Synthesis method of monoclinic crystal phase rare-earth iso-oxy-sulfur superfine nanowire and wire-based superstructure

An ultra-fine nano, synthetic method technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of weak S affinity, reduced lattice symmetry, and difficulty, and achieve good luminescence. The effect of performance, good universality, efficient development and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 0.20~6.0g Y(NO 3 ) 3 6H 2 O solid, 0.10-4.50 g thiourea solid, 2-10 mL oleic acid (Aldrich, 90%), 2-10 mL dodecylamine (Alfa Aesar, 98%), and 5-20 mL octadecene (Alfa Aesar , 90%), sealed the reactor and transferred it to an oven, and raised it from room temperature to 180 °C at a rate of 4 °C / min. After 24 h of reaction, the temperature was naturally cooled to room temperature. To obtain a light brown jelly, add n-heptane, heat slightly, then add ethanol to precipitate, and centrifuge to separate the solid. Then the initial product was washed with a mixed solvent of n-heptane / absolute ethanol (volume ratio: 2 / 1), and a precipitate was obtained after centrifugation. Washing was repeated 3-5 times to obtain a light yellow-green solid product, and finally the washed product was vacuum-dried at 60°C for 4 h.

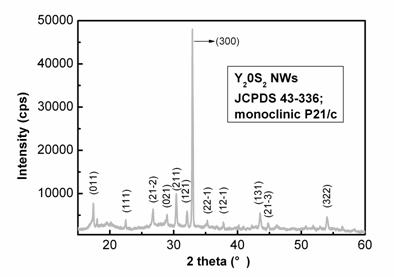

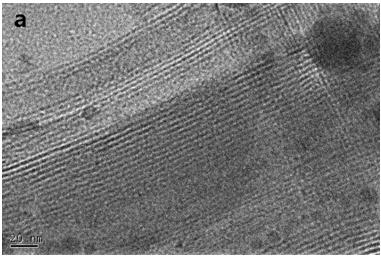

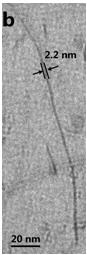

[0034] The dried product was collected, and its composition and phase were tested by X-Ray powder diffractometer (XRD). The results showed that the obtained ...

Embodiment 2

[0036] Add 0.2-6.0 g Gd(NO 3 ) 3 6H 2 O solid, 0.10-4.50g thiourea solid, 2-10 mL oleic acid, 2-10 mL dodecylamine and 5-20 mL octadecene, seal the reaction kettle and transfer it to an oven at 4 ℃ / min The rate was increased from room temperature to 180 °C. After 24 h of reaction, the temperature was naturally cooled to room temperature, and a light brown jelly was obtained. Add n-heptane, heat slightly, then add ethanol, and centrifuge to separate the solid. Then, the obtained primary product was washed with a mixed solvent of n-heptane / absolute ethanol (volume ratio: 2 / 1), and a precipitate was obtained after centrifugation. Washing was repeated 3-5 times to obtain a light yellow-green solid product, and finally the washed product was vacuum-dried at 60°C for 4 h. .

[0037] The dried product was collected, and its composition and phase were tested by X-Ray powder diffractometer (XRD), which showed that the obtained product was pure monoclinic crystal phase structure Gd...

Embodiment 3

[0039] In a clean and dry reaction kettle (volume 50 mL) with polytetrafluoroethylene liner, add 0.2-6.0 g Dy(NO 3 ) 3 6H 2 O solid, 0.10-4.50g thiourea solid, 2-10 mL oleic acid, 2-10 mL dodecylamine and 5-20 mL octadecene, seal the reaction kettle and transfer it to an oven at 4 ℃ / min The rate was increased from room temperature to 200 °C, and after 24 h of reaction, the temperature was naturally cooled to room temperature. A light brown gum was obtained. Add n-heptane, heat slightly, then add ethanol, and centrifuge to separate the solid. Then, the obtained product was washed with a mixed solvent of n-heptane / absolute ethanol (volume ratio: 2 / 1), and a precipitate was obtained after centrifugation. The washing operation was repeated 3-5 times to obtain a light yellow-green solid product, and finally the washed product was vacuum-dried at 60 °C for 4 h.

[0040] The dried product was collected, and its composition and phase were tested by X-Ray powder diffractometer (XR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com