Test method for water leakage of shield segment joints

A test method and technology for shield segments, which can solve problems such as water leakage by detecting the appearance of fluid at the leak point, and using liquid/vacuum for liquid tightness measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

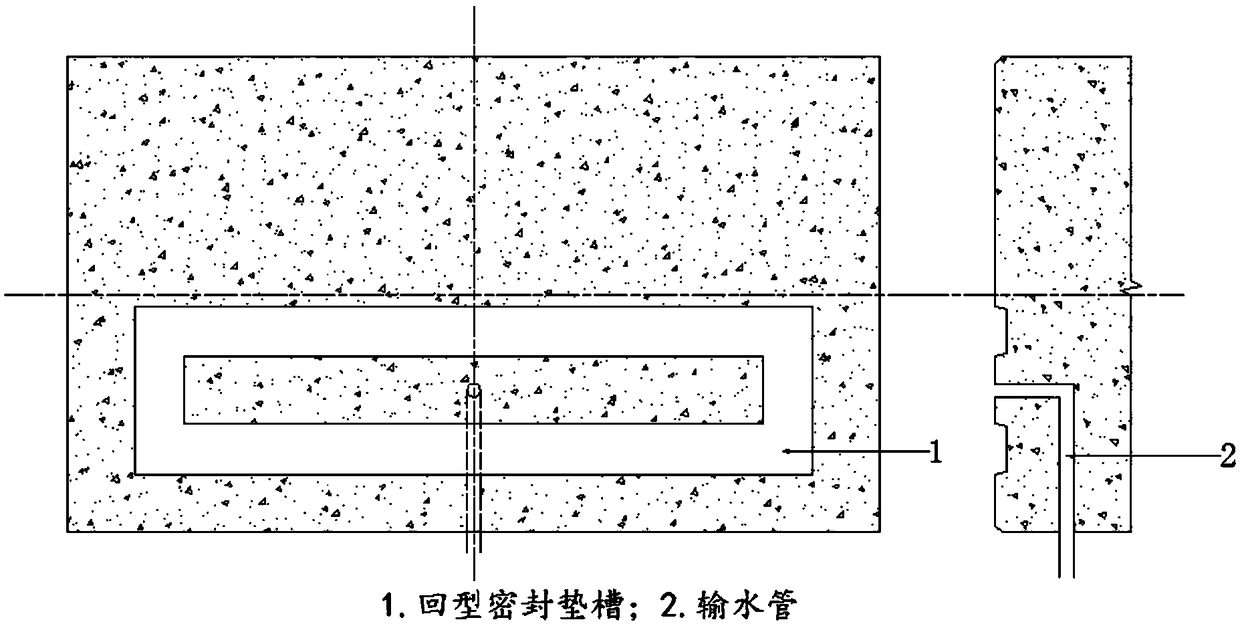

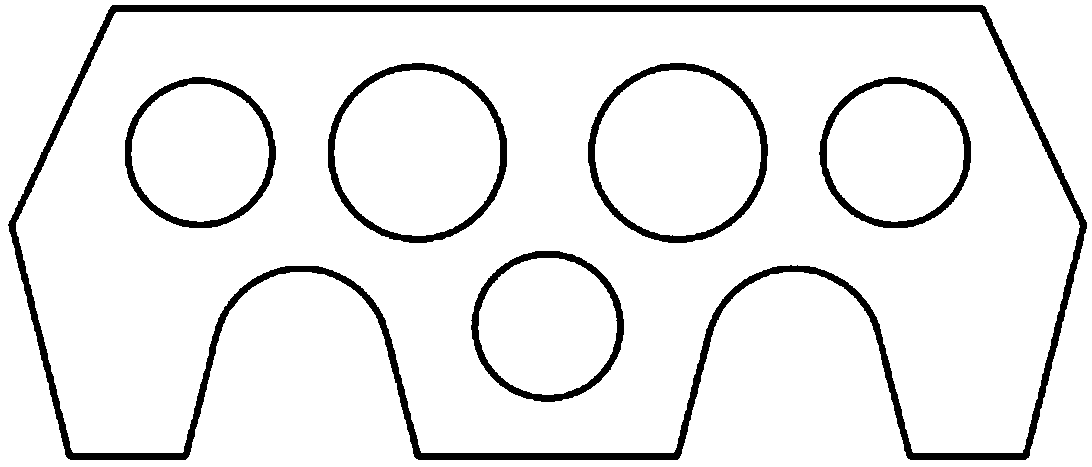

[0026] The core of the water leakage test method for the back-type gasket groove segment joint is to cut the surface of the concrete segment to form a back-type gasket groove, and use the pre-buried water pipe to conduct the test under a certain load condition or the joint opening condition. Joint leak test.

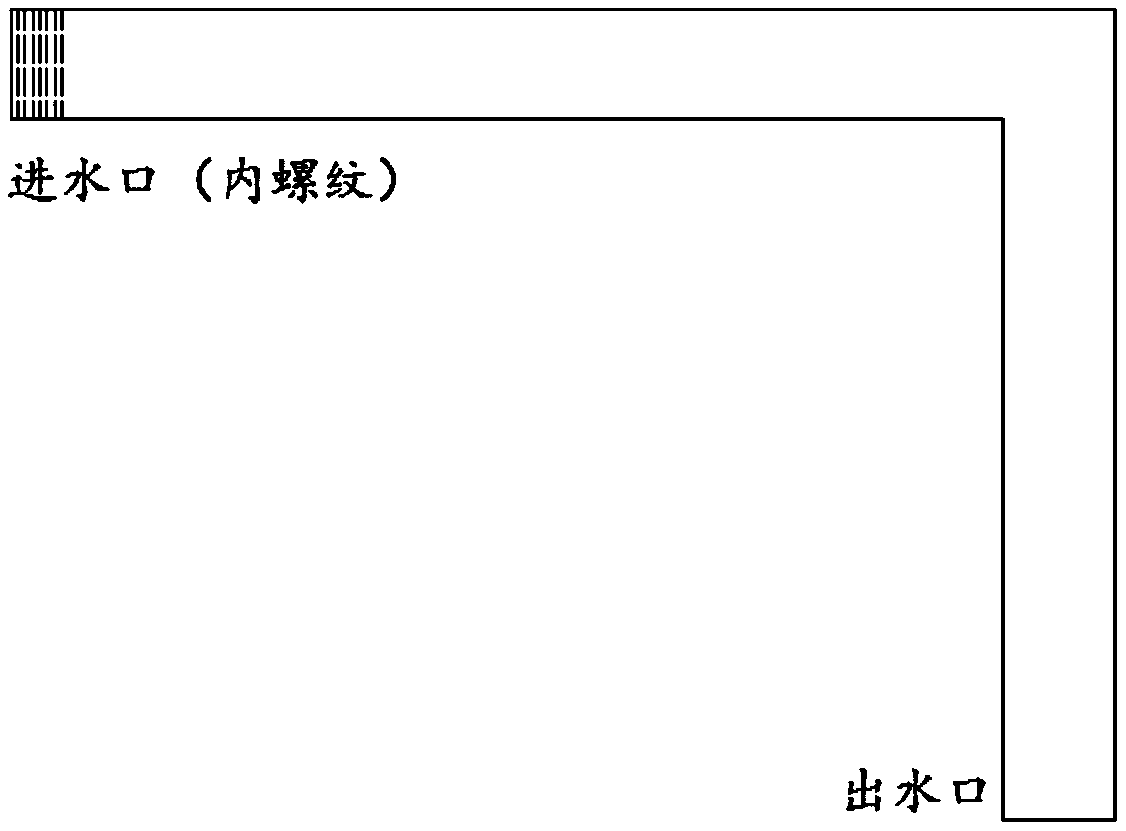

[0027] The pre-embedded water delivery pipe of the present invention is the water inlet channel for the water leakage test of the segment joint. In order to prevent the water pipe from being damaged and moved during the test, special designs must be made on the size, material and embedding method of the water pipe. Among them, steel pipes are used for water delivery pipes, and the size is mainly determined by the size of the segment and the minimum welding requirements. For details, see figure 1 . The embedding method of the water pipe requires that the A end is drawn out from the joint section, and the B end is drawn out from the outer arc surface of the segment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com