Device For Separating And Conveying Of Piece Goods

A technology for bulk materials and loading containers, which is applied in the direction of conveying bulk materials, conveyors, conveyor objects, etc., can solve problems such as damaged materials and equipment, and achieve the effect of simplifying the dispersing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

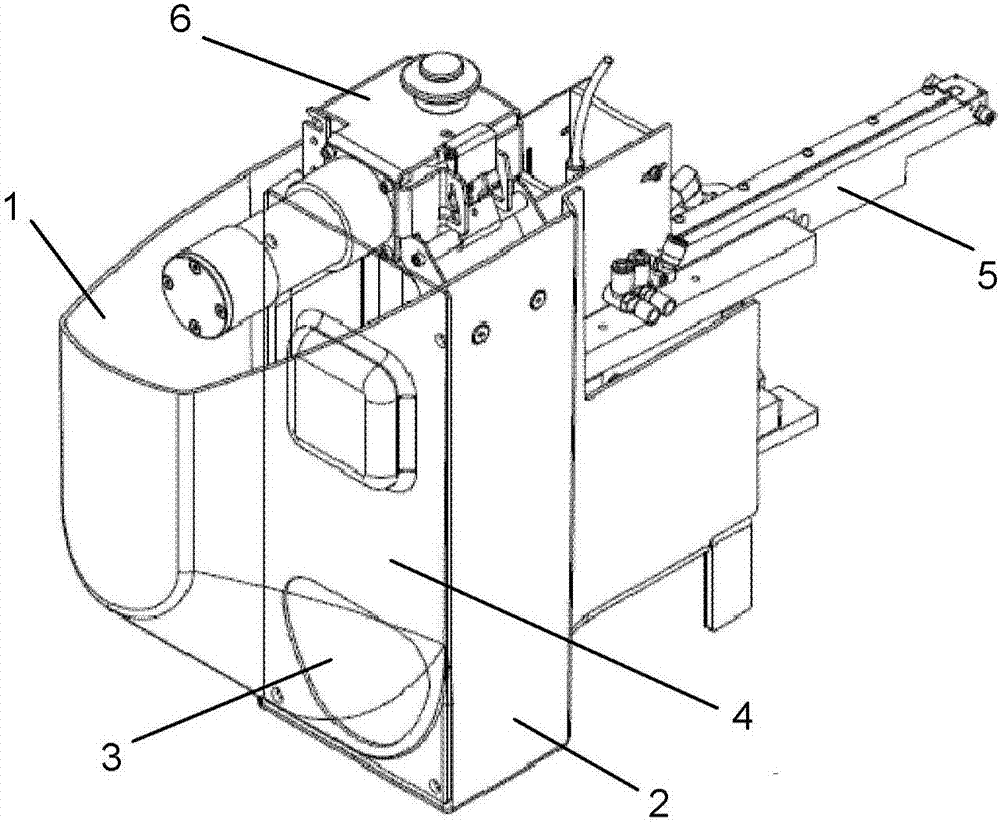

[0026] figure 1 A device for installing a cable bushing to a cable is shown in the form of an equipment part that is common in the business. The cable sleeve is contained in the charging container 1 in a loosely piled manner. The conveying device 2 receives the cable sleeve through the opening 3 in the lower part of the partition wall 4, and conveys it upwards in the vertical direction to the conveying position of the conveying device 3 in the upper area of the device 5, so as to continue conveying to the installation of the cable sleeve to the cable Installation location. The conveying device 2 has a continuous endless conveying unit that extends into the charging container 1, for example, an endless conveyor belt with a loop for containing the contents. The conveying unit is outside the conveying device 2 by a drive device 6, preferably The upper part is driven.

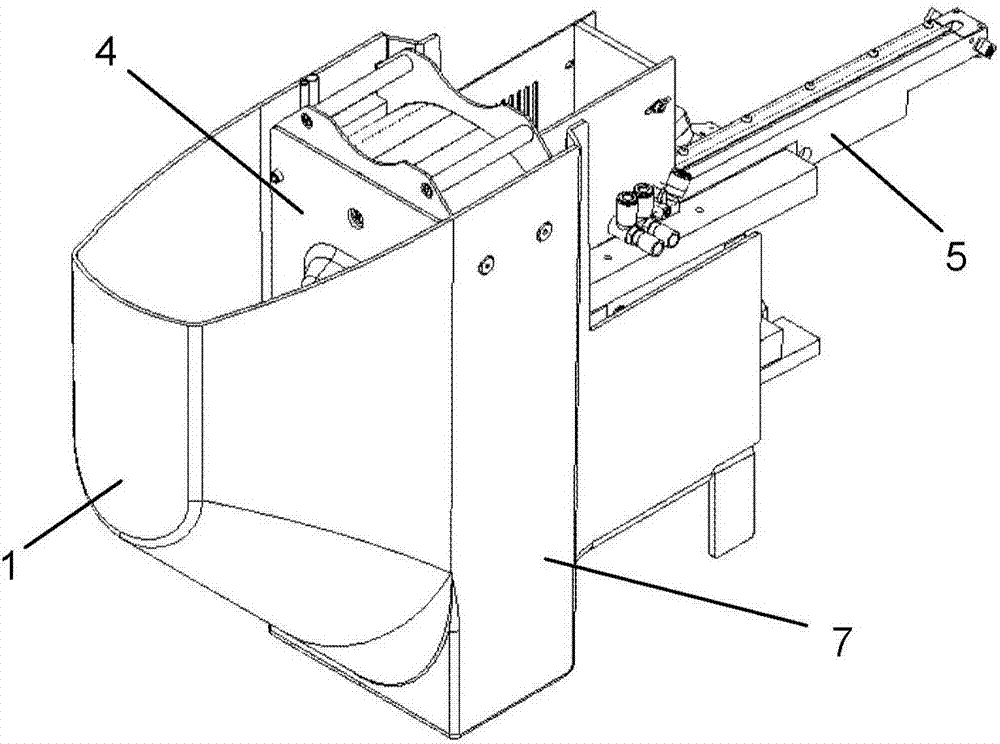

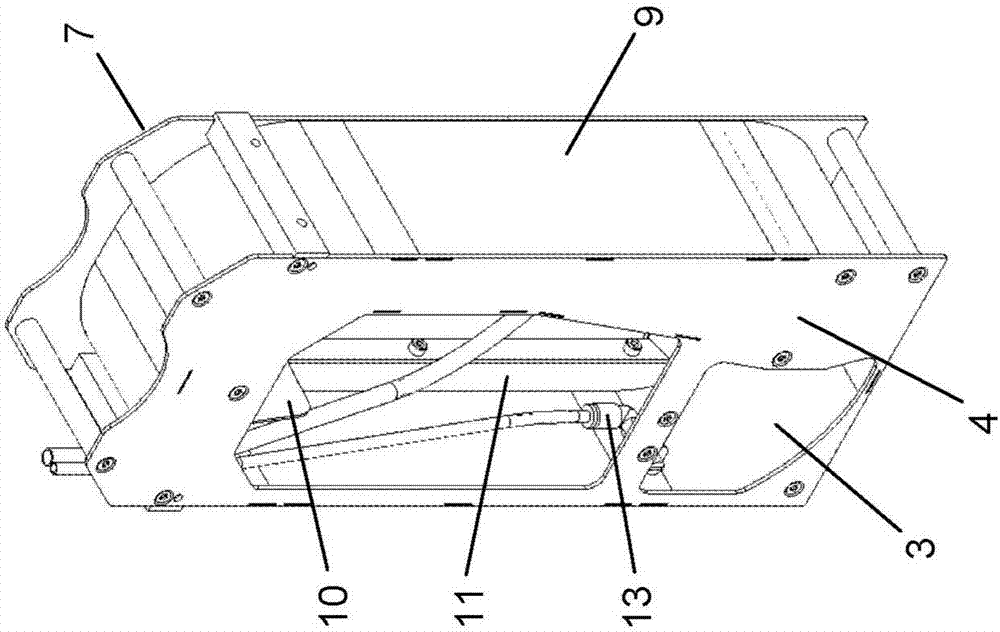

[0027] Such as figure 2 As shown, the device 7 for separating and transporting blocks from the filling contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com