Stuffing food forming equipment

A food forming and equipment technology, applied in food science, dough processing, baking, etc., can solve the problems that the dough cannot be formed into a regular shape and is easy to break, and achieves good shaping effect, smooth piercing, and good space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

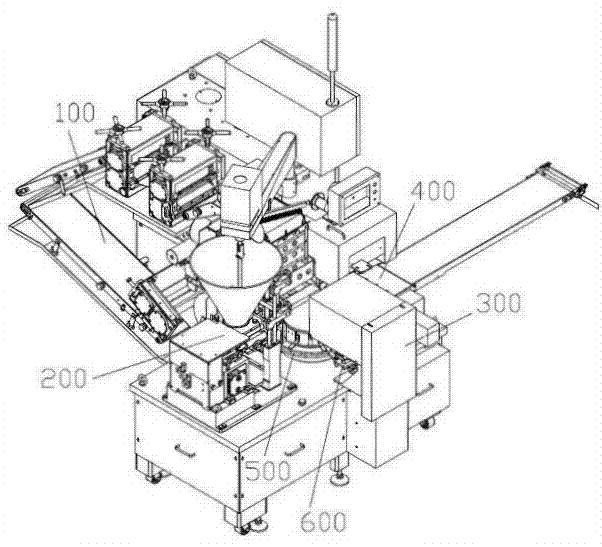

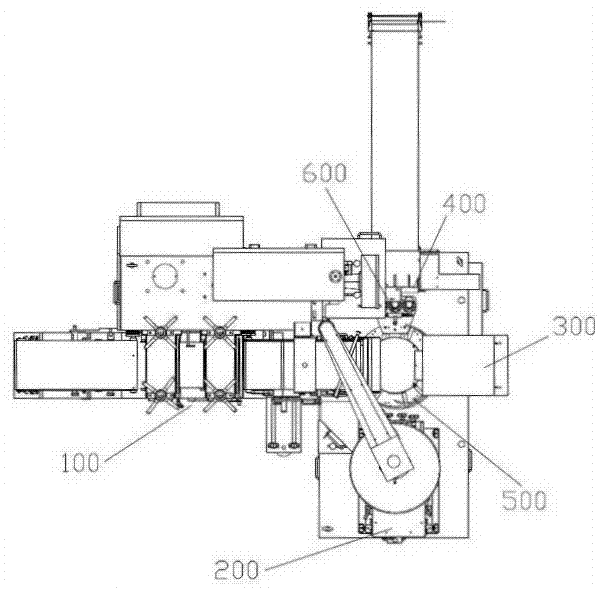

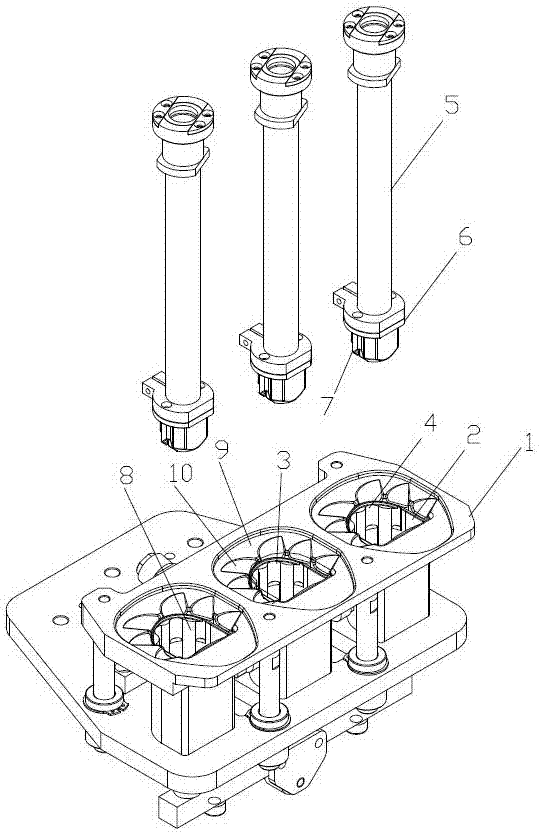

[0032] A kind of filling food forming equipment comprises a noodle supply mechanism 100, a filling mechanism 200, a forming mechanism 300 and a discharge mechanism 400, and the noodle supply mechanism 100, the filling mechanism 200, the forming mechanism 300 and the discharge mechanism 400 are distributed in sequence Around the annular station disc 500, the annular station disc 500 is provided with a molding die 600 that can move circularly around the annular station disc 500; A molding hole 3 is provided on the skin-connecting plate 1, and the mold cup 2 passes through the molding hole 3, and a semi-circular or full-arc-shaped step 9 structure is provided on the inner side wall of the upper part of the mold cup 2, where The semicircle and full arc mentioned refer to a continuous semicircle or a continuous full arc, and the arc itself is not divided, such as image 3As shown, the step is a semi-arc structure. The step 9 structure is lower than the upper edge of the mold cup 2...

Embodiment 2

[0040] A kind of filling food forming equipment comprises a noodle supply mechanism 100, a filling mechanism 200, a forming mechanism 300 and a discharge mechanism 400, and the noodle supply mechanism 100, the filling mechanism 200, the forming mechanism 300 and the discharge mechanism 400 are distributed in sequence Around the annular station disc 500, the annular station disc 500 is provided with a molding die 600 that can move circularly around the annular station disc 500; A molding hole 3 is provided on the skin-connecting plate 1, and the mold cup 2 passes through the molding hole 3, and a semi-circular or full-arc-shaped step 9 structure is provided on the inner side wall of the upper part of the mold cup 2, where Both the semicircle arc and the full circle arc mentioned refer to a continuous semicircle arc or a continuous full circle arc, and the arc itself is not divided. The step 9 structure is lower than the upper edge of the mold cup 2, so it is called the step 9 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com