Novel hydrogen/oxygen separating device

A separation device and a new type of technology, applied in separation methods, dispersed particle separation, gas treatment, etc., can solve problems such as large equipment volume, and achieve the effects of improving gas-liquid separation efficiency, reducing volume, and reducing space occupancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

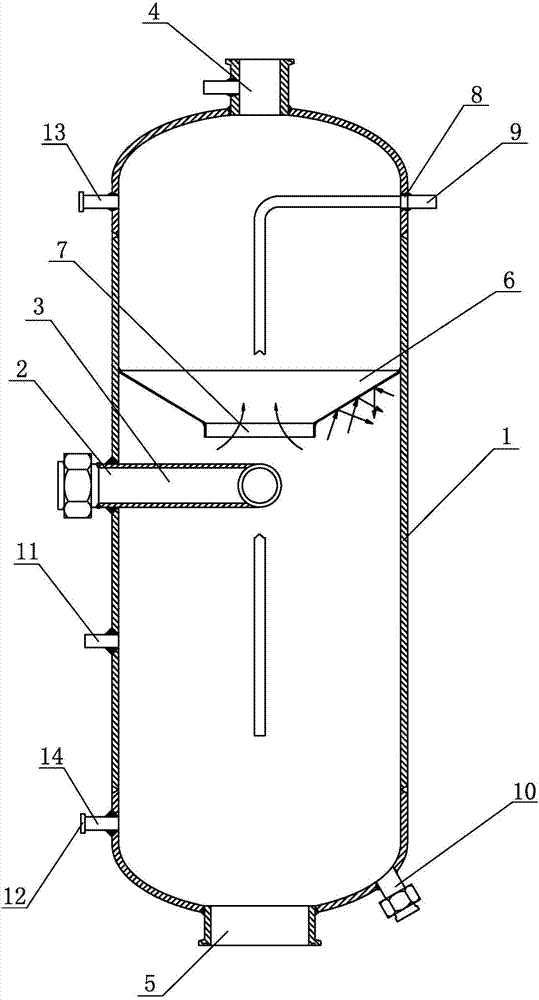

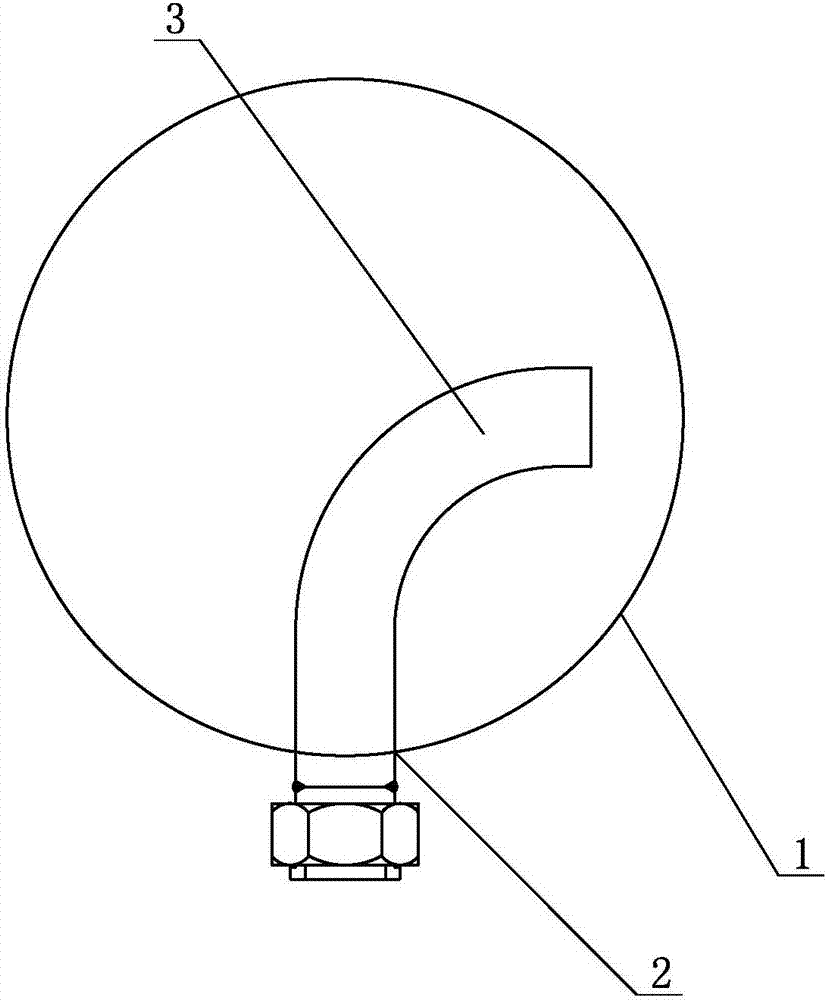

[0020] Embodiment one: see figure 1 , 2 As shown, a novel hydrogen / oxygen separation device includes a tank body 1, the middle part of the tank body 1 is provided with an air inlet 2, and the air inlet 2 is provided with an air inlet pipe 3, and one end of the air inlet pipe 3 is It is arranged on the outside of the tank body 1, and the other end is inserted into the inside of the tank body 1; the top of the tank body 1 is provided with an air outlet 4, and the bottom is provided with a liquid outlet port 5; the middle part of the tank body 1 is also provided with a An inverted conical baffle 6, the center of the inverted conical baffle 6 is provided with an air hole 7, the outer edge of the inverted conical baffle 6 is connected to the inner wall of the tank body 1, and the inverted The conical baffle 6 is arranged above the intake pipe 3 .

[0021] In the previous structure, oxygen or hydrogen with water enters from the middle of the tank, and then using the difference in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com