Copper tube-assisted cathodic plasma electrolysis method and device for preparing coating

A cathode plasma and plasma arc technology, which is applied in the direction of electrolytic inorganic material coating, electrolytic components, electrolytic process, etc., can solve the problems of complex process, high cost, uneven coating, etc., and achieve simple device structure, low device cost, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

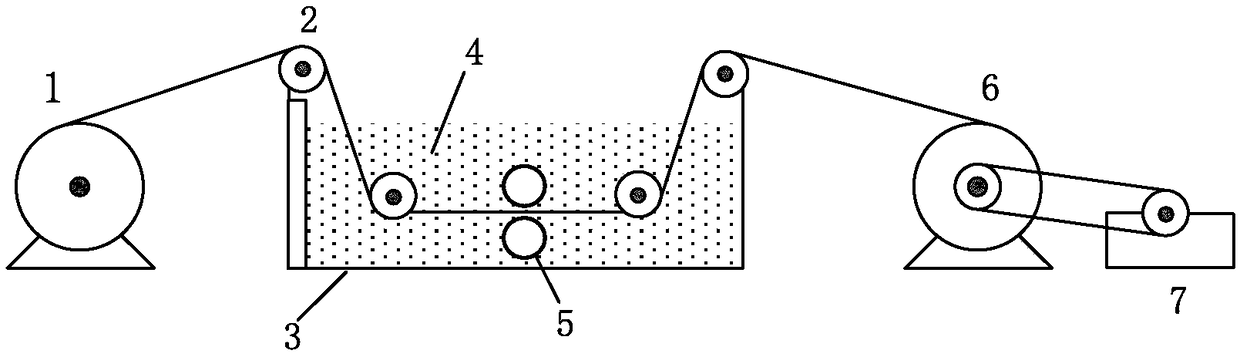

[0033] The specific steps of preparing the coating by cathode plasma electrolysis assisted by copper tube are as follows:

[0034] (1) Sodium metaaluminate is dissolved in deionized water, and an electrolyte solution 4 with a concentration of 30 g / L is prepared; the prepared electrolyte solution 4 is added to the reaction vessel 3;

[0035] (2) Immerse the parts 5 and the high-purity graphite plate as the positive electrode into the electrolytic solution 4 to generate the plasma arc region, and the negative electrode and the positive electrode are connected to the high-frequency direct current power supply respectively; Apply 160V voltage to the positive electrode to form a stable plasma arc area;

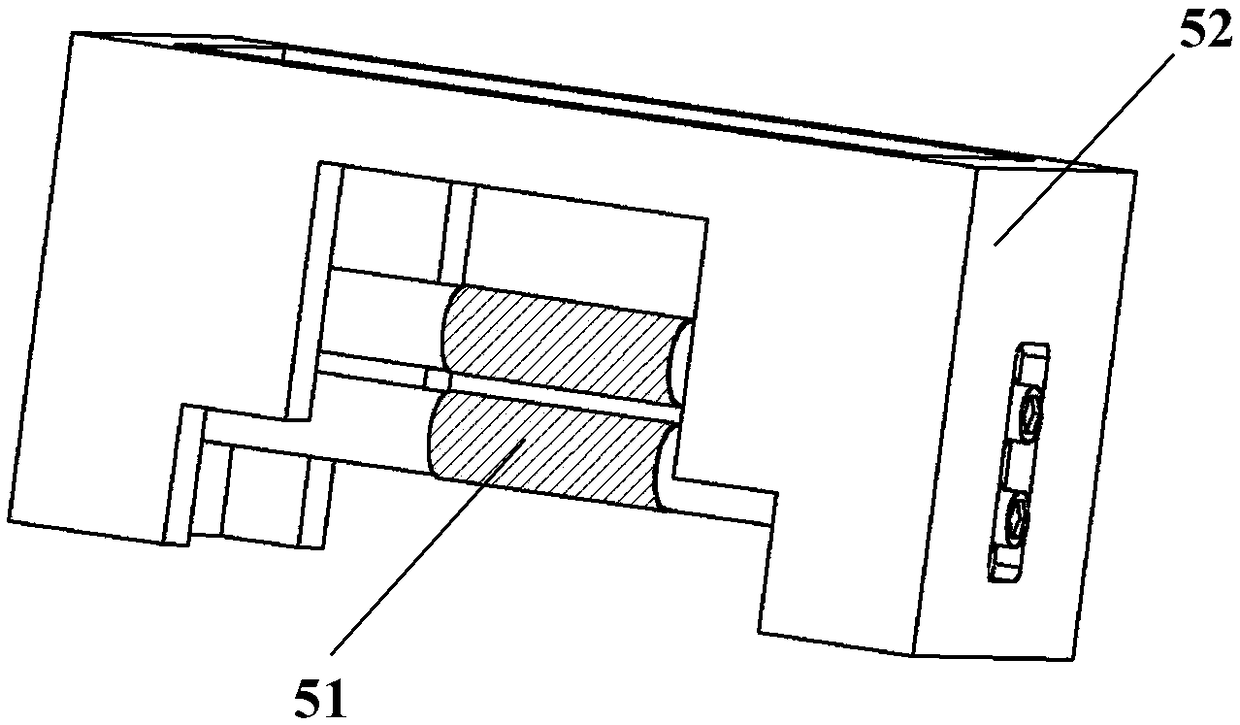

[0036] (3) Driven by the motor 7, the pay-off machine 1 releases the carbon fiber cloth, and the carbon fiber cloth is introduced into the electrolyte 4 through a crimping wheel 2 on the top of the side wall of the reaction vessel 3, and then the carbon fiber cloth is immersed in t...

Embodiment 2

[0039]The specific steps of preparing the coating by cathode plasma electrolysis assisted by copper tube are as follows:

[0040] (1) Sodium silicate is dissolved in deionized water, and an electrolyte solution 4 with a concentration of 50 g / L is prepared; the prepared electrolyte solution 4 is added to the reaction vessel 3;

[0041] (2) immerse the parts 5 and the high-purity graphite plate as the anode electrode into the electrolytic solution 4 to produce the plasma arc region, and the cathode electrode and the anode electrode are connected to the high-frequency direct current power supply respectively; The anode electrode applies 360V voltage to form a stable plasma arc area;

[0042] (3) Driven by the motor 7, the pay-off machine 1 releases the carbon fiber cloth, and the carbon fiber cloth is introduced into the electrolyte 4 through a crimping wheel 2 on the top of the side wall of the reaction vessel 3, and then the carbon fiber cloth is immersed in the electrolyte 4 ...

Embodiment 3

[0045] The specific steps of preparing the coating by cathode plasma electrolysis assisted by copper tube are as follows:

[0046] (1) Aluminum nitrate is dissolved in deionized water, and an electrolyte 4 with a concentration of 60g / L is prepared; the prepared electrolyte 4 is added to the reaction vessel 3;

[0047] (2) immerse the parts 5 and the high-purity graphite plate as the anode electrode into the electrolytic solution 4 to produce the plasma arc region, and the cathode electrode and the anode electrode are connected to the high-frequency direct current power supply respectively; The anode electrode applies 260V voltage to form a stable plasma arc area;

[0048] (3) Driven by the motor 7, the pay-off machine 1 releases the carbon fiber cloth, and the carbon fiber cloth is introduced into the electrolyte 4 through a crimping wheel 2 on the top of the side wall of the reaction vessel 3, and then the carbon fiber cloth is immersed in the electrolyte 4 The two crimping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap