Novel buffering wheel structure

A technology of wheel structure and buffer mechanism, applied in casters, wheels, transportation and packaging, etc., can solve the problems of no buffer function, poor height adjustment performance, no brake system, etc., and achieve the effect of easy adjustment of the moving direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

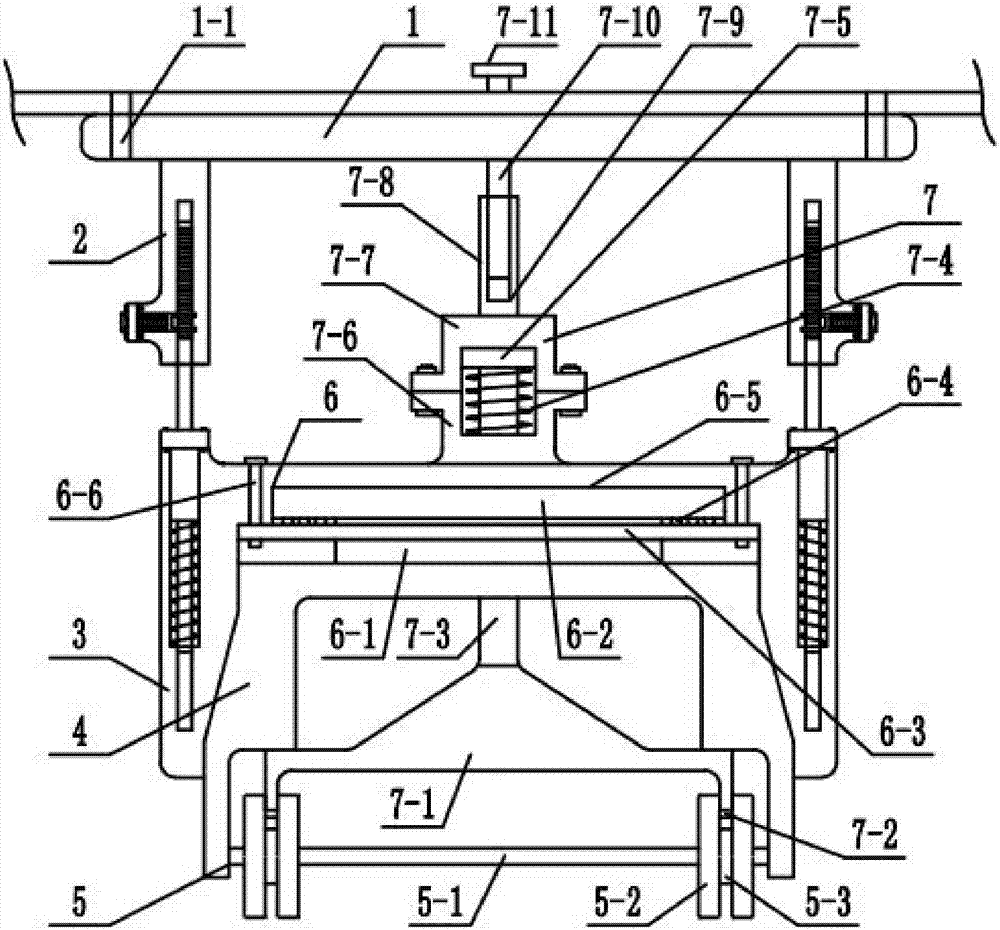

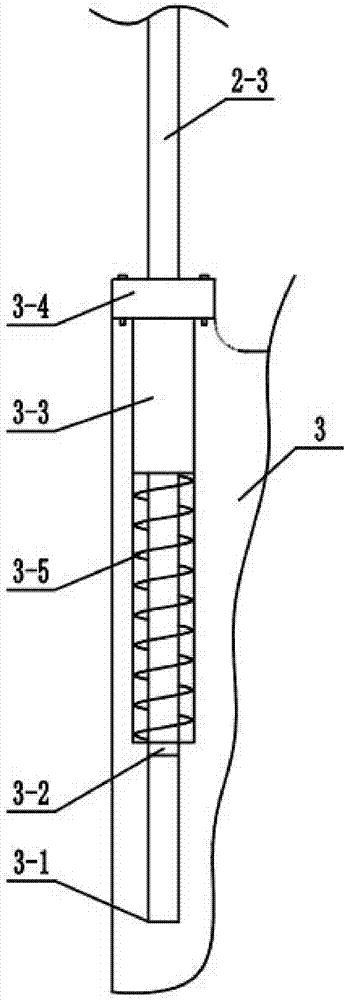

[0031] Combine below figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 To illustrate this embodiment, the present invention relates to a wheel structure, more specifically a new type of buffer wheel structure, including a fixed plate 1, an adjustment mechanism 2, a buffer mechanism 3, a moving device frame 4, a moving device 5, and a rotating mechanism 6 and brake mechanism 7, the height of the wheel can be adjusted, has a cushioning effect, the direction of movement is easy to adjust, has a brake function, and can be installed on multiple tools to replace ordinary wheels.

[0032] The fixed plate 1 is provided with a through hole 1-1, and there are four through holes 1-1, which run through the fixed plate 1 and are evenly distributed on the edge of the fixed plate 1, and the screws can pass through the through hole 1-1 to make the wheel The structure is fixed on devices such as pulleys.

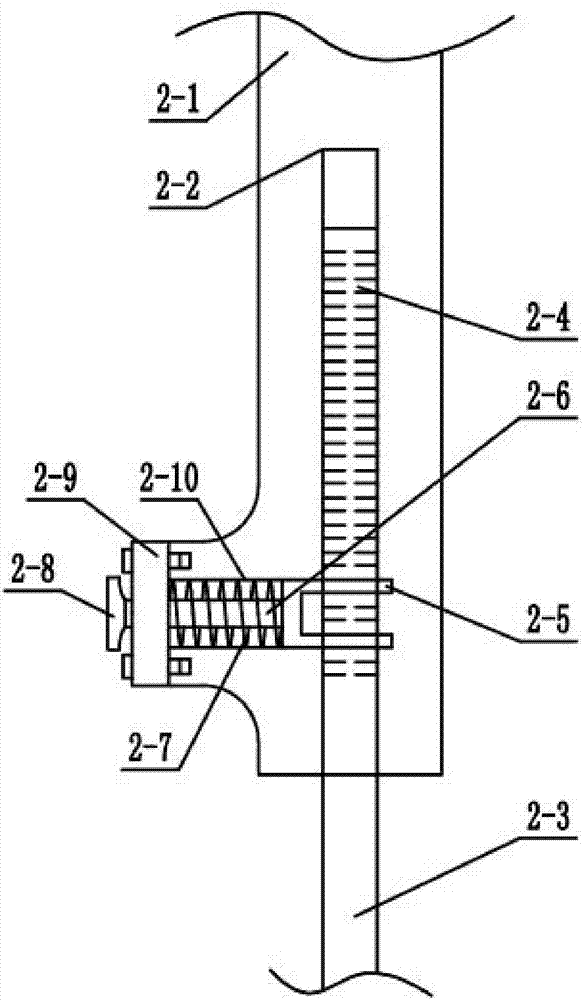

[0033] Adjusting mechanism 2 comprises sleeve rod 2-1, blind hole 2-2, supp...

specific Embodiment approach 2

[0040] Combine below figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 This embodiment will be described. This embodiment will further describe Embodiment 1. The material of the support rod 2-3 is stainless steel. Stainless steel has high strength, strong bearing capacity, and does not rust, and always maintains a good appearance.

specific Embodiment approach 3

[0042] Combine below figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Describe this embodiment mode, this embodiment mode will further explain Embodiment 1, the described insertion body 2-5, straight bar 2-6, spring 2-7, pull plate 2-8, cover plate 2-9 and Holes 2-10 share the center line, good stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com