Vibrating table for cement component

A vibrating table and component technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of increasing the vibration effect of the vibration plate, increasing the vibration effect, reducing the vibration effect, etc., to reduce the mutual interference of dual-frequency vibration, increase the vibration effect and weaken it , to eliminate the effect of vibration offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

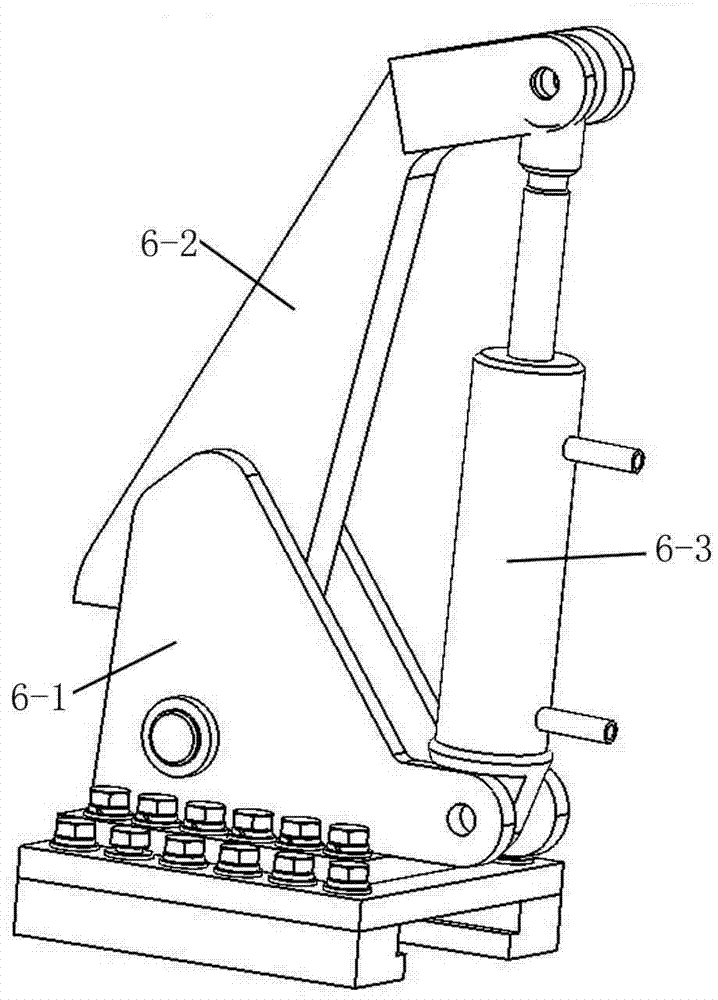

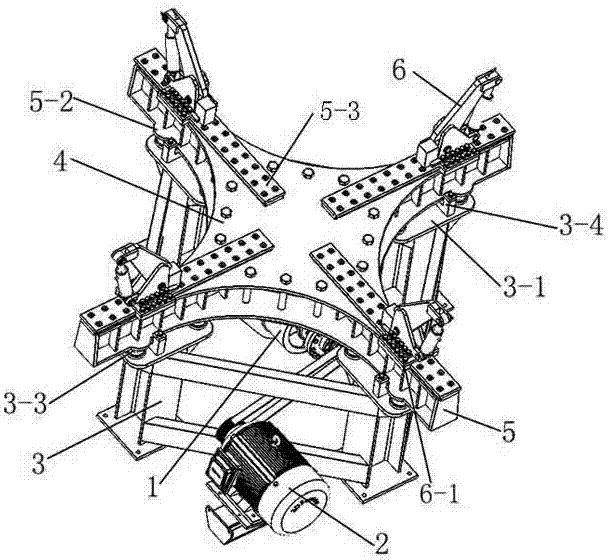

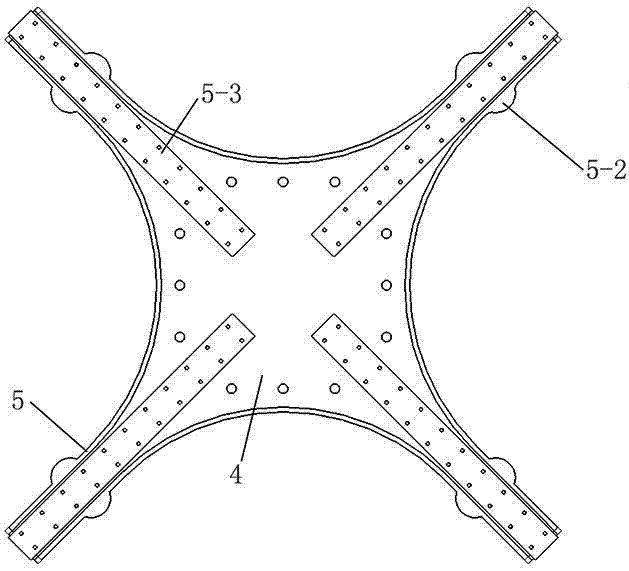

[0017] Such as Figure 1-5 As shown, a cement component vibration table includes 1 vibrator and 2 drive motors that drive the vibrator, and also includes 3 fixed seats and 4 vibration plates that are independent of each other. The top surface of the 4 vibration plates is used for placing non-fixed connection on The vibrating cement component on the vibrating plate, the 1 vibrator is fixedly mounted on the bottom surface of the 4 vibrating plate, the side ends of the 4 vibrating plate are provided with at least three groups of 5 extension brackets, and the bottom surface of the 5 extension brackets is provided with 5 -1 spring slot, the 5 extension bracket at the side end of the 5-1 spring slot is provided with a 5-2 limit convex seat; the 3 fixed seat below the 5-1 spring slot is equipped with a 3-1 bearing Plate, the 3-1 bearing plate is provided with a 3-2 spring card slot two corresponding to the 5-1 spring card slot, and the 5-1 spring card slot and the 3-2 spring card slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com