A kind of preparation method of star polyurethane elastomer

A technology of polyurethane elastomer and body, applied in the field of polyurethane elastomer and its preparation, can solve the problems of low material strength and complicated synthesis process of star-shaped polyurethane, and achieve better mechanical properties, efficient and controllable synthesis, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of a star polyurethane elastomer, comprising the following two methods:

[0023] Bulk one-step method: Add macromolecular diols, small molecular polyols or macromolecular polyols (functionality > 2), and chain extenders into the reaction vessel, stir at 70-130°C for 0.5-3 hours, Add diisocyanate, continue to stir for 1-10min, pour it into a material tray, put it in an oven at 100-140℃ for vulcanization for 4-24h, make the polymerization reaction complete, cool down, take it out, and obtain a star-shaped polyurethane elastomer;

[0024] Bulk prepolymerization method: Add macromolecular diols, small molecular polyols or macromolecular polyols, and diisocyanate into the reaction vessel, stir at 70-130°C for 1-6h to make a prepolymer; then Stir the prepolymer at 70-120°C and add a chain extender, pour the solution into the prepared mold when it is viscous, and press and vulcanize at 110-130°C for 10-60 minutes when it is gelled; finally, put The obtain...

Embodiment 1

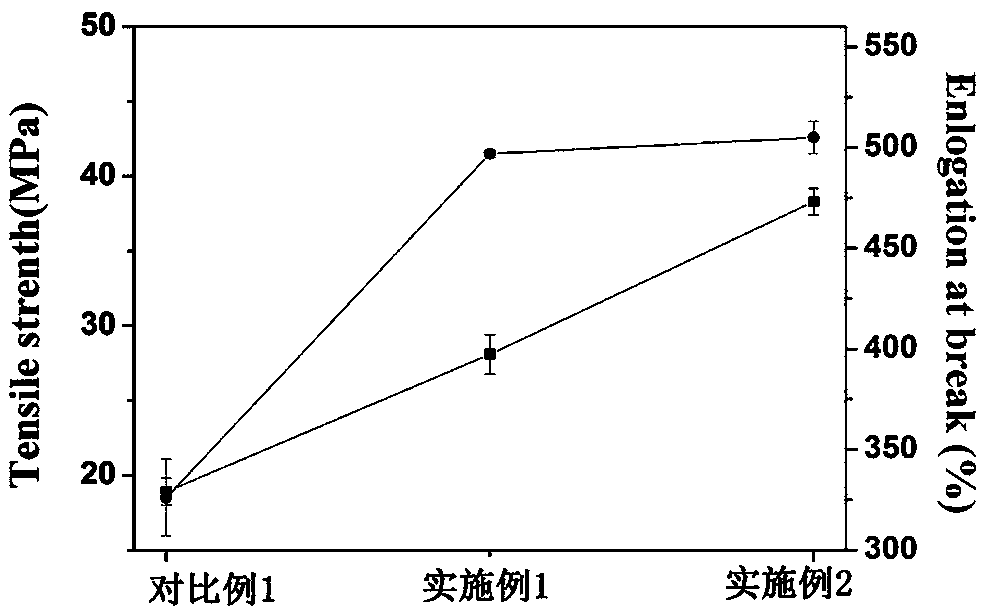

[0042] Add 98.5 parts of polypropylene glycol with a number average molecular weight of 1000, 0.3 parts of polypropylene ether triol with a number average molecular weight of 300, and 75 parts of diphenylmethane diisocyanate into a three-necked flask, slowly heat to 70°C and stir for 3 hours to prepare prepolymer. Then control the prepolymer at 70-75°C, add 18 parts of butanediol under stirring, pour the solution into the prepared mold when it is viscous, and mold it at 120°C for 40 minutes when it gels. Finally, the obtained sample was placed in an oven at 110°C for post-curing for 20 hours. The tensile strength of the star polyurethane elastomer is 28.1MPa, and the elongation at break is 496%.

Embodiment 2

[0044] Add 95.5 parts of polypropylene glycol with a number average molecular weight of 1000, 0.9 parts of polypropylene ether triol with a number average molecular weight of 300, and 75 parts of diphenylmethane diisocyanate into a three-necked flask, slowly heat to 80°C and stir for 2 hours to prepare prepolymer. Then control the prepolymer at 80-85°C, add 18 parts of butanediol under stirring, pour the solution into the prepared mold when it is viscous, and mold it at 120°C for 40 minutes when it gels. Finally, the obtained sample was placed in an oven at 110°C for post-curing for 20 hours. The star-shaped polyurethane elastomer has a tensile strength of 38.7 MPa and an elongation at break of 510%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com