High-precision no-woven cloth production detection and post treatment equipment

A technology of production detection and post-processing, applied in the device and coating of the surface coating liquid, can solve the problem of lack of unidirectional cloth detection and timely replenishment of glue, reducing the strength of unidirectional cloth, and defective glue, etc. Avoid unstable quality, ensure accuracy, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

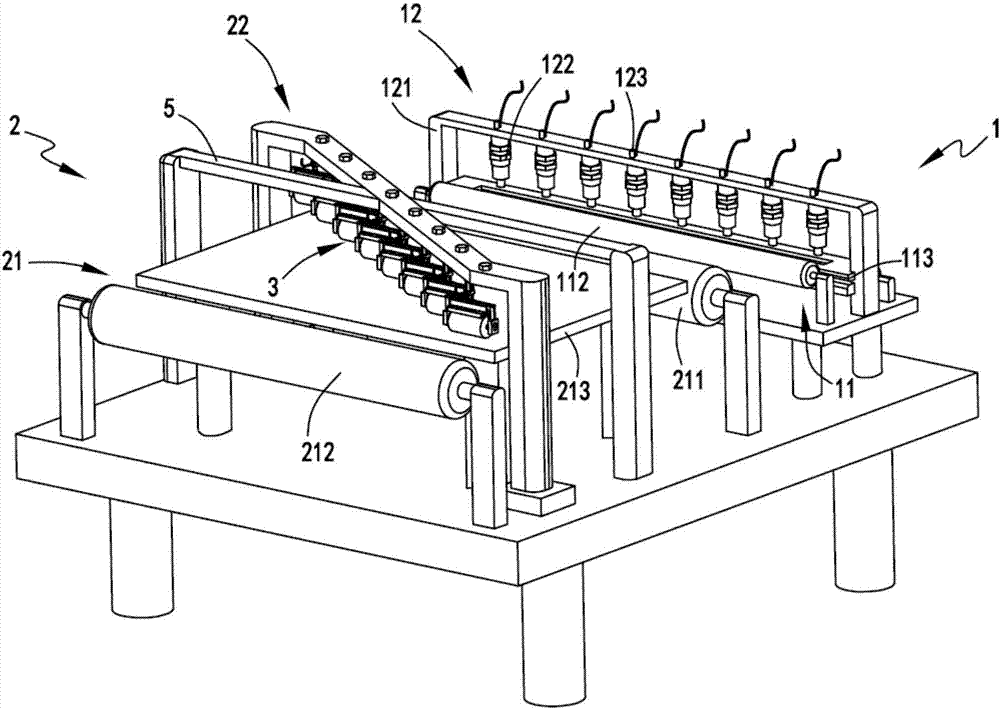

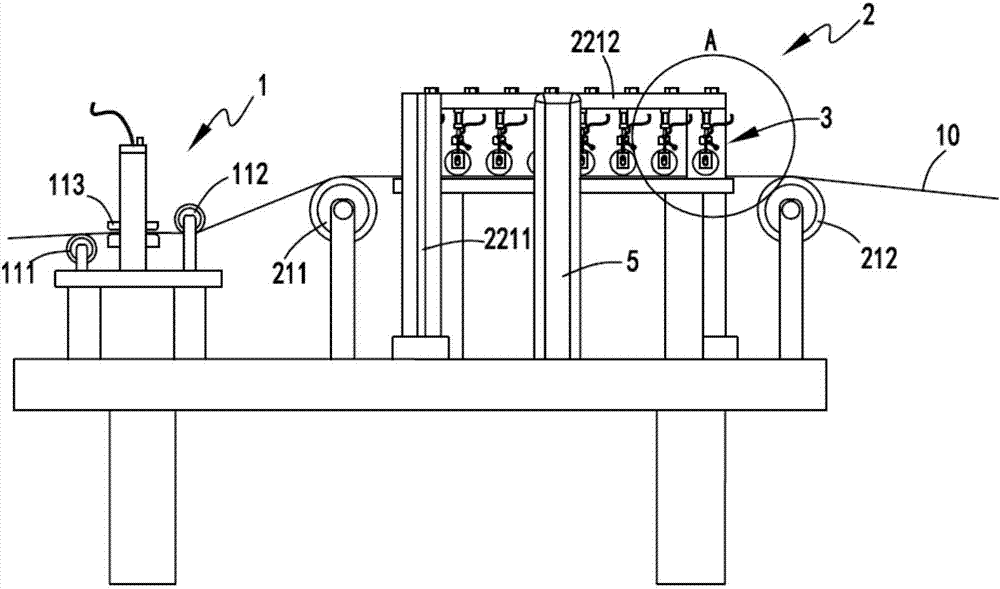

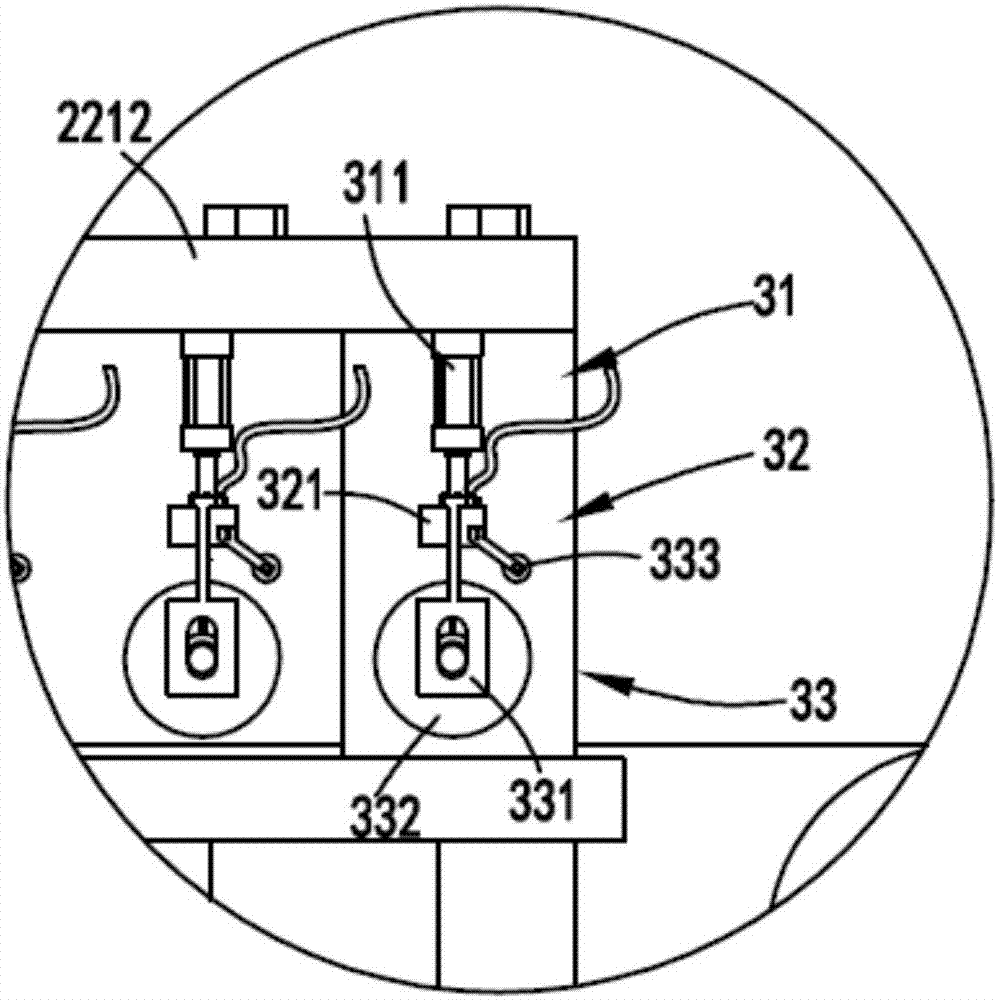

[0036] figure 1 It is a schematic diagram of the structure of high-precision non-woven fabric production testing and post-processing equipment, figure 2 It is a schematic diagram of the front view of the high-precision non-woven fabric production testing and post-processing equipment, image 3 It is a partial structural diagram of the glue replenishing mechanism, Figure 4 It is a schematic diagram of the non-working state of the gluing device, Figure 5 It is a schematic diagram of the relative position of the cover and the discharge hole when the gluing device is not working, Figure 6 It is a schematic diagram of the working state of the gluing device, Figure 7 It is a schematic diagram of the relative position of the cover and the discharge hole when the gluing device is working, Figure 8 It is a schematic diagram of the structure of the discharge part and the glue roller, Figure 9 is a schematic diagram of the structure of the rubber box, Figure 10 Schematic di...

Embodiment 2

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: further, the end of the discharge hole 3212 close to the inside of the rubber material box 321 and the lower end of the cover 3222 are provided with chamfers, and the lower end of the cover 3222 The end face cooperates with the upper end face of the discharge hole 3212 .

[0051] The end of the discharge hole 3212 close to the inside of the rubber material box 321 and the lower end of the cover 3222 are provided with chamfers, so that when the glue is not replenished, the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com