Super heat preservation press connection exposed frame unit body curtain wall system

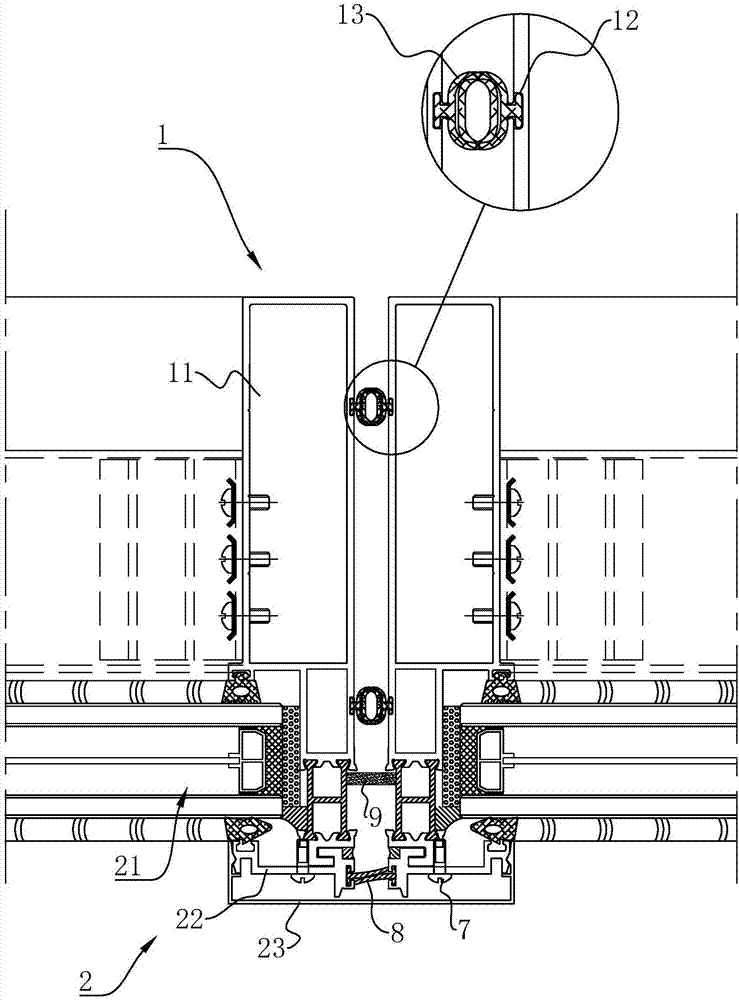

A unit body and exposed frame technology, applied to walls, building components, buildings, etc., can solve problems such as easy heat exchange, non-compliance with environmental protection and energy saving, and influence on the unit structure of curtain walls, achieving good results, ensuring thermal insulation performance, and good environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

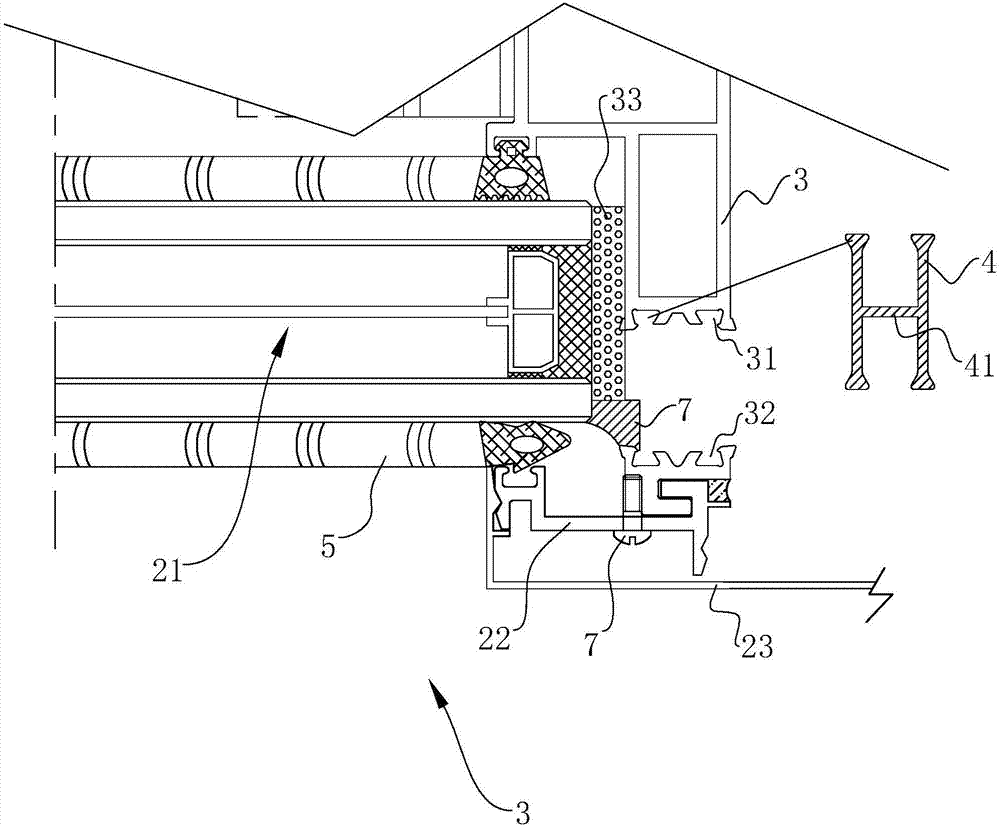

[0050] Embodiment 2: The difference from Embodiment 1 is that, as figure 1 and Figure 4 As shown, the heat-insulation strip 9 includes a first heat-insulation strip 91 and two second heat-insulation strips 92 respectively bonded to the heat-insulation strip 4 in one side of the exposed frame unit 1, and the two second An inserting groove 93 is formed between the heat insulating strips 92 , and when two exposed frame units 1 are butted and installed, the first heat insulating strip 91 is inserted into the inserting groove 93 .

Embodiment 3

[0051] Embodiment three: the difference from embodiment two is that, as figure 1 and Figure 5 As shown, the heat insulating rubber strip 9 includes a first wedge-shaped strip 100 formed with a first slope 1001 at one end and a second wedge-shaped strip 101 with a second slope 1011 formed at one end matching the first wedge-shaped strip 100. When two bright frame units 1 are docked, the first wedge-shaped strip 100 and the second wedge-shaped strip 101 are connected in relative contact, and the first slope surface 1001 and the second slope surface 1011 have the same angle and are in close contact.

Embodiment 4

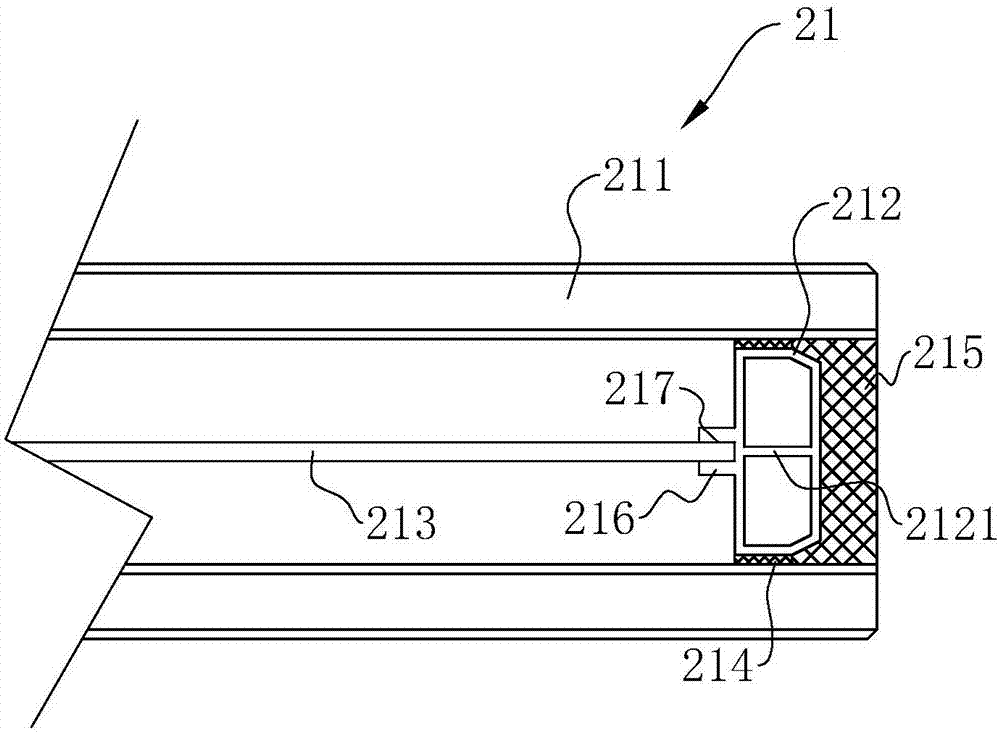

[0052] Embodiment 4: The difference from Embodiment 3 is that, as figure 1 and Figure 6 As shown, the heat insulating strip 9 includes a connection section 200 bonded to the heat insulating strip 4 and a butt section 201 fixedly connected to one end away from the heat insulating strip 4 and bifurcated to both sides. The section of the heat insulating strip 212 is In a "Y" shape, when two exposed frame units 1 are docked, the docking sections 201 are connected to each other to close the gap and cut off the heat conduction between indoor and outdoor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com