Green steel face revetment and manufacturing method thereof

A manufacturing method and steel surface technology, applied in botanical equipment and methods, excavation, coastline protection, etc., can solve problems such as slope protection environment, beautification and disharmony, and achieve the effect of pleasing the body and mind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

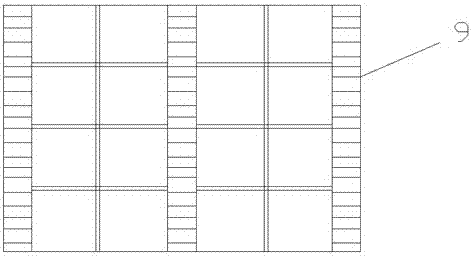

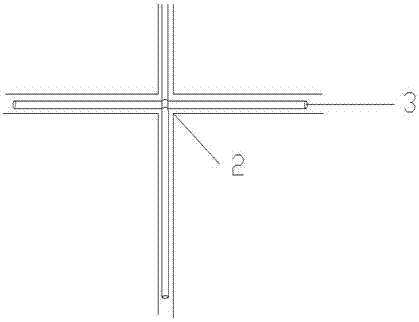

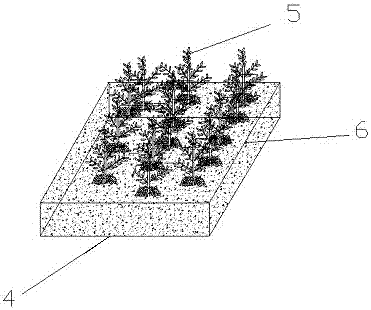

[0032] Embodiment 1: as Figure 1-4 Shown, a kind of green steel face slope protection comprises steel channel 2, fluorescent lamp circuit 3, organic soil 4, plant 5, steel surface 7, slope body 8, steel ladder 9; The upper surface of described slope body 8 is provided with steel Surface 7, the left, middle and right sides of the steel surface 7 are provided with longitudinal steel ladders 9, the steel surface 7 between adjacent steel ladders 9 is provided with horizontally and vertically superimposed steel channels 2, and between adjacent steel channels 2 A rectangular steel surface 7 is formed between the steel channel 2 and the connected steel ladder 9. Organic soil 4 is laid on the rectangular steel surface 7. Plants 5 are planted on the organic soil 4. The steel channel 2 A fluorescent lamp line 3 is installed inside, and the organic soil 4 is mixed with spices 6 .

[0033] The steel surface 7 is fixed on the upper surface of the slope body 8 by screws 1 , the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com