Automated robot spraying production line for large wind power products

A production line and robot technology, applied in spray booths, spray devices, etc., can solve the problems of affecting the cleanliness of the paint surface, inconvenient operation, and serious injury to operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

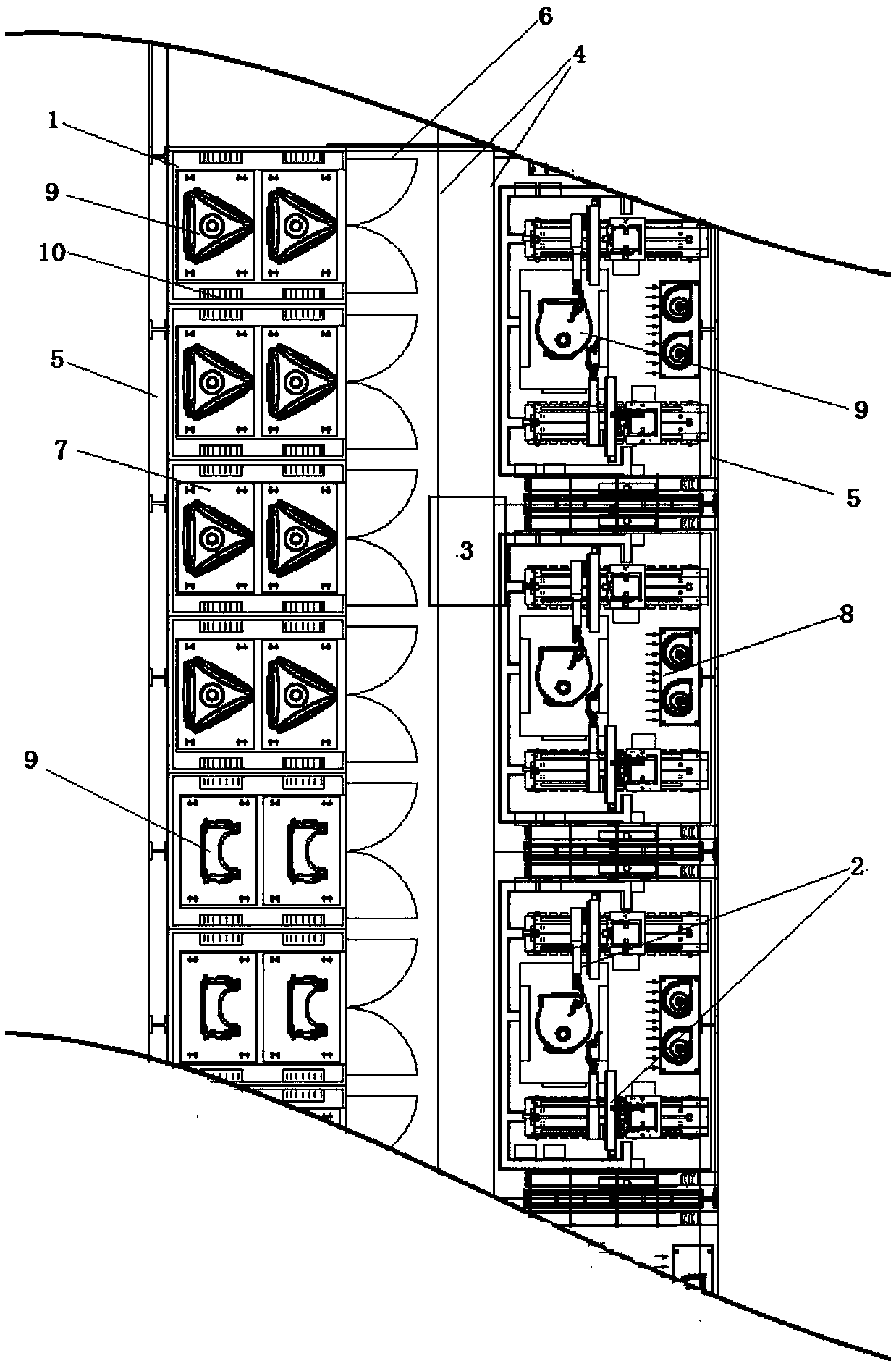

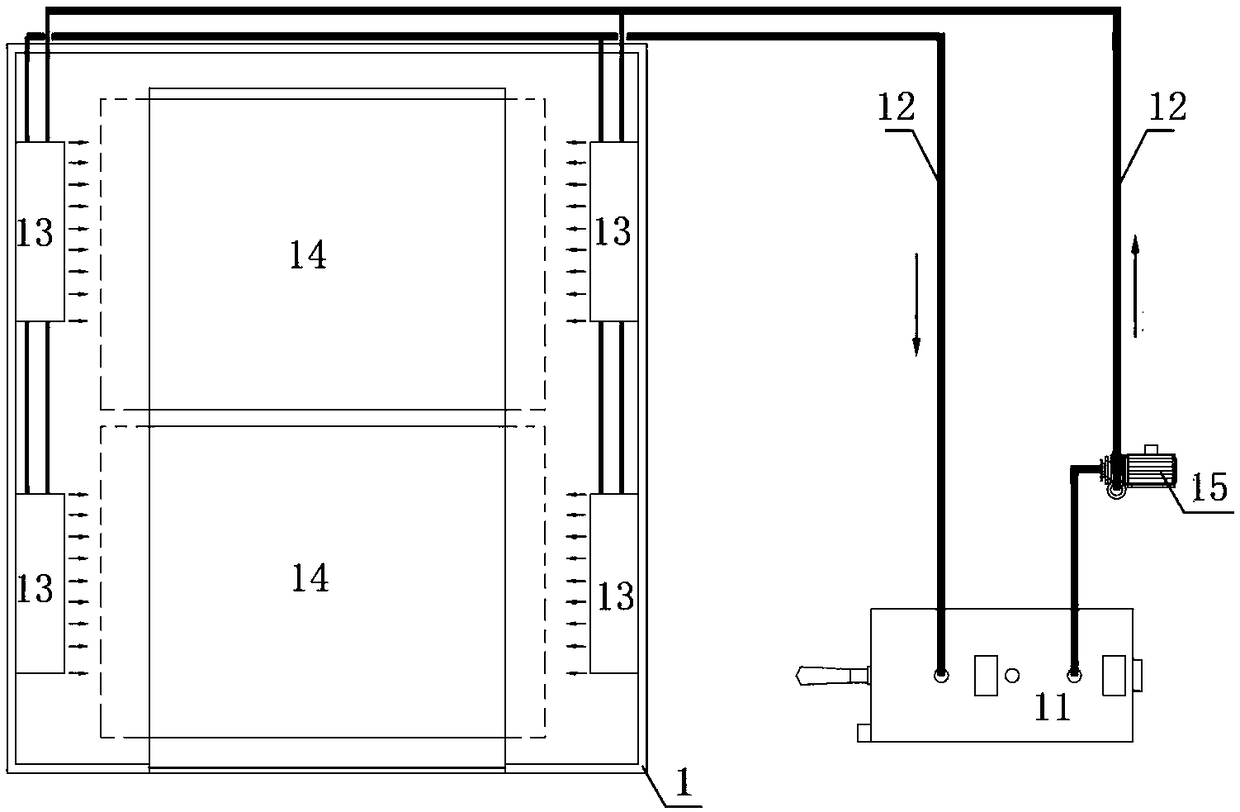

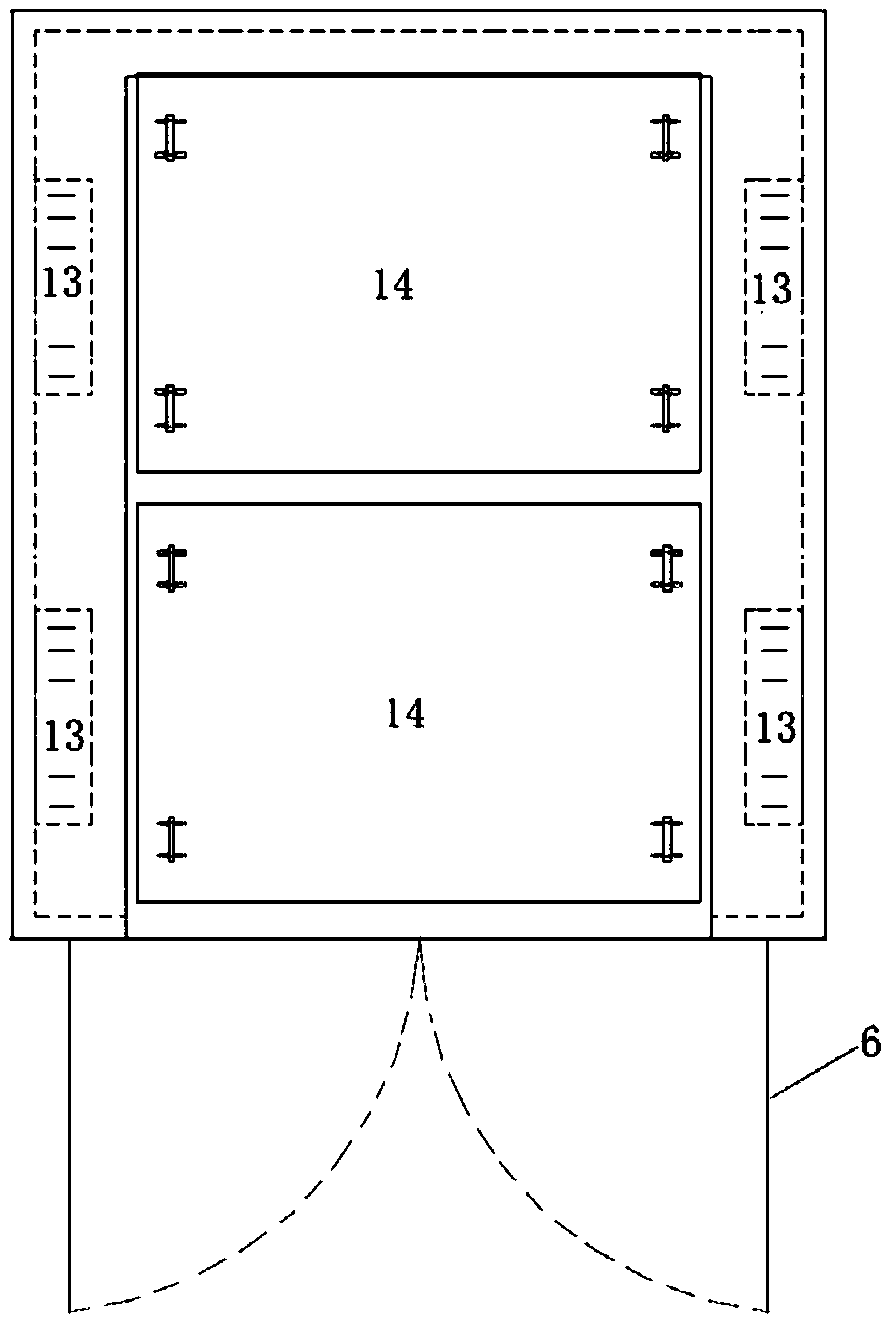

[0110] Introduce this technical scheme below in conjunction with accompanying drawing:

[0111] For example, the workpiece in the attached picture is a certain type of wind turbine nacelle component, its shape is irregular and complicated, the size is larger and the widest part reaches more than 5 meters, and the weight of a single blank reaches about 50 tons.

[0112] Such as figure 1 , an automated robot spraying production line for large-scale wind power products, including workshops, spraying stations, painting stations, transfer equipment and on-site air purification systems; there are one or more spraying stations and painting stations; spraying workers The station and the painting station are respectively located on the left and right sides of the factory building; the painting station is equipped with an independent paint booth; the spraying station is equipped with spraying equipment; the transfer equipment includes driving and DC electric trolleys; The ground track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com