Preparation method of ZIF-21 crystal

A ZIF-21, crystal technology, applied in the field of nanomaterial preparation, can solve the problems of uneven particle size, high heating temperature, long reaction time, etc., and achieve the effect of uniform particle size, low reaction temperature and short time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

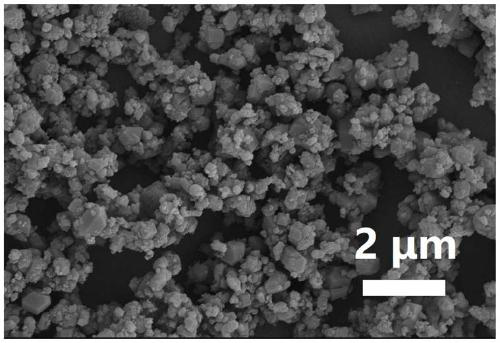

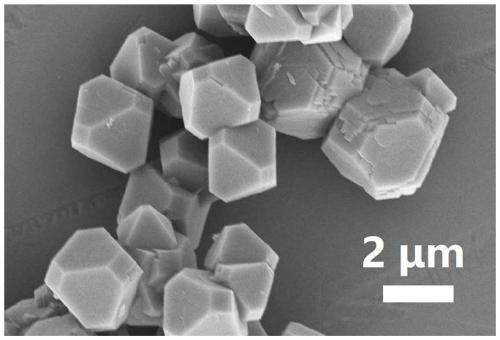

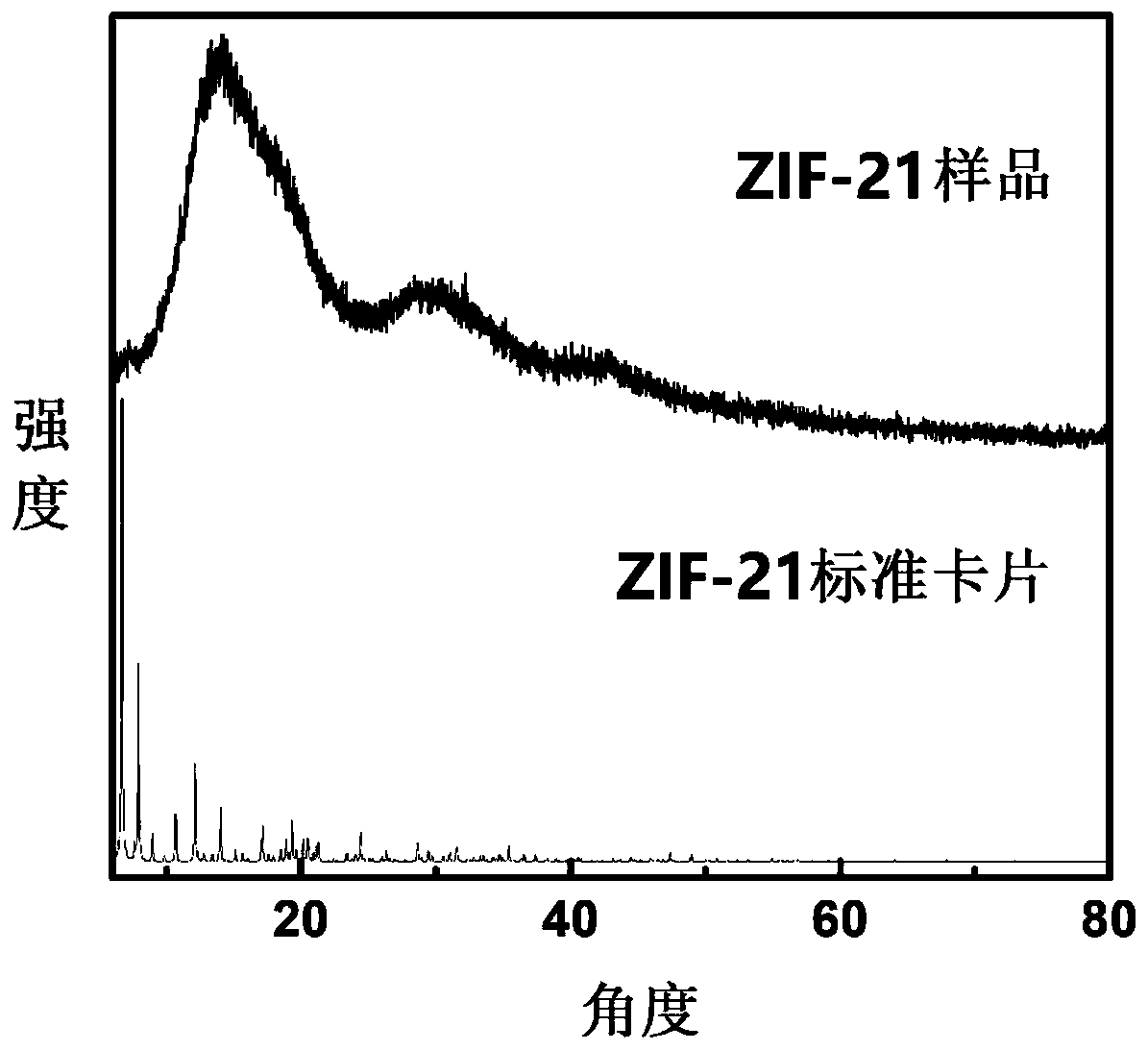

[0022] Example: at room temperature, measure 0.5 mL of DMF and place it in a vial, weigh Co(NO 3 ) 2 ∙6H 2 O 13 mg, poured into a vial filled with 0.5 mL of DMF, and placed on a magnetic stirrer, started stirring, and set aside. Measure 0.5 mL of DMF into another vial, weigh 30 mg of purine, and pour it into it. After the solution is clarified, use a 1 mL syringe to draw the DMF solution of purine, and gradually drop it in at a rate of 3-4 drops / s Cobalt nitrate solution in DMF. Then use another syringe to draw 0.2 mL of dimethylamine in methanol solution and inject it into the above solution. After continuing to stir for 30 min, put it into an ultrasonic cleaner, set the temperature to 45 °C, and continue ultrasonication for 6 h. After the end, add an appropriate amount of absolute ethanol-water (volume ratio 1:1) to disperse, and centrifuge, and repeat several times of centrifugation and washing.

[0023] Scanning electron microscopy (SEM) was carried out on the above p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com