Multi-groove photocatalyst ceramic plate

A ceramic plate and photocatalyst technology, applied in the field of ceramic plates, can solve the problems of difficult disposal of waste, high cost, inability to handle chemicals, etc., and achieves the effects of easy cleaning, decomposing odors, and preventing dirt from adhering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

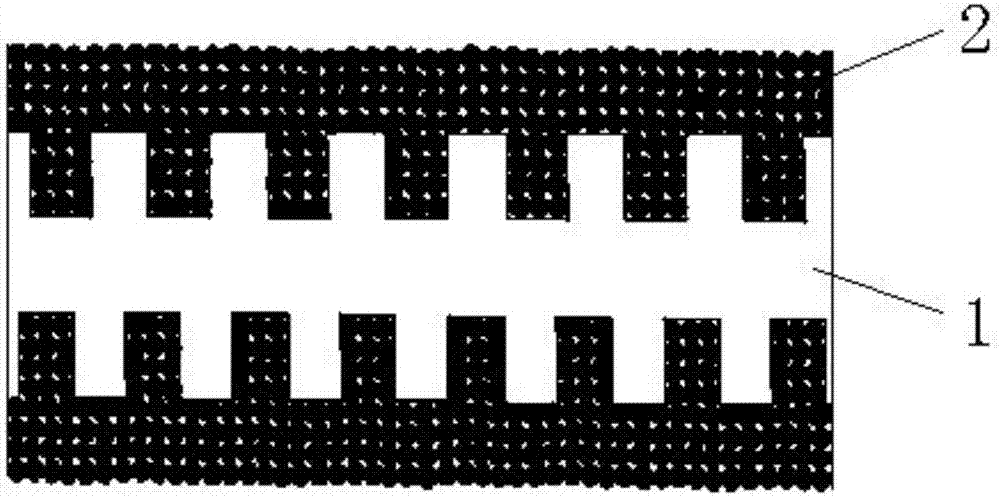

[0026] refer to figure 1 , a kind of porous type photocatalyst ceramic plate, comprises porous type ceramic plate 1, and its thickness is 5mm, and the whole interior of porous type ceramic plate 1 is interconnected by the small hole that size is 50 μ m and is three-dimensional network structure, and its porous type The porosity of the type ceramic plate 1 is 91%, and its surface is provided with a plurality of concave grooves, and the surface of the porous type ceramic plate 1 is provided with a nano-titanium dioxide photocatalyst material layer 2, and the surface of the nano-titanium dioxide photocatalyst material layer 2 is embedded with metal particles.

[0027] The thickness of the nano titanium dioxide photocatalyst material layer is 1 μm, and the particle diameter of the titanium dioxide particles in the nano titanium dioxide photocatalyst material layer is 5 nm.

[0028] Its preparation method comprises the following steps:

[0029] Step 1: Make multi-hole ceramic plat...

Embodiment 2

[0036] refer to figure 1 , a kind of porous type photocatalyst ceramic plate, comprises porous type ceramic plate 1, and its thickness is 8mm, and the whole interior of porous type ceramic plate 1 is interconnected by the small hole that size is 60 μ m and is three-dimensional network structure, and its porous type The porosity of the formula ceramic plate 1 is 93%, and its surface is provided with a plurality of concave grooves, and the surface of the porous ceramic plate 1 is provided with a nano-titanium dioxide photocatalyst material layer 2, and the surface of the nano-titanium dioxide photocatalyst material layer 2 is embedded with metal particles.

[0037] The thickness of the nano-titanium dioxide photocatalyst material layer is 2 μm, and the particle diameter of the titanium dioxide particles in the nano-titanium dioxide photocatalyst material layer is 8 nm.

[0038] Its preparation method comprises the following steps:

[0039] Step 1: Make multi-hole ceramic plates...

Embodiment 3

[0045] refer to figure 1 , a kind of porous type photocatalyst ceramic plate, comprises porous type ceramic plate 1, and its thickness is 12mm, and the whole interior of porous type ceramic plate 1 is interconnected by the small hole that size is 70 μ m and is three-dimensional network structure, and its porous type The porosity of the ceramic plate is 95%, and its surface is provided with a plurality of concave grooves. The surface of the porous ceramic plate 1 is provided with a nano-titanium dioxide photocatalyst material layer 2, and the surface of the nano-titanium dioxide photocatalyst material layer 2 is embedded with metal particles.

[0046] The thickness of the nano titanium dioxide photocatalyst material layer is 3 μm, and the particle diameter of the titanium dioxide particles in the nano titanium dioxide photocatalyst material layer is 12 nm.

[0047] Its preparation method comprises the following steps:

[0048] Step 1: Make multi-hole ceramic plates, use bauxit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com