Mounting method for inverse mounting construction lifter

A technology of construction hoist and installation method, which is applied in the direction of transportation and packaging, elevators in buildings, etc., and can solve problems such as the inability to solve the problem of reverse construction hoist installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

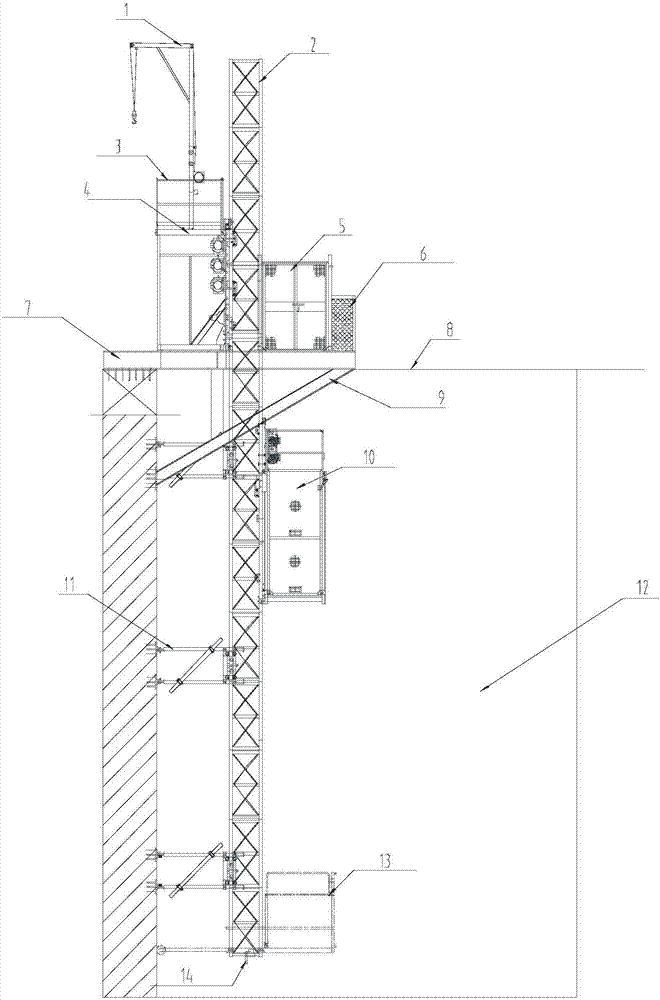

[0037] An installation method for reverse installation of construction elevators, the first step is to transport the guide rail frame cage steel structure 4, and the steel structure platform 7 is fixed and locked with bolts or welded into one;

[0038] The second step is to install the guide rail frame 2 and install the standard section;

[0039] The third step is to install the attached wall 11;

[0040] The fourth step is to install the upper limit bump block 14 and the upper limit bump block 14;

[0041] The fifth step is to debug each roller;

[0042] The sixth step is comprehensive self-inspection;

[0043] The seventh step is trial operation;

[0044] In the second step, the people-cargo construction elevator drives to the level of the ground 8 and stops on the guide rail frame 2. At this time, the people-cargo elevator 10 is unloaded, and the crane on the steel structure 4 of the delivery guide rail frame hanging cage Rod 1 is equipped with standard joints on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com