Waterborne polyurethane extinction resin

A technology of water-based polyurethane and matting resin, which is applied in the field of water-based polyurethane matting resin, can solve the problems of uneven matting coating, affecting product performance, and shedding of matting coating, so as to achieve excellent matting performance and avoid the effect of uneven matting coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

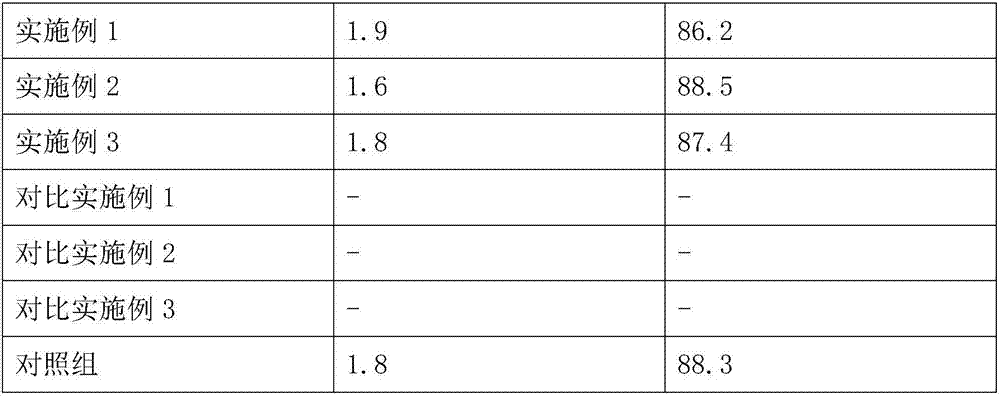

Embodiment 1

[0016] A water-based polyurethane matting resin, specifically prepared from the following components in parts by mass: 10 parts of polyisocyanate, 10 parts of polyester polyol, 0.3 part of DMPA, 0.8 part of sodium sulfonate, and 1.5 parts of hexamethylenediamine , 35 parts of glycol, 0.02 part of catalyst, 5 parts of dimethylethanolamine, 3 parts of N-methylpyrrolidone solvent, 200 parts of deionized water; its preparation method is specifically the following steps:

[0017] (1) Dry the polyester polyol and diol with hot air at 55°C for 15 minutes, then vacuum dehydrate at 80°C for 45 minutes, with a vacuum degree of 0.04MPa, so that the moisture content is less than 0.02%;

[0018] (2) Put the material obtained in step (1) into a reaction kettle, heat to 70°C, add the diisocyanate and 1 / 2 of the DMPA, keep warm for 15 minutes, then heat up to 85°C, and keep warm for 110 minutes , to make it fully react, during which the catalyst is added every 40 minutes, the first addition i...

Embodiment 2

[0023] A water-based polyurethane matting resin, specifically prepared by the following components in parts by mass: 18 parts of polyisocyanate, 30 parts of polyester polyol, 1.5 parts of DMPA, 2.4 parts of sodium sulfonate, and 2.5 parts of hexamethylenediamine , 60 parts of glycol, 0.05 part of catalyst, 7 parts of dimethylethanolamine, 9 parts of N-methylpyrrolidone solvent, 280 parts of deionized water; its preparation method is specifically the following steps:

[0024] (1) Dry the polyester polyol and diol with hot air at 65°C for 20 minutes, then vacuum dehydrate at 140°C for 60 minutes, with a vacuum degree of 0.07MPa, so that the moisture content is less than 0.02%;

[0025] (2) Put the material obtained in step (1) into the reaction kettle, heat it to 75°C, add the diisocyanate and 1 / 2 of the DMPA, keep it warm for 25 minutes, then raise the temperature to 90°C, and keep it warm for 130 minutes , to make it fully react, during which the catalyst is added every 40 min...

Embodiment 3

[0030] A water-based polyurethane matting resin, in parts by mass, specifically prepared from the following components: 15 parts of polyisocyanate, 20 parts of polyester polyol, 0.8 part of DMPA, 1.6 parts of sodium sulfonate, and 2.1 parts of hexamethylenediamine , 48 parts of glycol, 0.04 part of catalyst, 6 parts of dimethylethanolamine, 7 parts of N-methylpyrrolidone solvent, 250 parts of deionized water; its preparation method is specifically the following steps:

[0031] (1) Dry the polyester polyol and diol with hot air at 60°C for 18 minutes, then vacuum dehydrate at 120°C for 50 minutes, with a vacuum degree of 0.06MPa, so that the moisture content is less than 0.02%;

[0032] (2) Put the material obtained in step (1) into the reaction kettle, heat it to 73°C, add the diisocyanate and 1 / 2 of the DMPA, keep it warm for 20 minutes, then raise the temperature to 88°C, and keep it warm for 120 minutes , to make it fully react, during which the catalyst is added every 40 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com