Auxiliary wood board stacking device for furniture production

A technology for boards and boards, applied in the field of auxiliary stacking board and board devices for furniture production, can solve the problems of time-consuming and laborious, board collision damage, low stacking height, etc., so as to reduce production costs, reduce workload, and increase stacking height. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

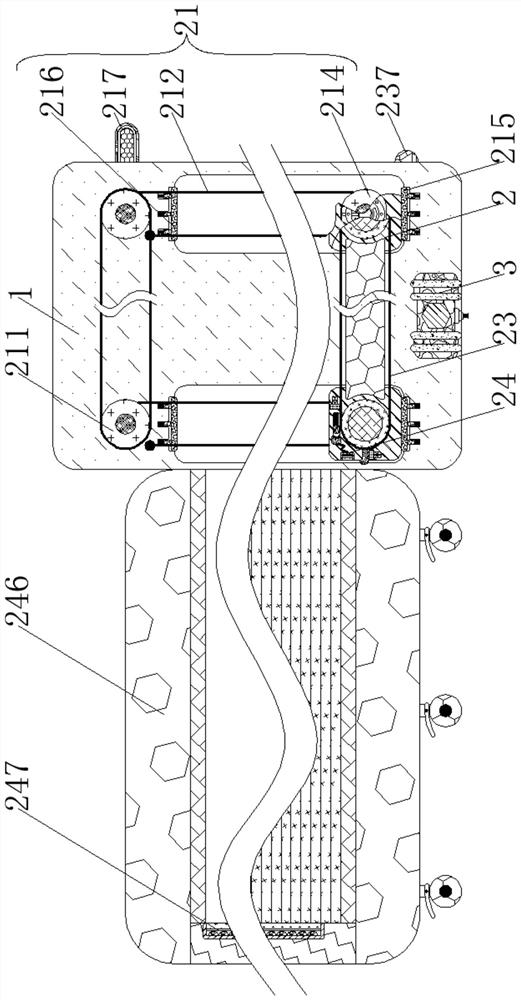

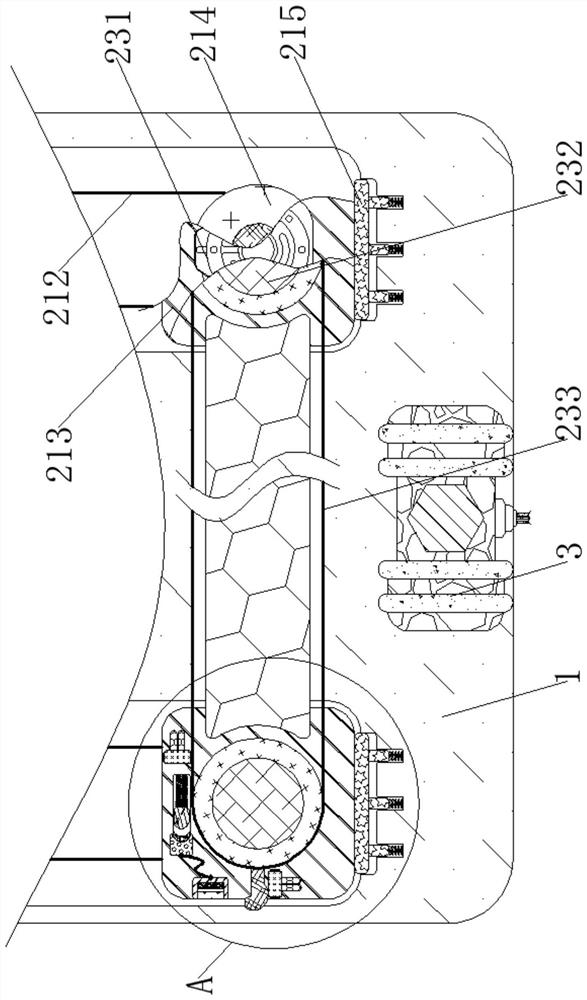

[0024] see Figure 1-4 , an auxiliary device for stacking wood boards and boards for furniture production, comprising a housing 1, a board stacking mechanism 2 is arranged inside the housing 1, and the board stacking mechanism 2 includes a lifting assembly 21, a direction changing assembly 22, a transmission assembly 23, a detection assembly 24, and the housing The inside of 1 is provided with a lifting assembly 21 that drives the lifting of the plank. The lifting assembly 21 includes a winding wheel 211, a lifting rope 212, a sliding block 213, a rotating wheel 214, a lower touch plate 215, an upper touch plate 216, a buzzer 217, and a shell The inside of 1 is rotatably connected with a winding wheel 211, the lifting rope 212 is fixedly connected to the outside of the rewinding wheel 211, the sliding block 213 is slidably connected to the inside of the housing 1, the rotating wheel 214 is rotatably connected to the outside of the sliding block 213, and the lower touch plate 2...

Embodiment 2

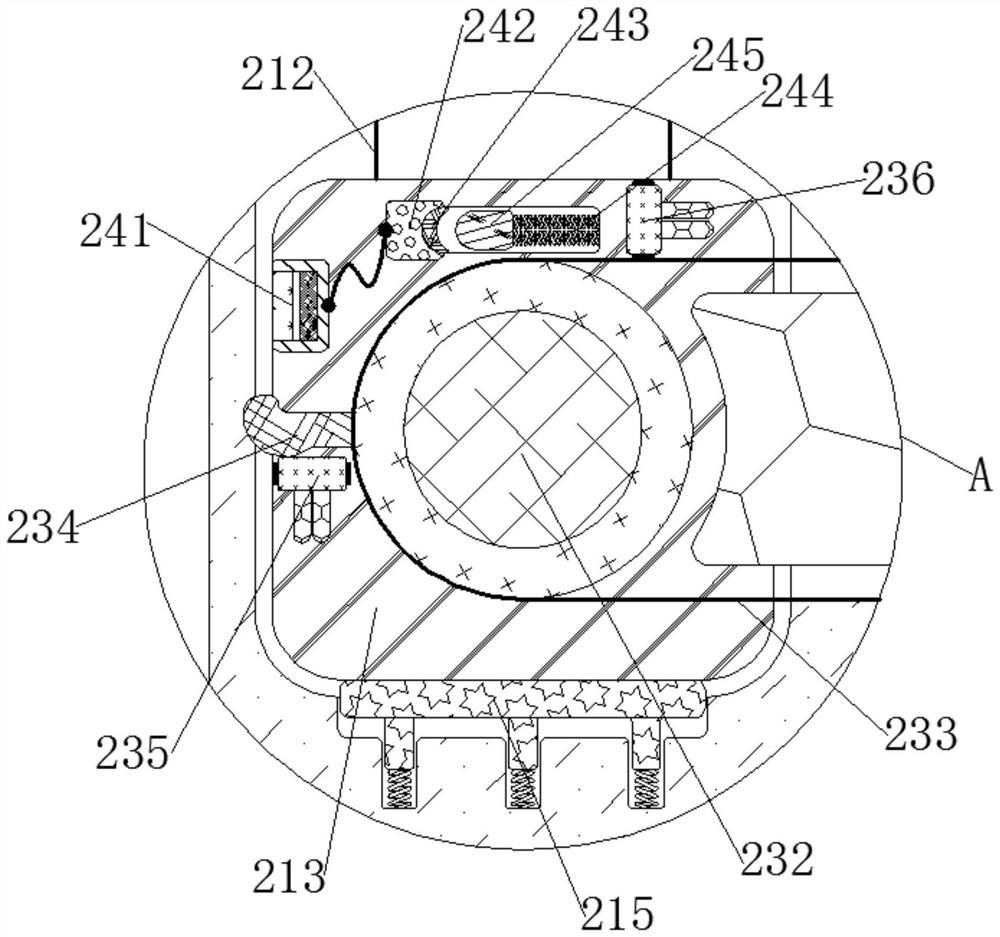

[0029] see figure 1 , 3 , an auxiliary device for stacking wood boards and boards for furniture production, comprising a housing 1, a board stacking mechanism 2 is arranged inside the housing 1, and the board stacking mechanism 2 includes a lifting assembly 21, a direction changing assembly 22, a transmission assembly 23, a detection assembly 24, and the housing 1 is provided with a lifting assembly 21 that drives the planks to move up and down, and the outside of the lifting assembly 21 is provided with a direction-changing assembly 22 that drives the lifting assembly 21 to move. The detection assembly 24 that triggers the movement of the transmission assembly 23 is provided. The detection assembly 24 includes a photoresistor 241, an electromagnet 242, a contact 243, a spring 244, an iron block 245, a pallet truck 246, a direct light strip 247, and the inside of the sliding block 213. The photoresistor 241 is fixedly connected, the electromagnet 242 is fixedly connected insi...

Embodiment 3

[0032] see Figure 1-4 , an auxiliary device for stacking wood boards and boards for furniture production, comprising a housing 1, a board stacking mechanism 2 is arranged inside the housing 1, and the board stacking mechanism 2 includes a lifting assembly 21, a direction changing assembly 22, a transmission assembly 23, a detection assembly 24, and the housing The inside of 1 is provided with a lifting assembly 21 that drives the lifting of the plank. The lifting assembly 21 includes a winding wheel 211, a lifting rope 212, a sliding block 213, a rotating wheel 214, a lower touch plate 215, an upper touch plate 216, a buzzer 217, and a shell The inside of 1 is rotatably connected with a winding wheel 211, the lifting rope 212 is fixedly connected to the outside of the rewinding wheel 211, the sliding block 213 is slidably connected to the inside of the housing 1, the rotating wheel 214 is rotatably connected to the outside of the sliding block 213, and the lower touch plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com