Mining TBM receding type dismounting method

A backward, mining technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high consumption, large human and financial resources, etc., and achieve the effect of reducing construction costs and simplifying construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0023] This embodiment includes the following steps:

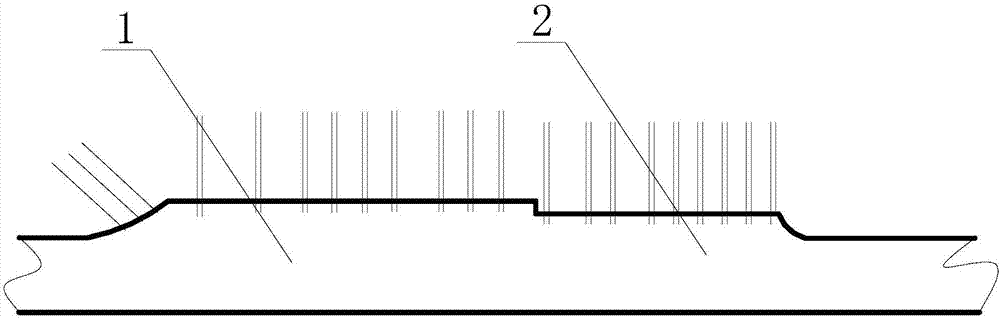

[0024] (1) After the mining TBM equipment has completed the excavation in the construction roadway, disconnect the belt conveyor in the construction roadway, then retract the belt conveyor by 40-45m, and then fire the cannon to expand the dismantling chamber. The equipment along the inner side brushes and expands the disintegration chamber to the rear, and then uses the belt conveyor and rake machine to transport the expanded gangue out;

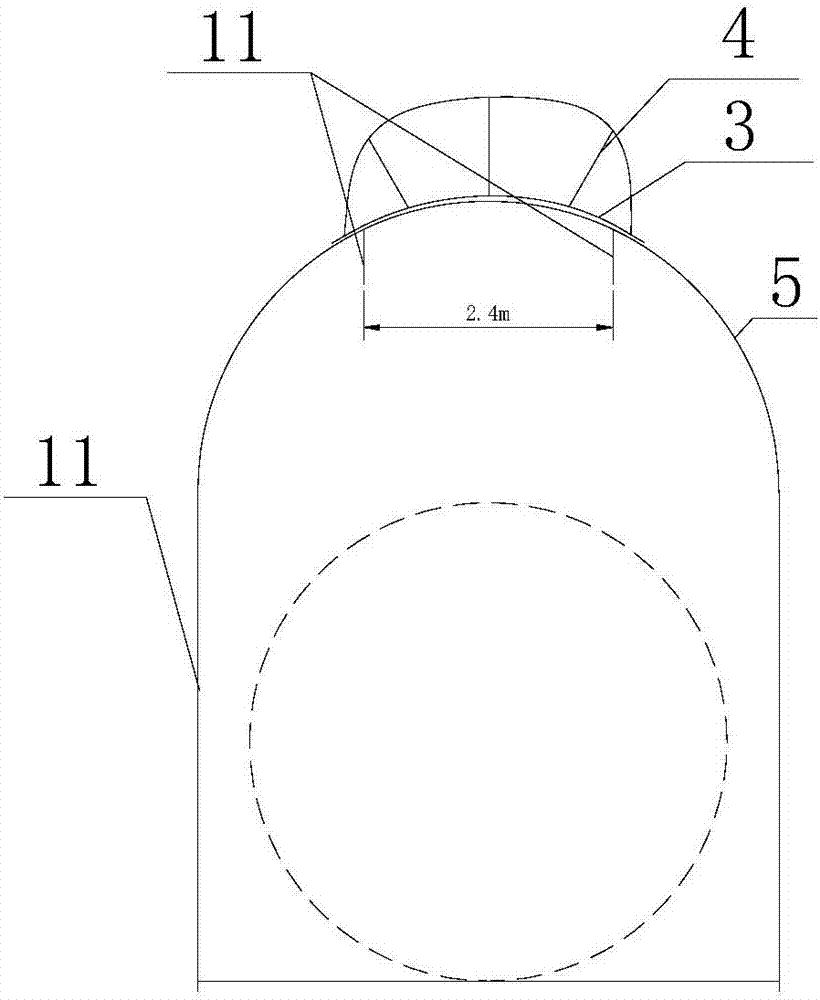

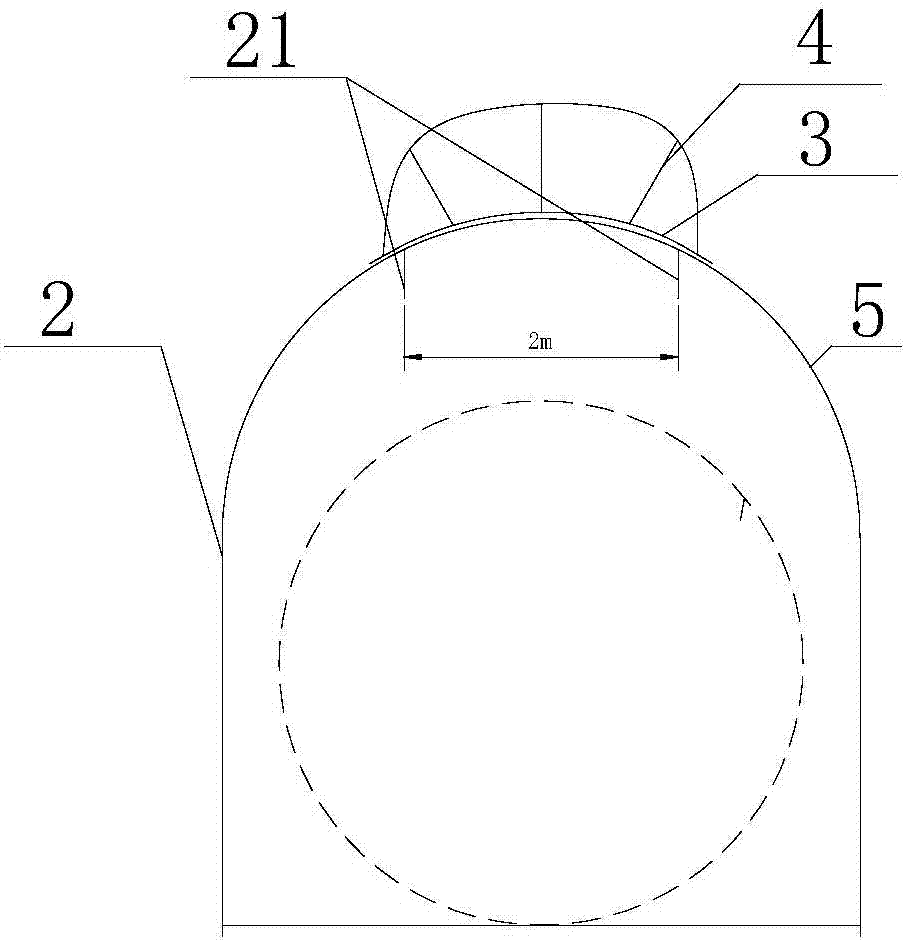

[0025] (2) First support the side support of the equipment itself on both sides of the roadway, then raise the equipment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com