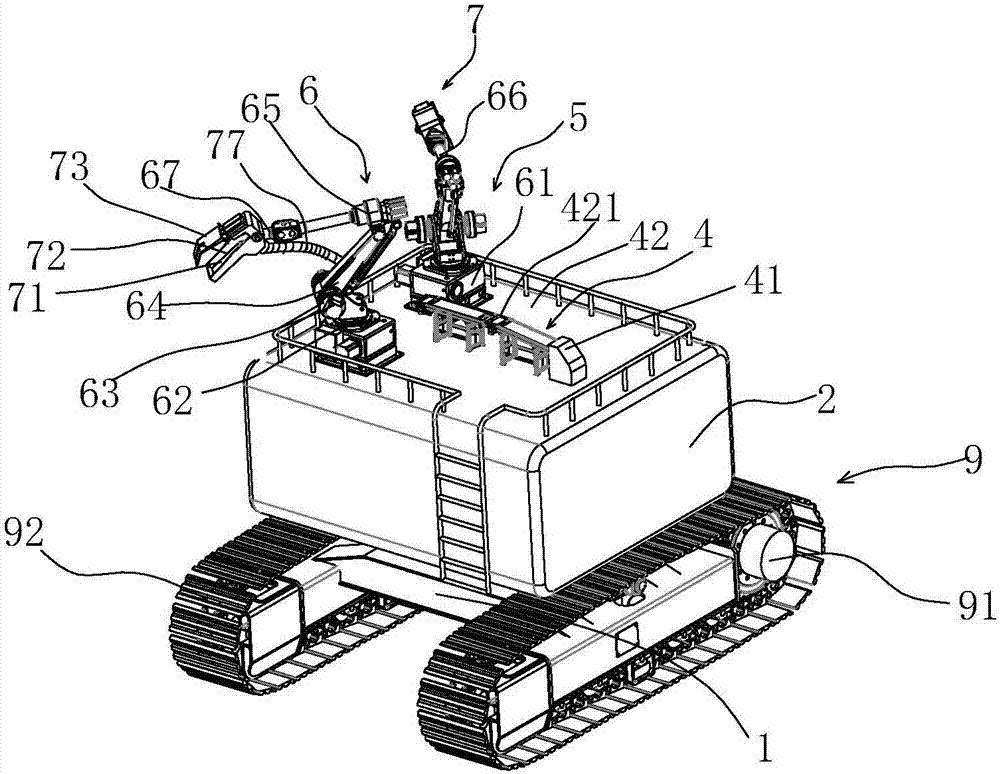

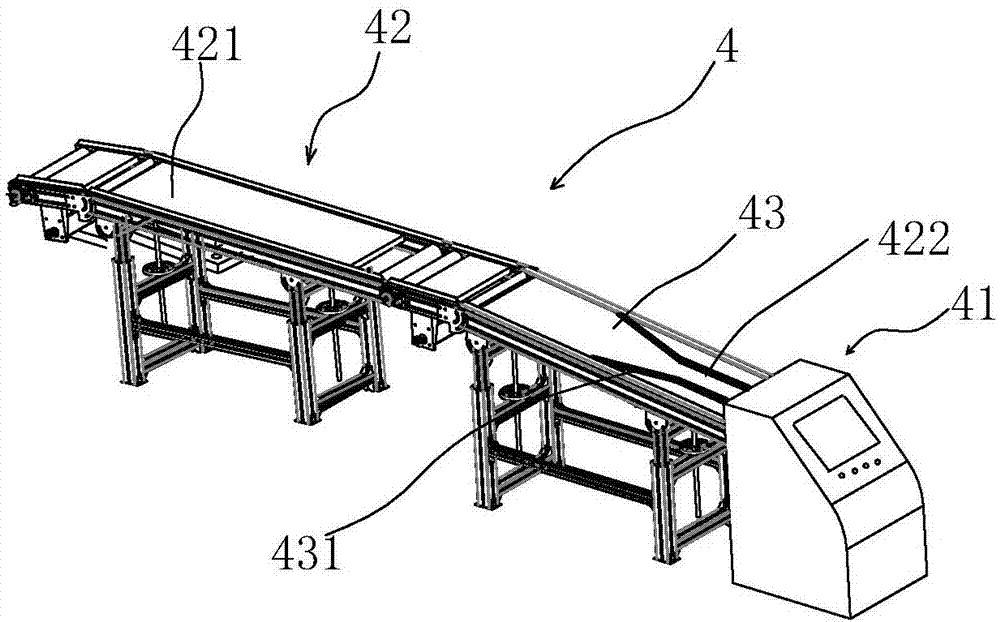

[0025] like figure 1 As shown, an automatic grading orange picking machine includes a machine base 1. Above the base 1, there is a grading warehouse 2 that is divided into several adjustable and relatively independent chambers. Above the grading warehouse 2 A classifier 3 is provided across the grading warehouse 2 , an operation table 4 is arranged above the classifier 3 , and mutually independent picking mechanisms 5 are respectively arranged on both sides of the operation table 4 .

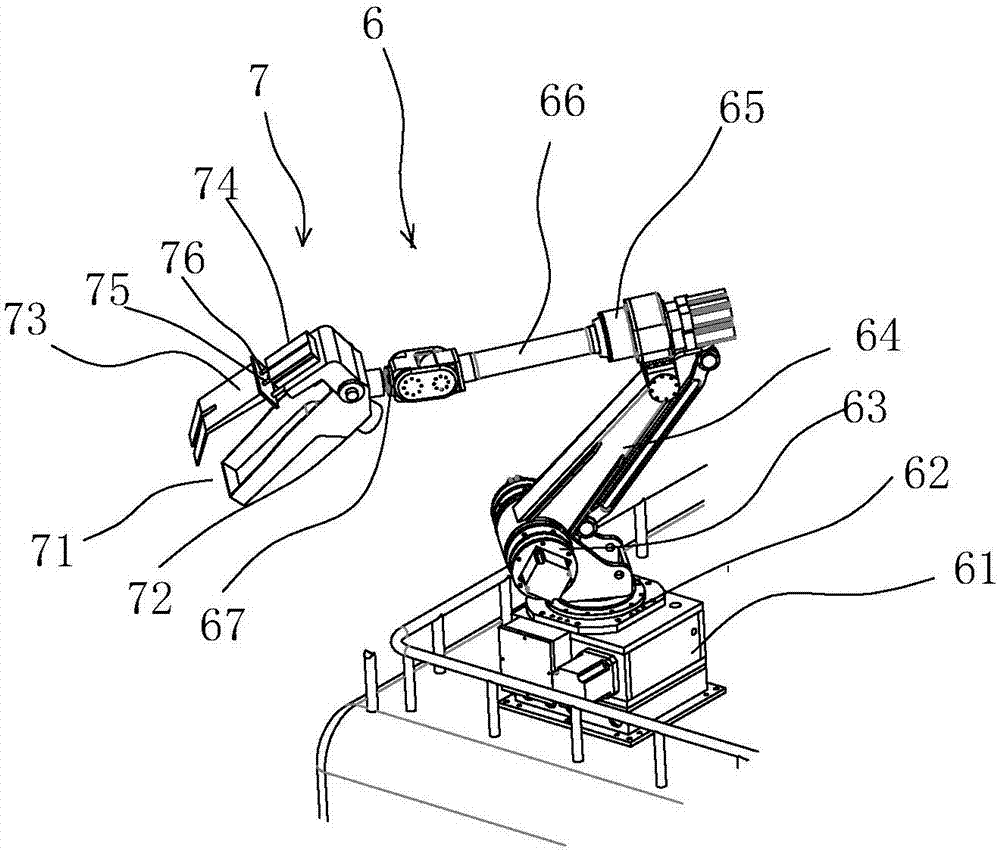

[0026] After the orange is ripe, it is yellow, and is different from the green of the leaves. The color sensor 75 determines the direction of the ripe fruit, and the distance sensor 76 determines the distance between the fruit picker 7 and the fruit. The mechanical arm 6 collects the fruit according to the color sensor 75 and the distance sensor 76. Position information, send the fruit picker 7 to the position where the fruit is picked, the fruit picker 7 picks the fruit, and the fruit enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com