Hydraulic design method for turned-slope type hydraulic jump stilling basin

A technology of pool water and energy dissipation, applied in water conservancy engineering, marine engineering, coastline protection, etc., can solve problems such as infeasible auxiliary energy dissipation workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] If known: the height difference P between the crest of the weir and the bottom of the pool d =23m; single width flow q=212m 3 / s, the water level upstream of the weir is 362.2m, the water level downstream of the weir is 353.4m, and the water level difference between the upstream and downstream of the weir is ΔZ=8.8m, which is substituted into the formula

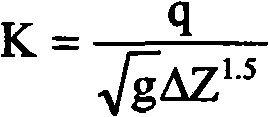

[0035] K = q g ΔZ 1.5

[0036] K = 23 9.8 × 8.8 1.5 ≈ 2.59

[0037] Because the value range of K is 0.5~3.0, bring it into the following formula:

[0038] L c P d = 0.93 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com