Quick-connection type water braid

A quick-connecting and water-braiding technology, which is applied to drilling equipment, earthwork drilling, and drill pipes, can solve the problems of affecting the life of water braids, reducing drilling efficiency, and reducing sealing effects, so as to improve drilling and running-in Efficiency, improving drilling efficiency, and facilitating disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

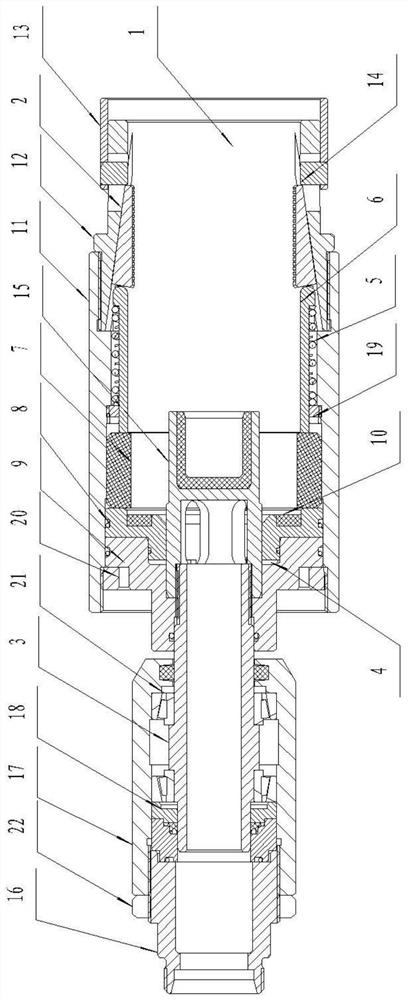

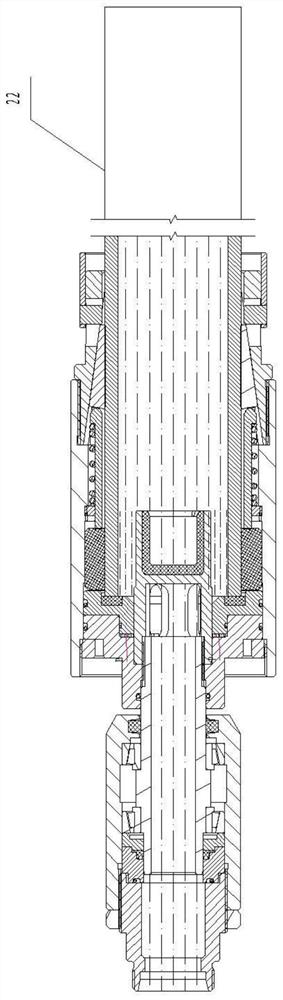

[0021] As shown in the figure: The fast-consequent aquatic braid of the present embodiment includes an interconnected water pipe connection portion and a drill rod connecting portion having the end portion of the drill rod 22 to be sealed and sealed with the end. A cartridge device is provided in the quick-fitting chamber, which is configured to automatically hold the drill rod and the drill pipe connection portion. Combine figure 1 As shown, the water pipe connection is located on the left side. The drill pipe connecting portion is located on the right side, and the two are connected to each other, and the water pipe connection portion has a threaded interface for connection with the water pipe or trachea, and the drill rod connecting portion has a card Pick up the device, combined figure 2 As shown, when the left end of the drill rod is mounted in the fast chamber, the drill rod is automatically connected to the drill rod connecting portion by the snap device, so that the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com