Jet-flow control structure for overflow surface of high dam

A technology of jet control and overflow surface, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of strong downstream backflow, downstream riverbed deformation, serious problems, etc., and achieve stable water flow shape, slight riverbed scour, and sufficient energy dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

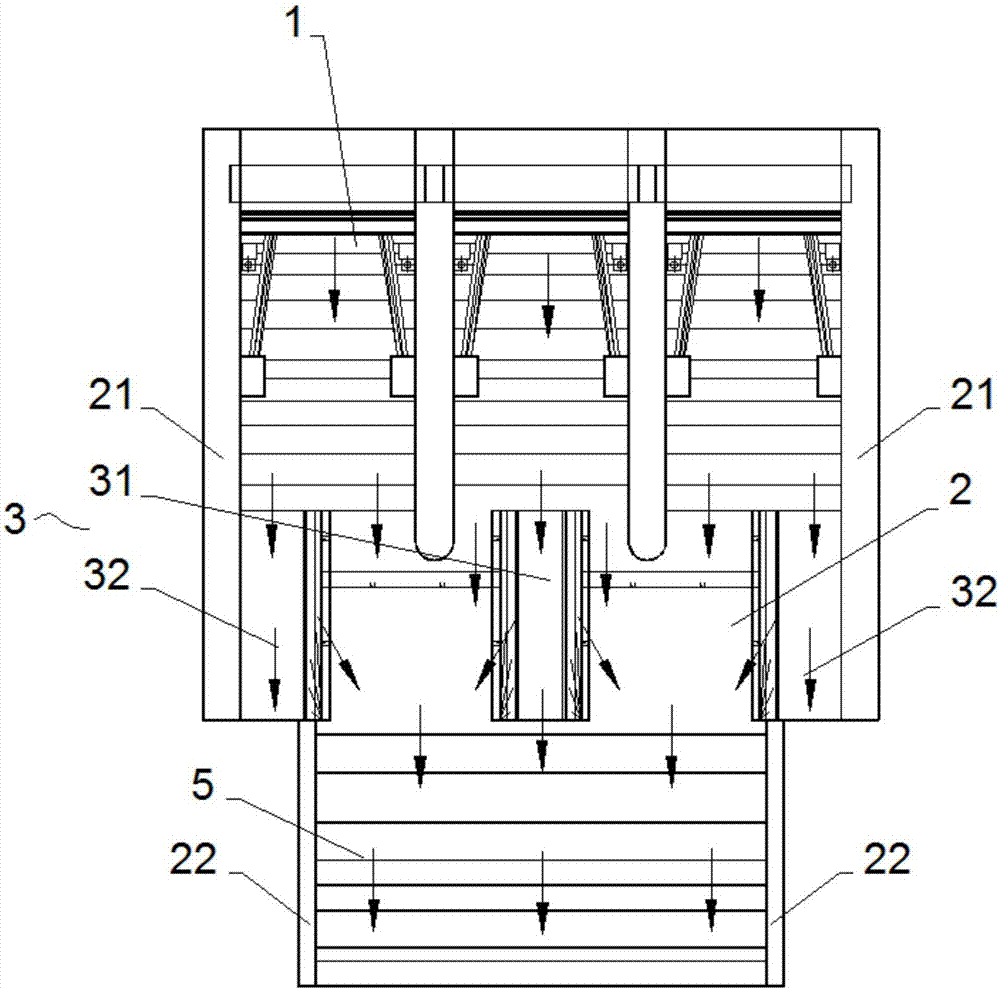

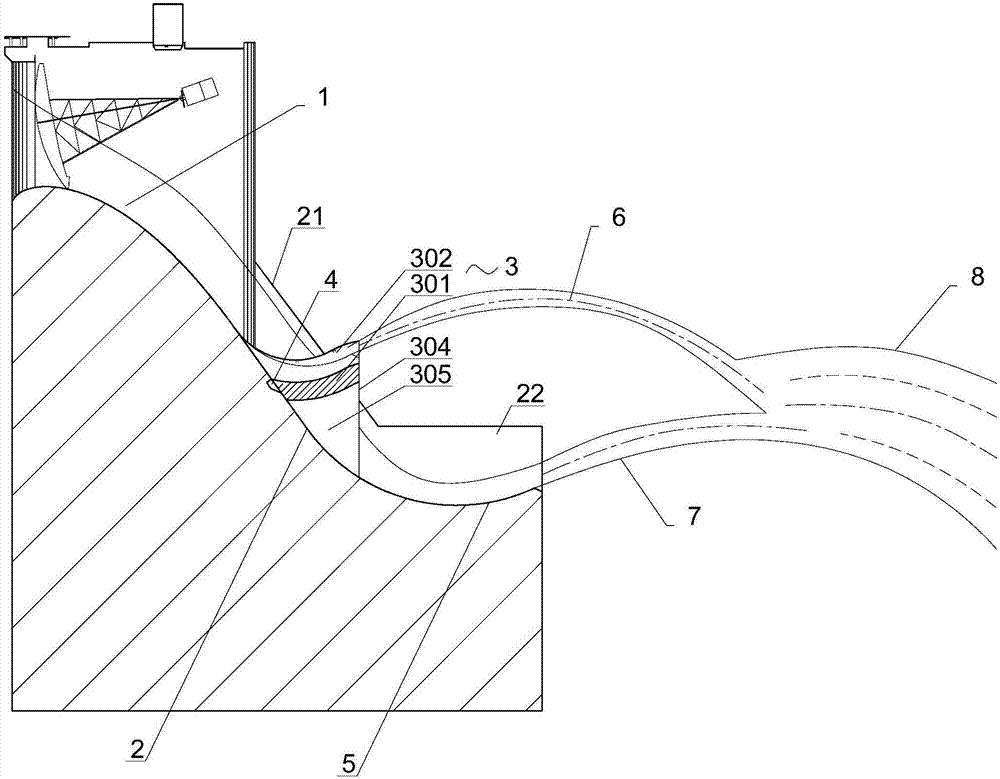

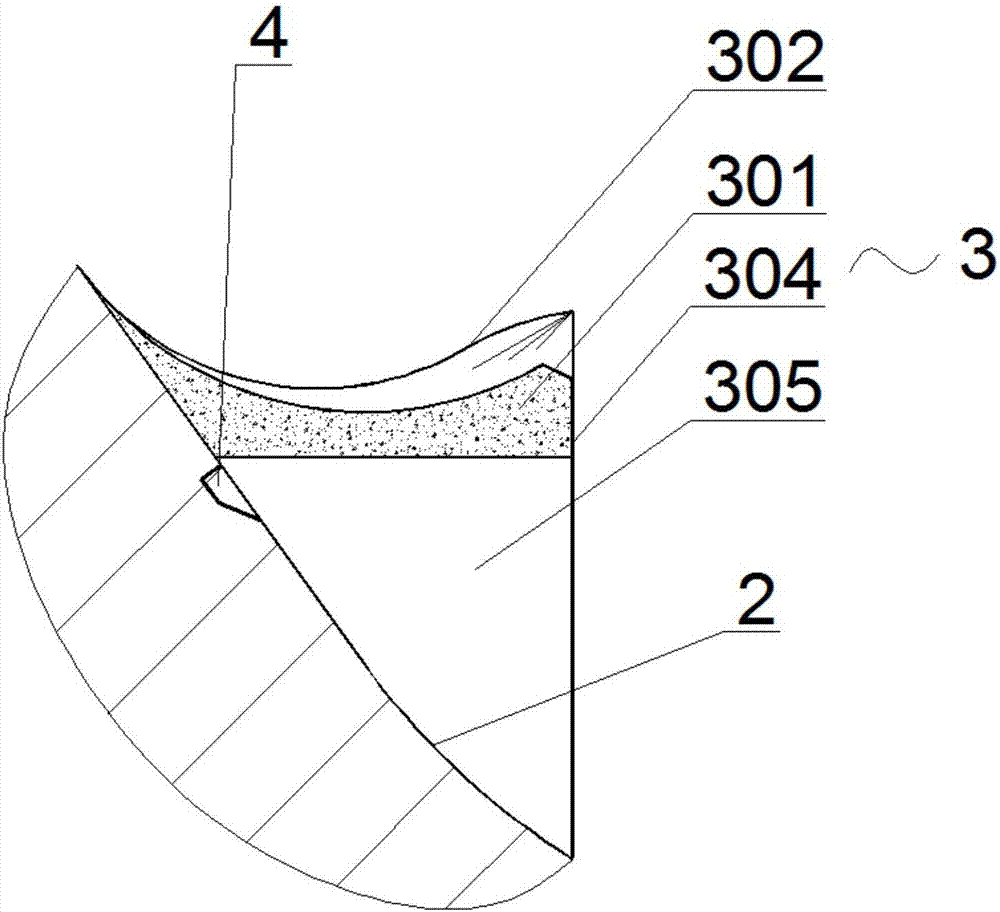

[0033] see Figure 1 to Figure 4 As shown, the high dam overflow surface jet flow control structure of the present invention includes an overflow gate hole 1 arranged on the dam body, and the end of the WES curve of the dam body weir surface below the overflow gate hole 1 joins the steep groove section 2, and the steep groove The end of the section 2 is provided with a continuous ridge 5, and the steep trough section 2 is provided with an overflow surface ridge 3 capable of partitioning the water flow, and the overflow surface ridge 3 includes an intermediate overflow surface ridge 31 and edge overflow surface pick ridge 32, the middle overflow surface pick ridge 31 is located in the center of the steep groove section 2, the outer edge of the edge overflow surface pick ridge 32 is respectively connected with the steep groove section 2 The upper pier 21 on the side is correspondingly connected, and the overflow surface ridge 3 is provided with an arc-shaped projection bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com