Modified polyester extinction powder coating and preparation method thereof

A technology of matting powder coating and modified polyester, applied in powder coatings, polyester coatings, coatings, etc., can solve problems such as light pollution and eye damage, achieve good leveling and mechanical properties, excellent physical properties, good matting properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

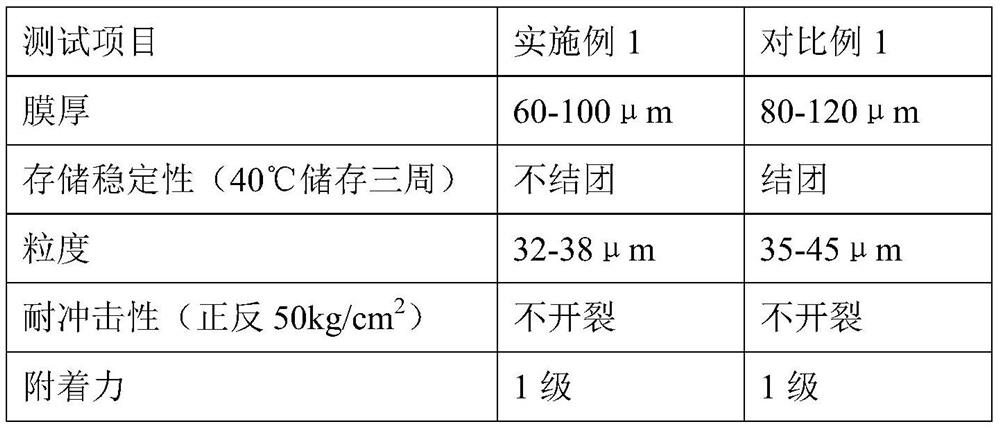

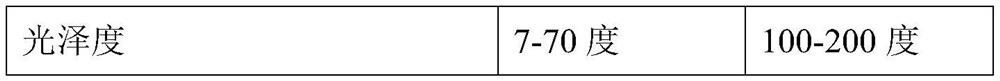

Examples

Embodiment 1

[0020] A modified polyester matting powder coating, comprising the following raw material components in percentage by weight, solid modified polyester resin 60%, curing agent triglycidyl isocyanurate 4.5%, solid pigment 7.5%, solid additives 2%, solid filler 26%, described solid modified polyester resin is that dimethyl adipate obtains polyester resin modification, and described solid filler comprises precipitated barium sulfate, 1500 mesh barium sulfate, 2000 mesh calcium carbonate and 800 mesh calcium carbonate, the weight ratio is 1:2:2:1.

[0021] The solid additives include leveling agents, defoamers, anti-wear agents and matting agents.

[0022] The solid pigment is titanium dioxide.

[0023] The invention provides a kind of preparation method of modified polyester matting powder coating, comprises the following steps,

[0024] 1) After preparing the materials, mix the raw materials and stir for 5 minutes;

[0025] 2) Pour the stirred raw materials into the extruder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com