A foldable stacking waste cleaning machine

A foldable, waste-removing technology, which is applied in the direction of stacking receiving devices, thin material handling, and sending objects, can solve the problem of a large space occupied by the waste-removing machine, and achieve the effect of saving the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

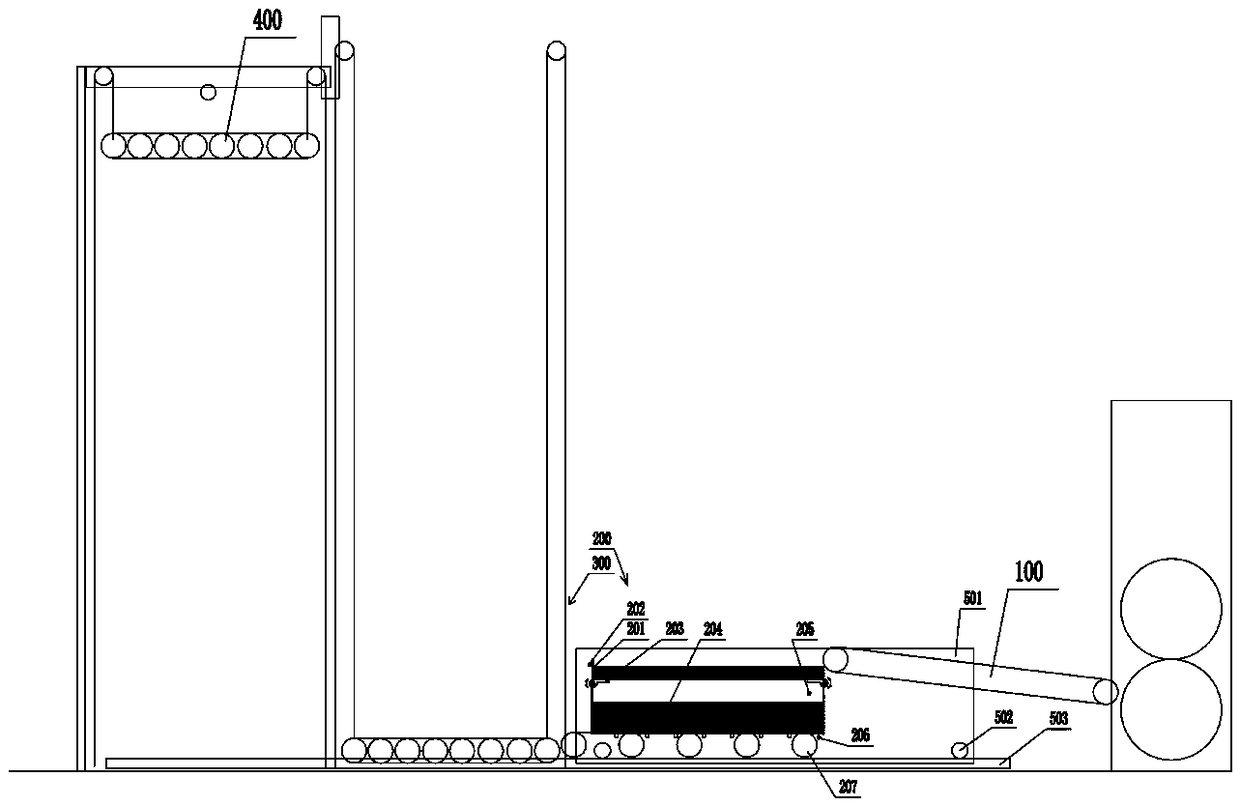

[0036] Such as figure 2 As shown, a folding and stacking waste stripping machine includes a conveyor belt mechanism 100 , a delivery mechanism 200 , a lifting mechanism 300 and a stacking mechanism 400 connected in sequence.

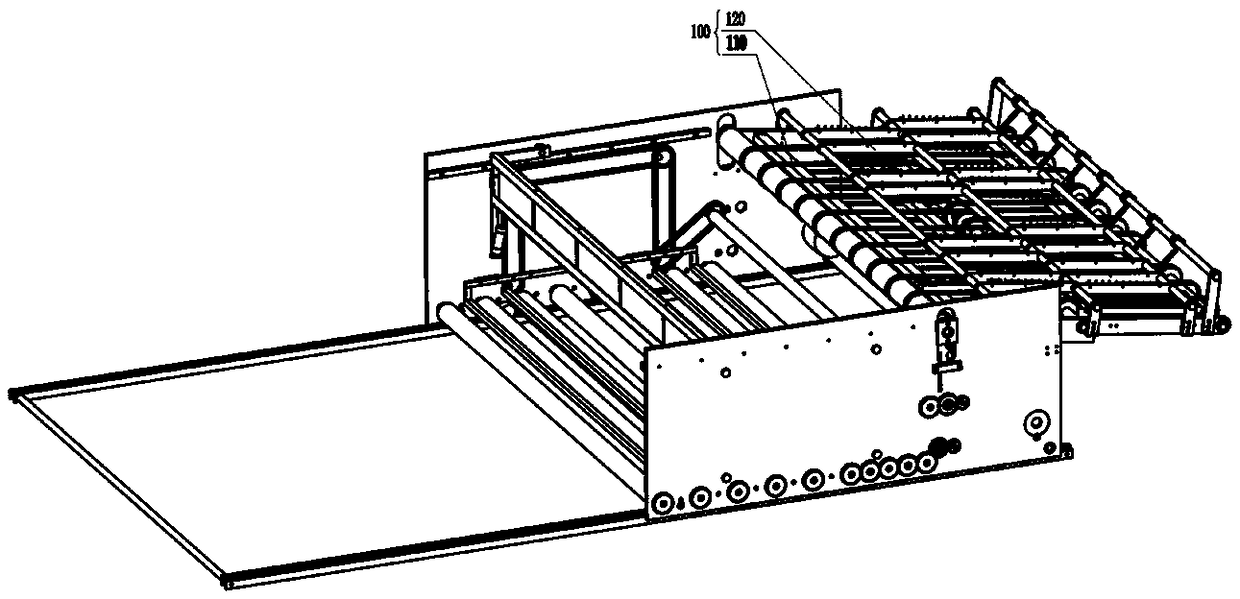

[0037] Such as image 3 As shown, the conveyor belt mechanism 100 includes a paper receiving station 110 and a waste stripping device 120 .

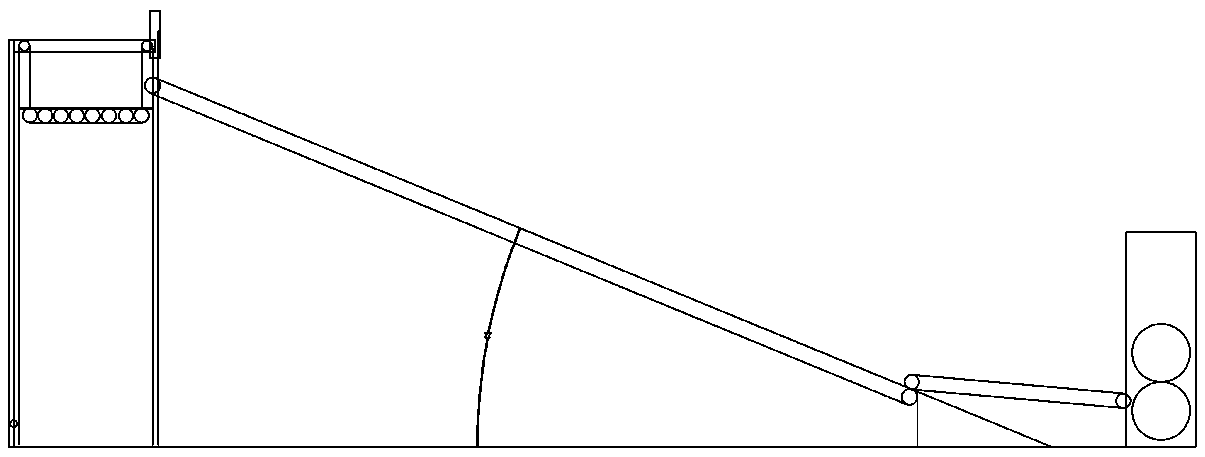

[0038] The paper receiving station 110 is provided with a conveyor belt. At least one waste removal device 120 is arranged above the paper receiving platform 110 . The paper receiving table 110 can also be placed flat or inclined, and the output end of the paper receiving table 110 is located above the input end of the paper delivery mechanism 200 . The paper receiving station 110 is different from traditional conveying devices. Transmission conveyors, such as figure 1 As shown, in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com