Total element vector propulsion system

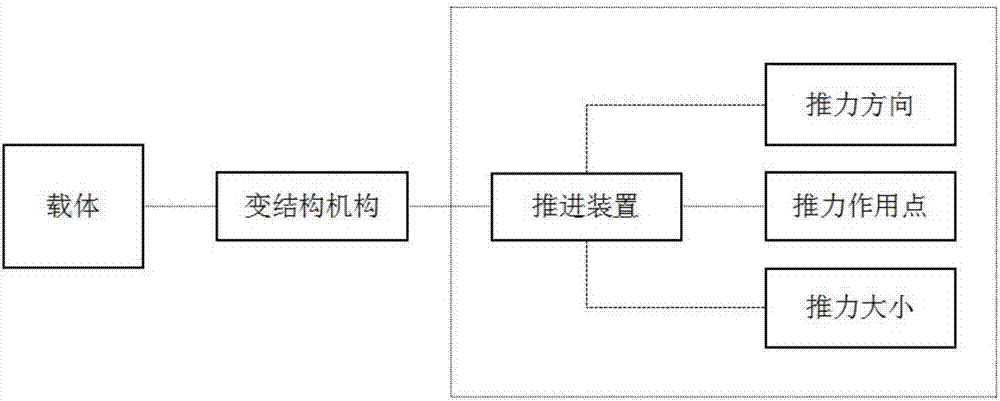

A vector propulsion and all-element technology, which is applied to aircraft parts, aircraft control, flight direction control, etc., can solve the problem of reducing dependence, and achieve the effect of wide application range, flexible control, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

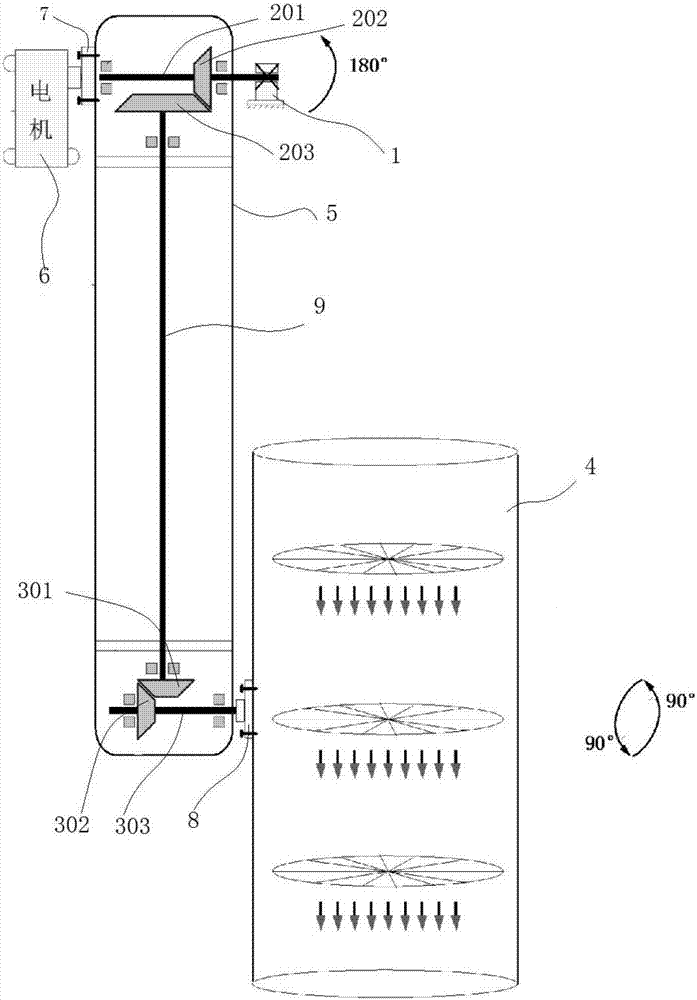

[0043] see image 3 Shown, the mode that propulsion device 4 cooperates with a group of structure-changing mechanisms.

[0044] The variable structure mechanism includes a fixed seat 1; the fixed seat 1 is fixed with a driving device 6; the output end of the driving device 6 is fixed with a first connector 7; one end of the swing arm is fixed on the first connector 7, and the swing arm is driven by the drive device 6 Swing; the other end of the swing arm is provided with a moving shaft 303; during the swinging process of the swing arm, the moving shaft 303 is rotating at the same time; the fixing base 1 adopts a U-shaped groove plate metal structure.

[0045]The swing arm comprises an arm bar 5, and a first gear box 2 and a second gear box 3 are respectively fixed at both ends of the arm bar 5; the driving device 6 drives the swing arm to swing; the first gear box 2 at one end of the swing arm is provided with a first gear The second gear box 3 at the other end of the swing a...

Embodiment 2

[0057] like Image 6 Shown, the mode that propulsion device 4 cooperates with a group of structure-changing mechanisms.

[0058] The variable structure mechanism includes a fixed seat 1; the fixed seat 1 is fixed with a driving device 6; the output end of the driving device 6 is fixed with a first connector 7; one end of the swing arm is fixed on the first connector 7, and the swing arm is driven by the drive device 6 Swing; the other end of the swing arm is provided with a moving shaft 303; the rotating mechanism and the swing arm are displaced synchronously; the fixing seat 1 adopts a U-shaped groove plate metal structure; the variable structure mechanism is fixed on the carrier through the fixing seat 1.

[0059] The swing arm includes an arm rod 5, and a first gear box 2 and a second gear box 3 are respectively fixed at both ends of the arm rod 5; a driving device 6 drives the swing arm to swing;

[0060] The first gear box 2 includes a fixed shaft 201; the first gear box...

Embodiment 3

[0065] like Figure 7 Shown, the mode that propulsion device 4 cooperates with two groups of structure-changing mechanisms. Two variable structure mechanisms are symmetrically arranged on the periphery of the propulsion device 4, and the thrust direction and thrust action point of the propulsion device 4 are controlled by two sets of variable structure mechanisms, which have good structural stability. According to the above structure, the variable structure mechanism includes a fixed seat 1; the fixed seat 1 is fixed with a driving device 6; the output end of the driving device 6 is fixed with a first connector 7; one end of the swing arm is fixed on the first connector 7, and the drive device 6. Drive the swing arm to swing; the other end of the swing arm is provided with a moving shaft 303; during the swinging process of the swing arm, the moving shaft 303 is rotating at the same time; the fixing seat 1 adopts a U-shaped groove plate metal structure.

[0066] The swing arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com