Portable bending tool and using method thereof

A portable, tool-based technology, applied in the installation of cable installation devices, electrical components, cables, etc., can solve problems such as laborious, inaccurate bending, and cable slipping out, and achieve low production costs, simple connection relationships, and facilitate disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

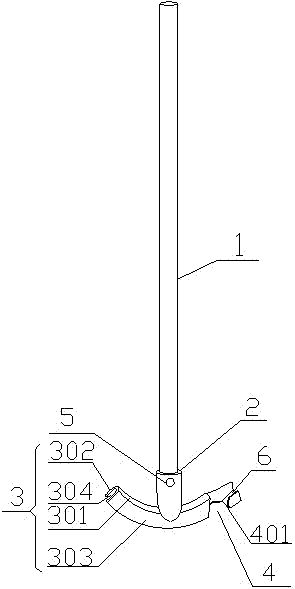

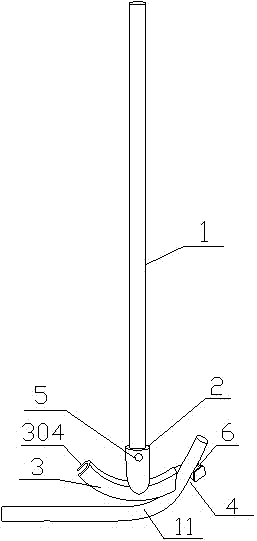

Embodiment 1

[0034] refer to figure 1 , a portable bending tool, including a rod 1 and a bending assembly, the bending assembly includes a connector 2, a guide groove body 3 and a bayonet 4, one end of the connector is connected to the rod, and the other end is connected to the Described guide groove body, described guide groove body comprises a bottom surface 301 and first side 302 and second side 303 integrally connected with this bottom surface, constitutes the groove one 304 that limits the object to be held and bent, and described guide groove body is in the form of Arc-shaped, one end of the guide groove body is provided with the bayonet socket, so that the object to be bent passes through the bayonet socket and abuts against the edge of the bayonet socket.

[0035] In the present invention, the connecting head and one end of the rod are fixed by a screw 5 .

[0036] In the present invention, the rod part is preferably a cylindrical steel pipe. The bending assembly is preferably ma...

Embodiment 2

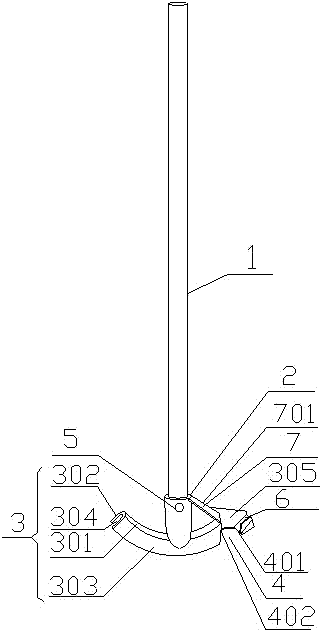

[0042] refer to image 3 , the portable bending tool described in this embodiment is an improvement on the basis of Embodiment 1, wherein:

[0043] A reinforcing rib 7 is provided between the guide groove body and the connecting head, one end of the reinforcing rib is connected to the second edge 402 of the bayonet socket, and the other end is connected to the upper part of the connecting head.

[0044] A reinforcing rib is provided to enhance the connection strength between the rod and the bending assembly, enhance the force application stability of the rod, share part of the force of the bending assembly, and improve the service life of the bending assembly.

[0045] The first side 701 of the rib is connected to the extension surface 305 of the first side 302 of the guide groove body.

[0046] The extension surface 305 cooperates with the reinforcing rib to further improve the connection strength between the rod and the bending assembly, and after the object to be bent is s...

Embodiment 3

[0048] refer to Figure 4 , the portable bending tool described in this embodiment is an improvement on the basis of Embodiment 2, wherein:

[0049] The rod portion is provided with a length scale line 8 .

[0050] During on-site construction, it is often necessary to use a ruler to measure, but the staff may forget to carry the ruler. At this time, they can use a portable bending tool to measure the size, record the size after measurement, and select the steel pipe for bending. For the bending operation of steel pipe members, if you want to get a very beautiful bending effect, you can pre-install sand in the steel pipe, seal the two ends of the steel pipe, and then insert the bending assembly to perform the bending bit by bit. Beautiful, there is no place to wrinkle at the bend.

[0051] The second side of the guide groove body is provided with arc scale lines 9 .

[0052] In this way, when performing the bending operation on site, it is convenient for the staff to compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com